Preparation method of premixed reinforced asphalt mixture

An asphalt mixture and enhanced technology, which is applied in the field of transportation engineering, can solve the problems such as damage to the road performance of asphalt mixture, complicated warm mixing technology and difficult evaluation of warm mixing effect, etc., so as to improve high temperature performance and avoid expensive additional agent, the effect of improving road performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0016] A preparation method for ready-mixed enhanced asphalt mixture, specifically comprising the following steps:

[0017] According to the ratio requirements of the project, first mix the aggregate and fiber evenly, then add soft asphalt and mix evenly, then add hard natural asphalt and mix evenly, and finally add mineral powder and mix evenly.

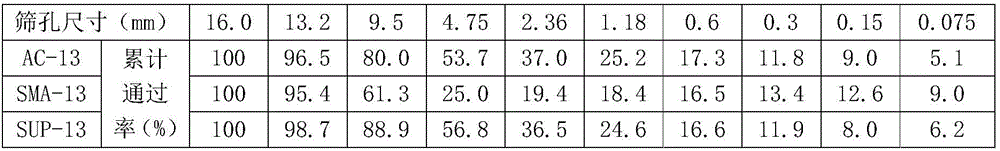

[0018] The aggregate is one or more of basalt, limestone and igneous rock.

[0019] The ore powder is limestone.

[0020] The fibers are lignin flocculent fibers, and the dosage is 0.1% to 0.3% of the mass of the aggregate.

[0021] Wherein the soft asphalt is Zhonghai 110 base asphalt.

[0022] The hard natural asphalt used is one of Trinidad Lake asphalt (code T), Qingchuanyan asphalt (code Q), and commonly used natural asphalt.

[0023] The aggregate and fiber mixing time is 10-15s.

[0024] Among them, the stirring time after adding the soft asphalt is 55-65s.

[0025] Among them, the mixing time after adding natural hard a...

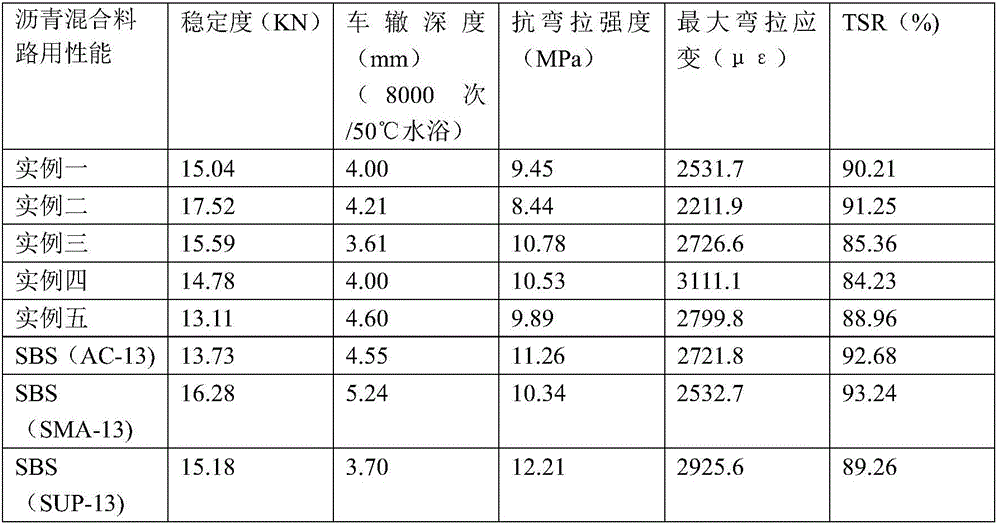

Embodiment 1

[0032] First, mix the aggregate AC-13 and fiber evenly, the fiber content is 0.1% of the aggregate mass, and the mixing time is 10s, then add Zhonghai 110# soft asphalt and mix evenly, the mixing time is 55s, and then add 25% The Trinidad Lake asphalt is mixed evenly, and the mixing time is 55s. Finally, mineral powder is added to mix evenly, and the mixing time is 45s.

example 2

[0034] A preparation method for ready-mixed-reinforced asphalt mixture, comprising the following steps:

[0035] First, mix the aggregate SMA-13 and fiber evenly, the fiber content is 0.2% of the aggregate mass, the mixing time is 11s, and then add Zhonghai 110# soft asphalt and mix evenly, the mixing time is 58s, and then add 25% The asphalt of Lake Trinidad was mixed evenly, and the mixing time was 58s. Finally, mineral powder was added and mixed evenly, and the mixing time was 48s. %.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com