A hydrogen storage material based on libh4 and its preparation method

A hydrogen storage material and ball milling technology are applied in the field of LiBH4-based hydrogen storage material and its preparation, which can solve the problems of expensive raw materials, lowering the hydrogen desorption temperature and high hydrogen desorption temperature of the hydrogen storage material, and achieve the effect of easy acquisition and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

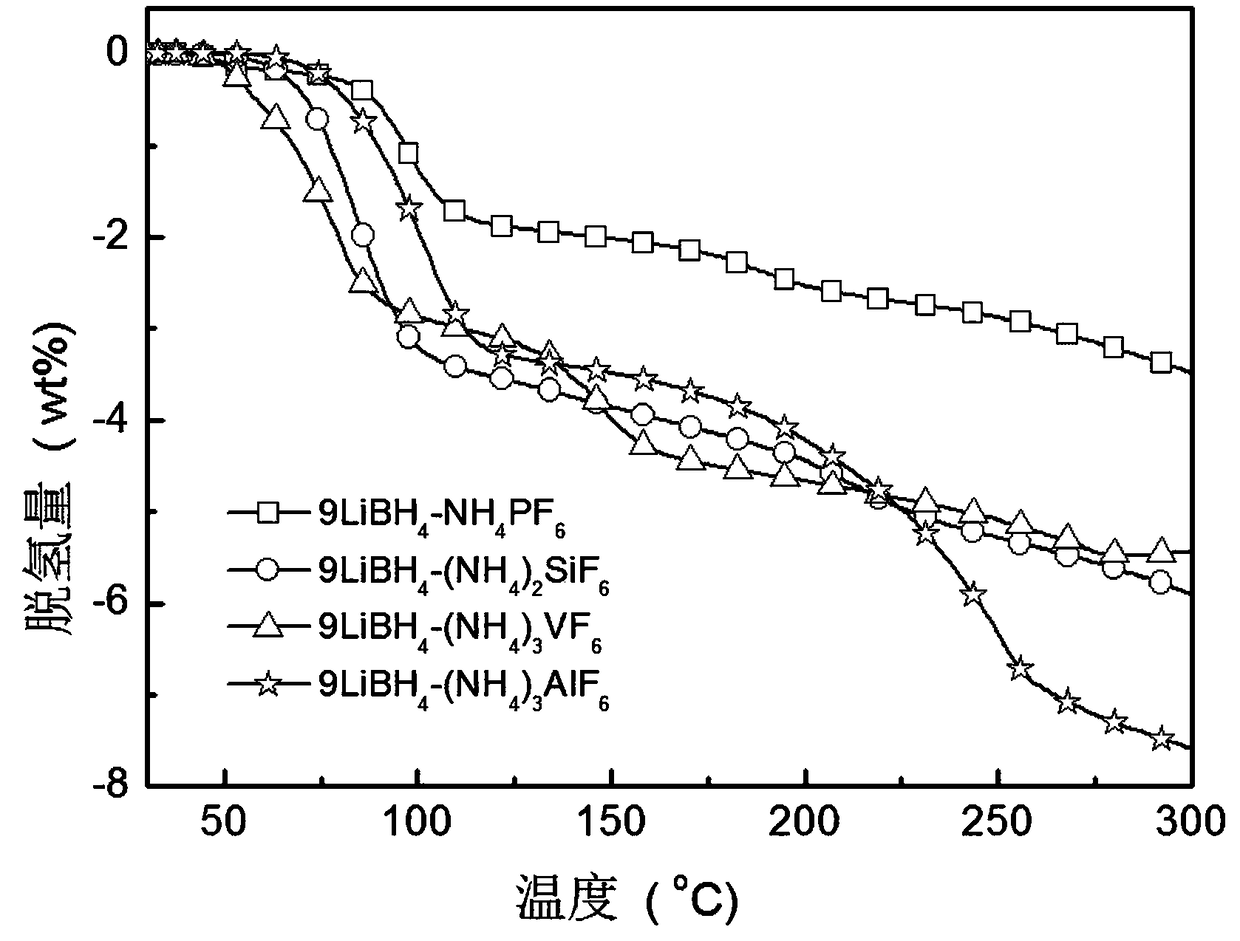

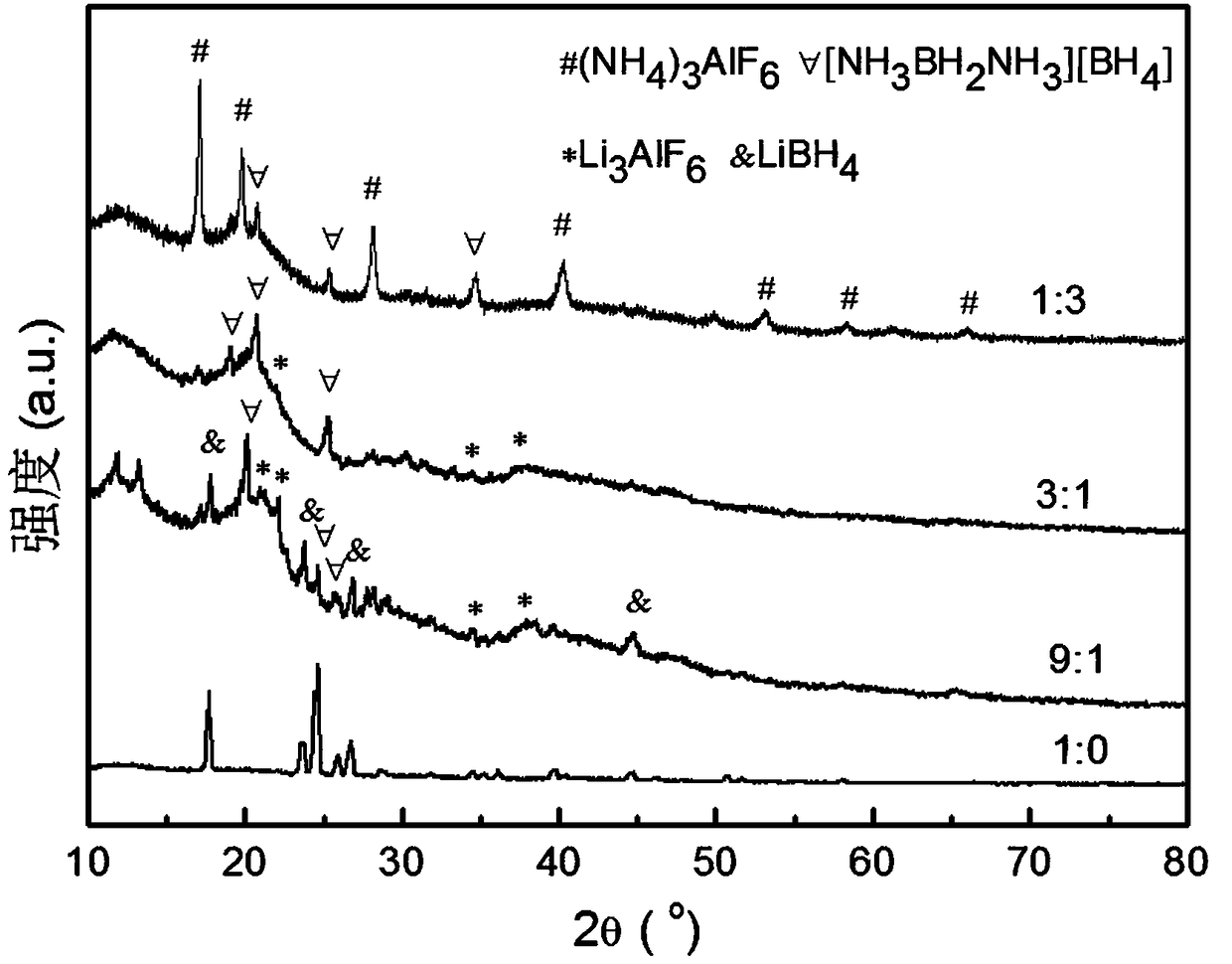

Embodiment 1

[0028] wxya 4 -NH 4 PF 6 Preparation of hydrogen storage materials:

[0029] (1) Take 0.2184 g of LiBH 4 and 0.1816 g of NH 4 PF 6 mixed as a sample for use;

[0030] (2) Put the sample into a ball mill jar with 20 steel balls with a diameter of 10 mm (80 g in weight) and seal it. The weight ratio of the balls to the sample is 200:1;

[0031] (3) Put the ball mill jar into the ball mill for ball milling, use the mechanical ball milling method to mix evenly, under the condition of inert gas, set the ball milling speed to 200 rpm, and the ball milling time to 2 h;

[0032] (4) After ball milling, take out the obtained product in the glove box to obtain 9LiBH 4 -NH 4 PF 6 Hydrogen storage material.

Embodiment 2

[0034] wxya 4 -(NH 4 ) 2 SiF 6 Preparation of hydrogen storage materials:

[0035] (1) Take 0.2096 g of LiBH 4 and 0.1904 g of (NH 4 ) 2 SiF 6 mixed as a sample for use;

[0036](2) Put the sample into a ball mill jar with 20 steel balls with a diameter of 10 mm and seal it. The weight ratio of the balls to the sample is 200:1;

[0037] (3) Put the ball mill jar into the ball mill for ball milling, use the mechanical ball milling method to mix evenly, under the condition of inert gas, set the ball milling speed to 200 rpm, and the ball milling time to 2 h;

[0038] (4) After ball milling, take out the obtained product in the glove box to obtain 9LiBH 4 -(NH 4 ) 2 SiF 6 .

