Preparation method of elastic complex

A kind of elastic composite body and technology of composite body, applied in the field of preparation of elastic composite body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

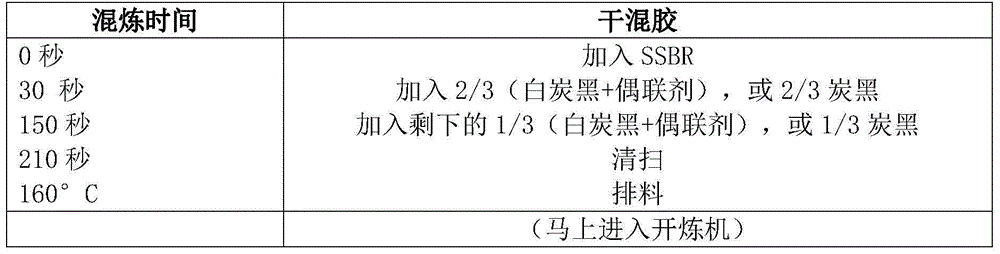

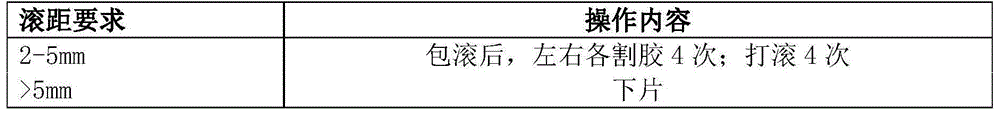

[0044] The present invention also provides a method for preparing the elastic composite, which is characterized in that it is prepared by a liquid-phase mixing and dispersing process, and the steps include: 1) making a modified white carbon black grinding slurry or carbon black in a non-polar organic solvent Grinding slurry; 2) Dispersing and mixing filler slurry or filler and rubber glue under high-energy shearing in proportion; 3) Dry removing the solvent from the uniformly dispersed composite slurry glue under dynamic conditions; 4) Removing The complex of solvents is sheared, kneaded and dried to obtain a product.

[0045] The solvent used in the filler slurry is non-polar organic solvents such as aliphatic hydrocarbons, alicyclic hydrocarbons, and aromatic hydrocarbons.

[0046] The solvent used in the rubber solution is non-polar organic solvents such as aliphatic hydrocarbons, alicyclic hydrocarbons, and aromatic hydrocarbons.

[0047] In step 1), if the filler is whit...

Embodiment 1

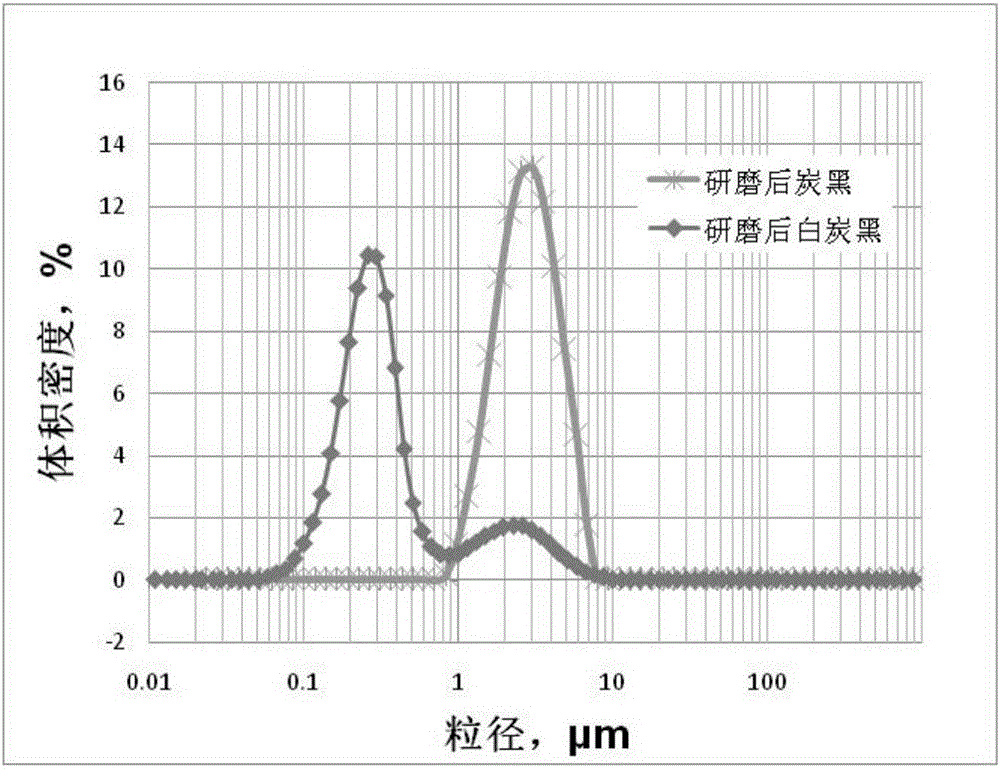

[0060] According to the preparation method of modified silica disclosed in patent application number 201410724713.2, a modified silica slurry with a silica aggregate particle size of 100nm-5μm was obtained, and the solid content was 5%wt.

[0061] In the high-energy disperser, 13.5kg of the above-mentioned modified white carbon black slurry is mixed with 6.8kg of concentration of 20%wt solution-polymerized styrene-butadiene rubber glue, wherein the ratio of the two solid contents is, rubber: white carbon black= 100:50. The high-energy disperser disperses the white carbon black evenly among the rubber molecules while grinding it to obtain a composite mixed liquid.

[0062] The composite mixed liquid is sent to the devolatilization extruder for solvent removal, and the temperature range of the eight blocks on the devolatilization extruder is set to 40-100°C, and the screw speed is 100 rpm. The compound mixed liquid is obtained through the extruder, and the volatile matter conte...

Embodiment 2

[0065] According to the preparation method of modified silica disclosed in patent application number 201410724713.2, a modified silica slurry with a silica aggregate particle size of 100nm-5μm was obtained, and the solid content was 10%wt.

[0066] In a high-energy disperser, mix 9kg of the above-mentioned modified silica slurry with 22.5kg of 5%wt solution-polymerized styrene-butadiene rubber glue, wherein the ratio of the two solid contents is, rubber: silica=100 :80. The high-energy disperser disperses the white carbon black evenly among the rubber molecules while grinding it to obtain a composite mixed liquid.

[0067] The composite mixed liquid is sent to the devolatilization extruder for solvent removal, and the temperature range of the eight blocks on the devolatilization extruder is set to 40-100°C, and the screw speed is 150 rpm. The compound mixed liquid is obtained through the extruder, and the volatile matter content is less than 1%.

[0068] The compound is knea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com