Construction process of interlaced complex fiber modified asphalt concrete surface layer

A technology of composite fiber and modified asphalt, which is applied to cohesive pavement paved on site, roads, roads, etc., to achieve the effects of improving durability, increasing viscosity, and improving high-temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

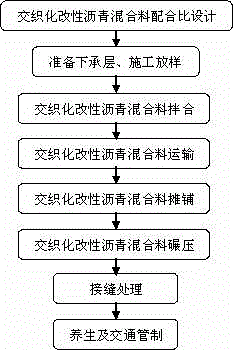

[0040] as attached figure 1 As shown, a construction process of interwoven composite fiber modified asphalt concrete surface, specifically includes the following steps:

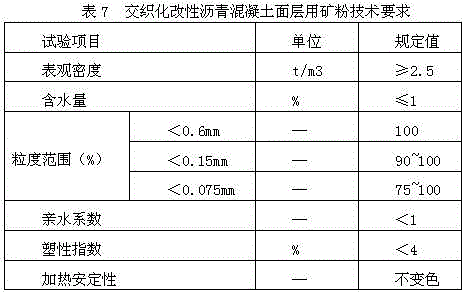

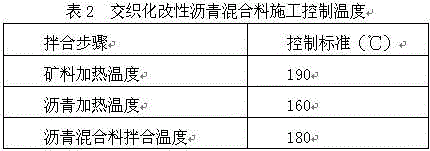

[0041] 1. Proportion design of interwoven modified asphalt mixture

[0042] The mix ratio design of interwoven modified asphalt mixture includes the target mix ratio design stage, the production mix ratio design stage and the production mix ratio verification stage. The amount of interwoven composite fiber is 0.3% of the total mass of asphalt mixture. In the process of mixing ratio design, the interwoven composite fiber is added in the "dry method" process. First, the interwoven composite fiber and aggregate are dry-mixed for 90 seconds to make them evenly dispersed in the mineral material, and then the matrix asphalt is added. Mix for 90s, finally add mineral powder, mix for 90s, and the total mixing time is 4.5min. The temperature control of the "dry" process during the test is shown in Table 1. The mine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com