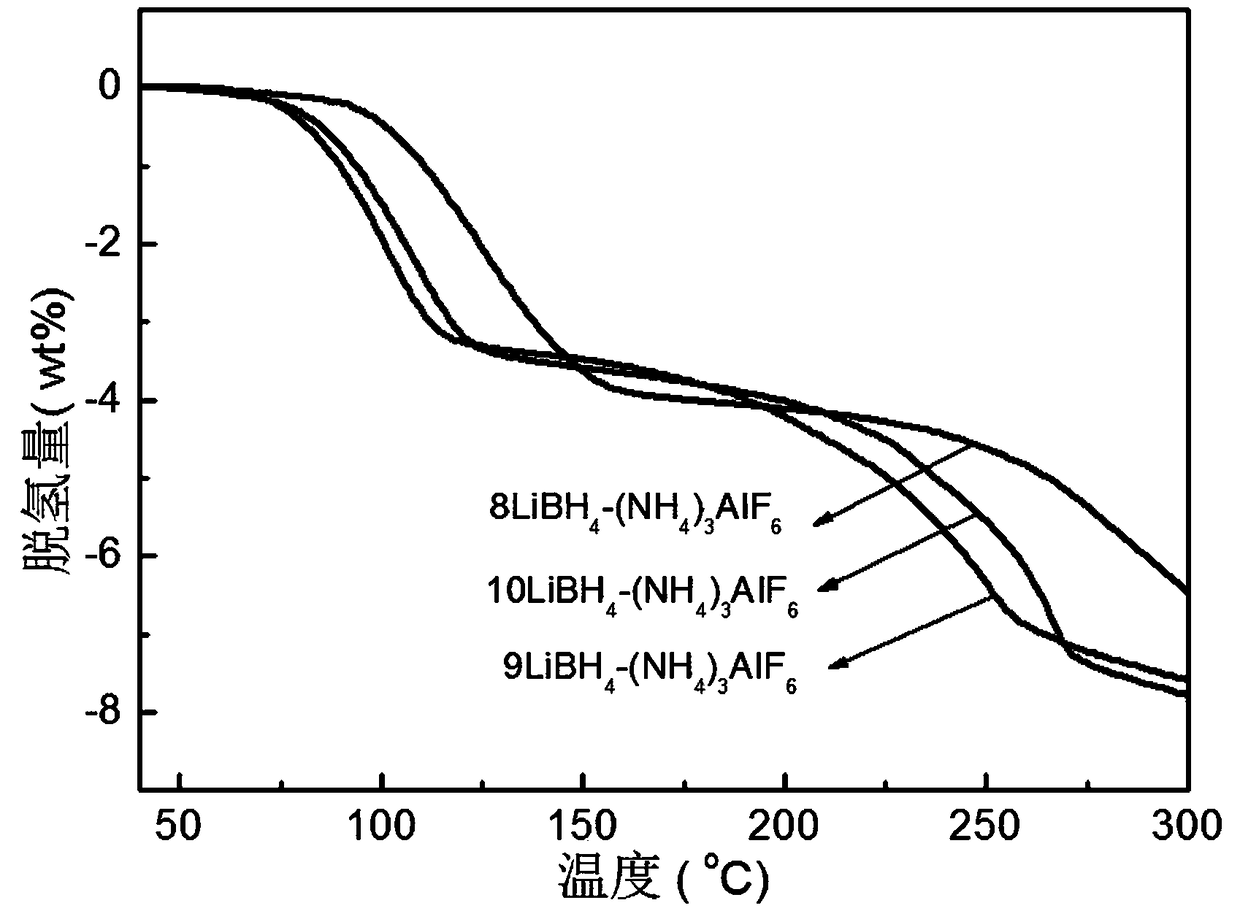

Embodiment 3

[0040] wxya 4 -(NH 4 ) 3 VF 6 Preparation of hydrogen storage materials.

[0041] (1) Take 0.1889 g of LiBH 4 and 0.2111 g of (NH 4 ) 3 VF 6 mixed as a sample for use;

[0042] (2) Put the sample into a ball mill jar with 20 steel balls with a diameter of 10 mm and seal it. The weight ratio of the balls to the sample is 200:1;

[0043] (3) Put the ball mill jar into the ball mill for ball milling, use the mechanical ball milling method to mix evenly, under the condition of inert gas, set the ball milling speed to 200 rpm, and the ball milling time to 2 h;

[0044] (4) After ball milling, take out the obtained product in the glove box to obtain 9LiBH 4 -(NH 4 ) 3 VF 6 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com