A kind of flame retardant asphalt mixture and preparation method thereof

A technology of asphalt mixture and mixture, which is applied in the field of pavement asphalt materials, can solve the problems of accelerating asphalt pavement damage, etc., and achieve the effects of strengthening bonding ability, good anti-rutting ability, and increasing adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

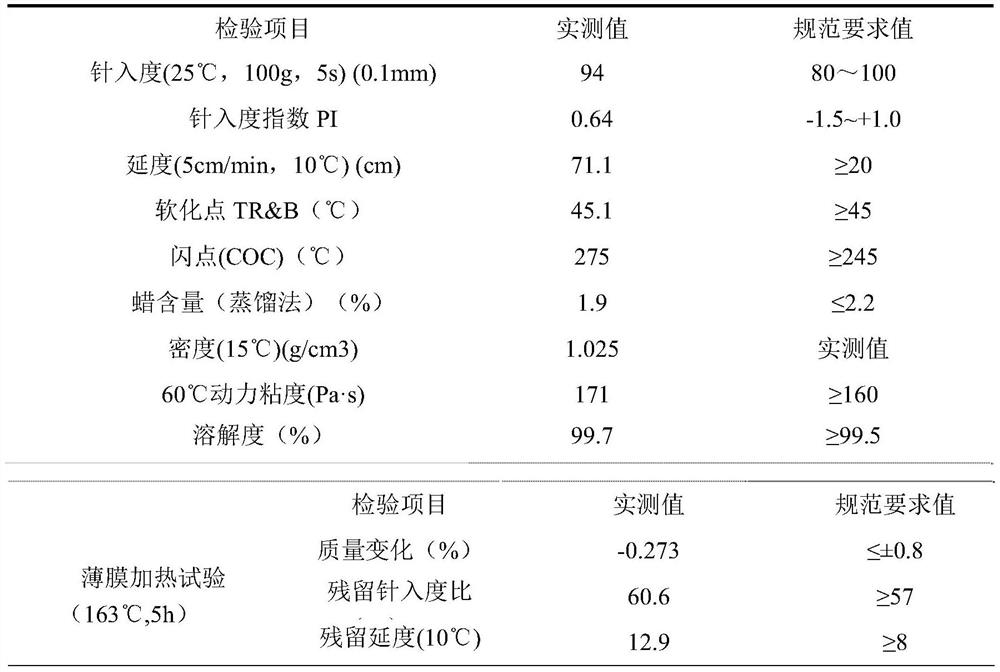

Embodiment 1

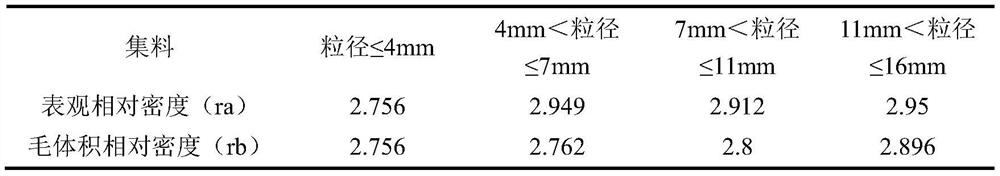

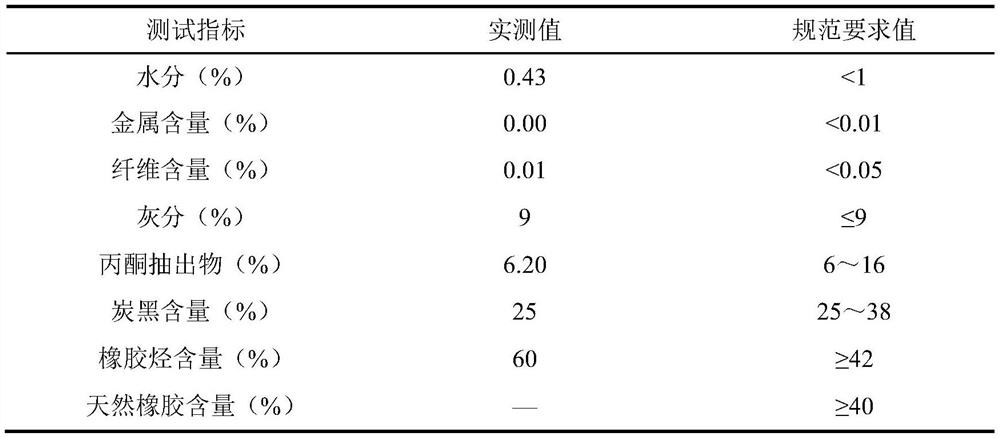

[0051] Weigh 15.86 parts by mass of 6mm polyimide fiber, 280 parts by mass of base asphalt, 880 parts by mass of diabase with particle size ≤ 4mm, 294 parts by mass of diabase with particle size ≤ 7mm, and 294 parts by mass with diabase with particle size ≤ 7mm, and diabase with particle size ≤ 7mm 1468 parts by mass of diabase of ≤11mm, 1957 parts by mass of diabase of 11mm<particle size≤16mm, 294 parts by mass of mineral powder, and 56 parts by mass of rubber powder.

[0052] Heat the base asphalt until the temperature reaches 160°C, slowly add rubber powder, and stir while heating. The rubber powder is added in three times on average, and the rubber powder is added in the previous time and stirred evenly before adding. The whole process of adding rubber powder takes about 5 minutes. Complete; after adding rubber powder, continue heating and stirring at 185°C for about 1.2h; then add diabase and weighed fibers together in the mixing pot and stir for 90s, and finally add miner...

Embodiment 2

[0054] Weigh 15.94 parts by mass of 3mm polyimide fiber, 310 parts by mass of base asphalt, 893 parts by mass of diabase with particle size ≤ 4mm, 298 parts by mass of diabase with particle size ≤ 7mm, and 298 parts by mass of diabase with particle size ≤ 7mm, and diabase with particle size ≤ 7mm 1489 parts by mass of diabase of ≤11mm, 1985 parts by mass of diabase of 11mm

[0055] The preparation steps are the same as in Example 1, and a flame-retardant asphalt mixture is prepared.

Embodiment 3

[0066] Weigh 11 parts by mass of 6mm polyimide fiber, 270 parts by mass of base asphalt, 860 parts by mass of diabase with a particle size of ≤4mm, 290 parts by mass of diabase with a particle size of 4mm

[0067] Heat the base asphalt until the temperature reaches 160°C, slowly add rubber powder, and stir while heating. The rubber powder is added in three times on average, and the rubber powder is added in the previous time and stirred evenly before adding. The whole process of adding rubber powder takes about 5 minutes. Complete; after adding rubber powder, continue heating and stirring at 180°C for about 1.5 hours; then add diabase and weighed fibers together in the mixing pot and stir for 90 seconds, and finall...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com