MgH2/Mg transition metal boride composite hydrogen storage material and preparation method thereof

A technology of transition metals and hydrogen storage materials, applied in the production of hydrogen, etc., to achieve safe storage and transportation, improve kinetic performance, and reduce hydrogen storage temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] MgH 2 Preparation and Kinetic Properties of +5wt%NiB Composite Hydrogen Storage Materials

[0026] In an anhydrous and oxygen-free glove box, magnesium hydride powder (purity 98%) and NiB were mixed according to MgH 2 The ratio of +5wt%NiB is mixed and added to the ball mill tank, put stainless steel balls, the weight ratio of the ball to material is 40:1, and seal; the ball mill tank is vacuumed, filled with argon and hydrogen for cleaning three times, and then filled with 2Mpa The high-purity hydrogen gas is milled for 1 hour by high-energy ball milling at a speed of 450 r / min to obtain the desired product.

[0027] Pure MgH was prepared under the same conditions 2 Compared with composite hydrogen storage materials.

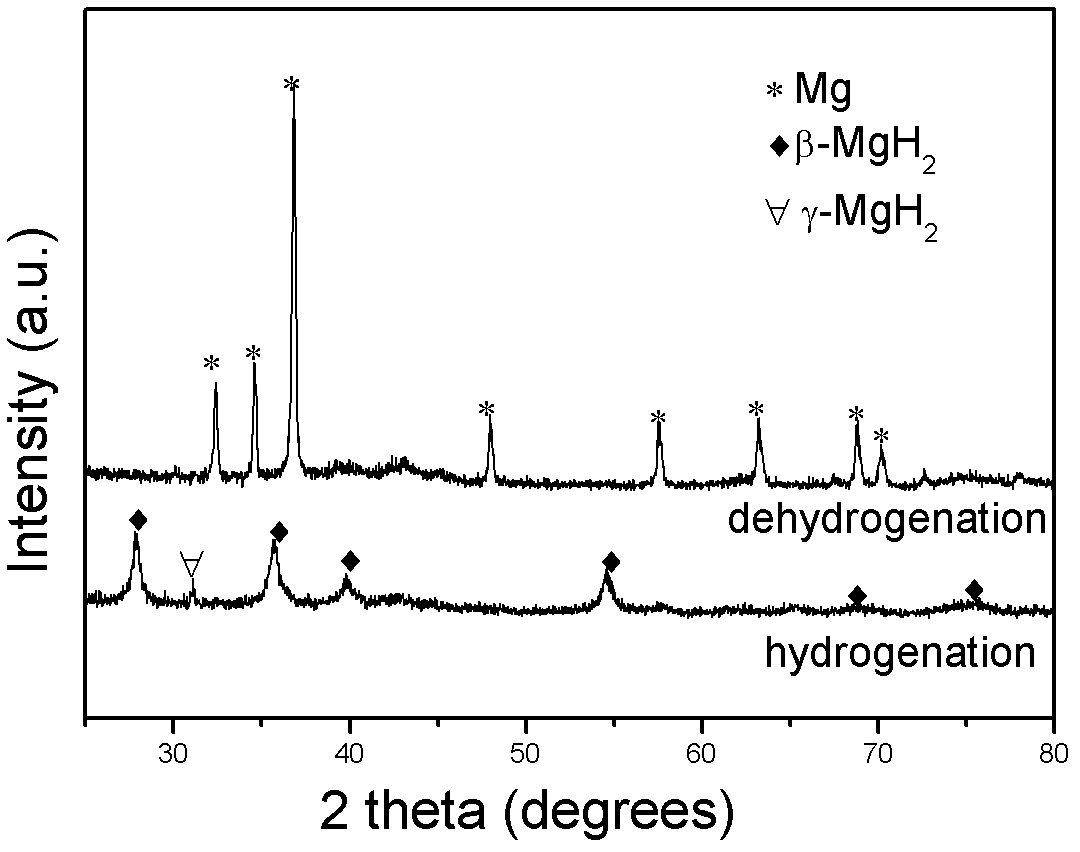

[0028] figure 1 MgH prepared for ball milling 2 The XRD pattern of +5wt%NiB before and after dehydrogenation, it can be seen from the XRD pattern that the sample after ball milling is mainly MgH 2 , while the sample after dehydrogenation is mainly ...

Embodiment 2

[0033] MgH 2 Preparation and Kinetic Properties of +15wt%NiB Composite Hydrogen Storage Material

[0034] In an anhydrous and oxygen-free glove box, magnesium hydride powder (purity 98%) and NiB were mixed according to MgH 2 The ratio of +15wt%NiB is mixed and added to the ball mill tank, put stainless steel balls, the weight ratio of the ball to material is 20:1, and seal; the ball mill tank is vacuumed, filled with argon and cleaned three times, and then filled with 0.1Mpa high-purity Argon, using high-energy ball milling at a speed of 200r / min for 15 hours to obtain the desired product. The prepared hydrogen storage alloy can release hydrogen at 450K, and 5.6wt% hydrogen can be released within 15 minutes at 573K.

Embodiment 3

[0036] MgH 2 Preparation and Kinetic Properties of +15wt%CoB Composite Hydrogen Storage Material

[0037] Magnesium hydride powder (purity 98%) and CoB according to MgH 2 The ratio of +15wt% CoB is mixed and added to the ball mill tank, put stainless steel balls, the weight ratio of the ball to material is 40:1, and seal; the ball mill tank is vacuumed and filled with argon and hydrogen for three times, and then filled with 0.1Mpa For high-purity hydrogen, the desired product is obtained after high-energy ball milling at a speed of 200r / min for 15 hours.

[0038] Figure 6 is MgH 2 The hydrogen desorption kinetic curves of +15wt% CoB at different temperatures and 0.01Mpa hydrogen pressure, it can be seen from the figure that at 503K, the composite hydrogen storage material can desorb 3.83wt% hydrogen within 80min. As the temperature increases, the hydrogen release rate also increases. At 573K, the amount of hydrogen released within 15min is 5.06wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com