Sliding table mechanism utilizing hydraulic cylinder and gear to realize double-speed movement

A sliding table mechanism, double-speed technology, applied in the field of machinery, to achieve the effects of lightweight product structure, increased service life, and reduced piston feed speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

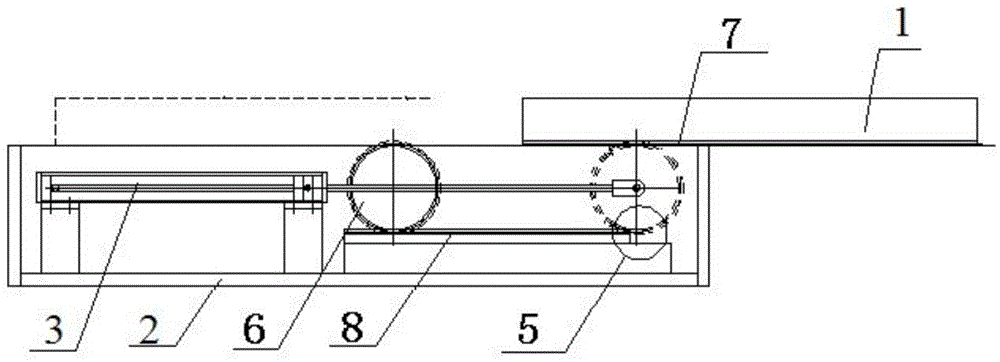

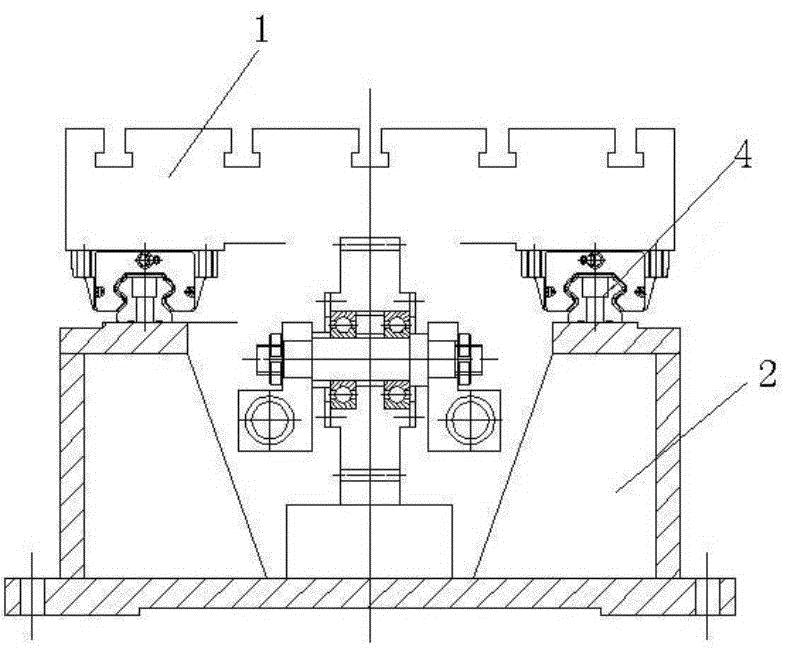

[0030] Such as figure 1 , figure 2 , as shown, a sliding table mechanism utilizing hydraulic cylinders and gears to move at double speed in this patent includes a controller, a sliding table body 1 and a sliding table mechanism;

[0031] The slide mechanism includes a slide base 2, a linear guide rail 4, a drive gear 6, a drive cylinder 3, a slide body rack 7, and a slide base rack 8; the controller is set on the slide base 2 to control the drive cylinder 3 to drive The gear 6 acts; the driving cylinder 3 is a one-way cylinder, and the driving cylinder 3 includes a cylinder body and a telescopic cylinder, the cylinder body is arranged at the bottom of the slide base 2, and the telescopic cylinder includes a power output end; the driving gear 6 is provided with a rotating shaft in the middle, and the rotating shaft It is fixed at the power output end of the telescopic oil cylinder.

[0032] Two linear guide rails 4 are arranged in parallel on the slide base 2; the lower part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com