Upper Shoulder Bowl Compression Molding Type Shoulder Injection Machine

A molding type, shoulder injection machine technology, applied in coating and other directions, can solve the problems of inconvenient mold replacement, low production efficiency, high cost of use, and achieve the effects of easy dust-free sterilization, high production efficiency, and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

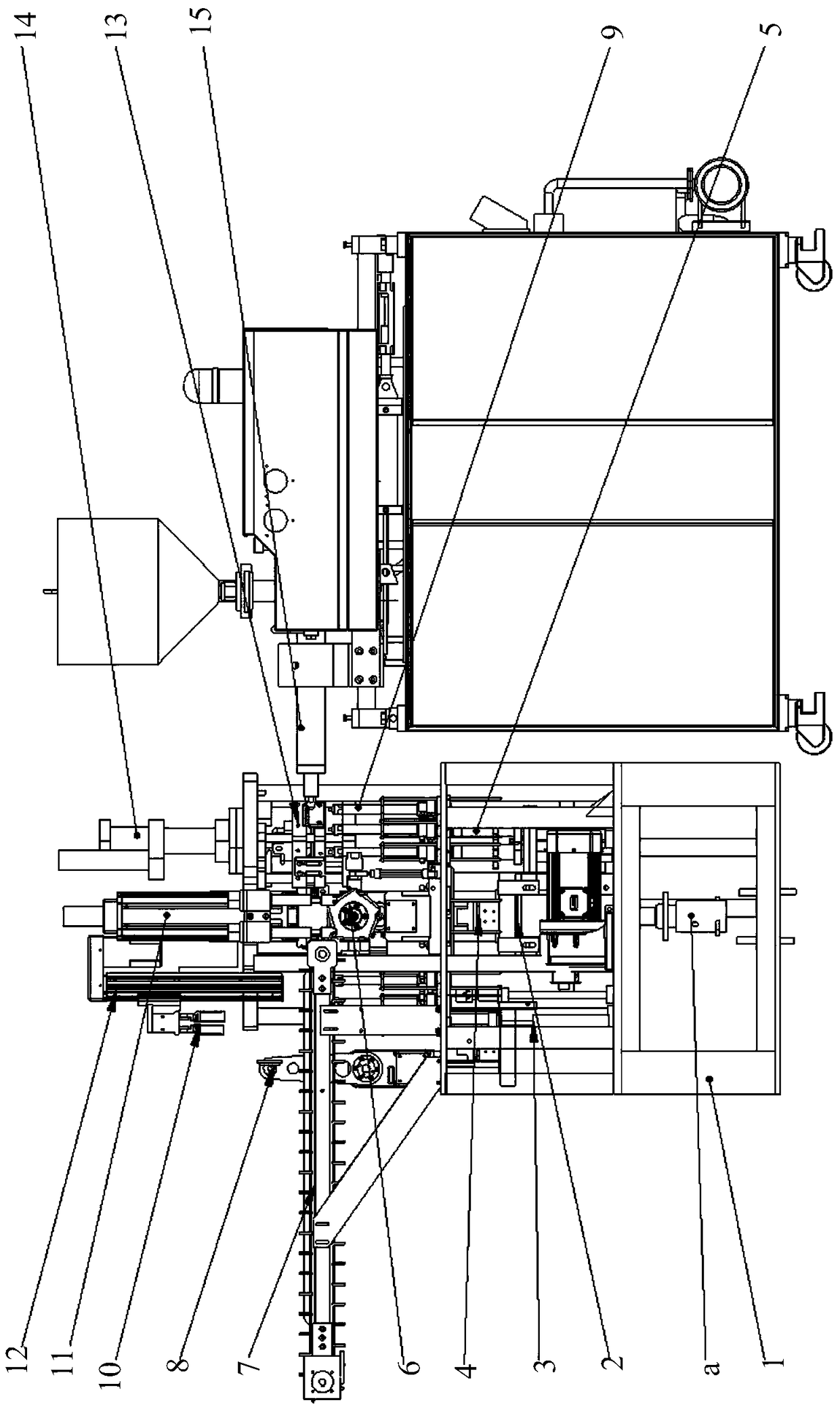

[0011] The upper shoulder bowl compression molding shoulder injection machine involved in the present invention will be described in detail below with reference to the accompanying drawings and embodiments.

[0012] figure 1 It is a structural schematic diagram of the upper shoulder bowl compression molding type shoulder injection machine in the embodiment of the present invention.

[0013] like figure 1 As shown, the upper shoulder bowl compression molding type shoulder injection machine has: frame 1, water cooling system, vacuum system, splitter 2, outlet pipe ejection cylinder 3, inlet pipe ventilation cylinder 4, support positioning mechanism 5, inlet pipe rotary Wheel 6, Conveyor belt 7, Manipulator for turning out pipe 8, Mandrel for lower mold 9, Manipulator for lifting out pipe 10, Mechanism for pressing down pipe 11, Mechanism for lifting out pipe 12, Upper mold 13, Gas-liquid pressurization Cylinder 14 and extruding plastic mechanism 15.

[0014] The frame 1 has a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com