Tung oil extraction method

A technology of tung oil and tung tree, which is applied in the directions of fat oil/fat production, fat oil/fat refining, natural resource drying oil, etc. The effect of production, reducing labor intensity and saving labor resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

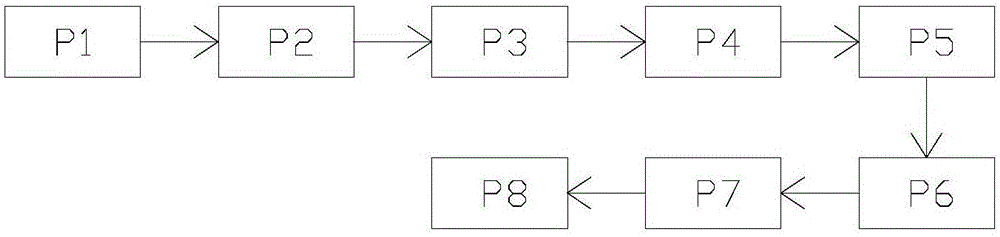

[0027] Such as Figures 1 to 5 Shown: in this preferred embodiment, tung oil refining method comprises the following steps:

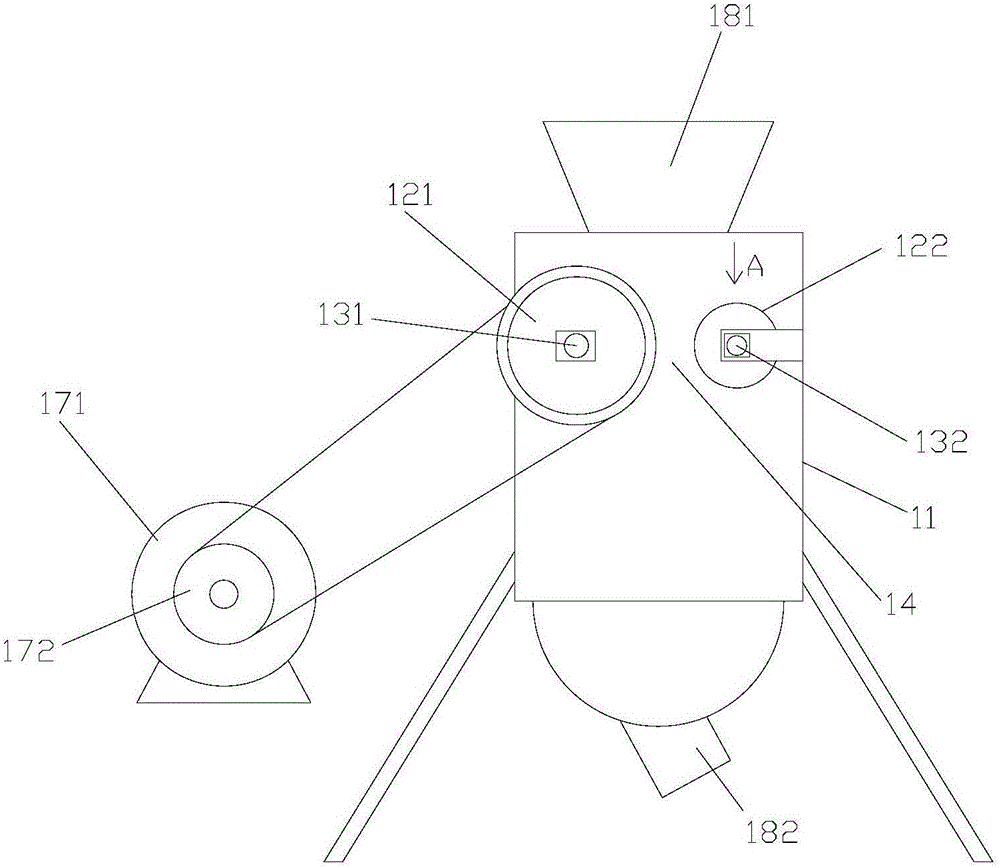

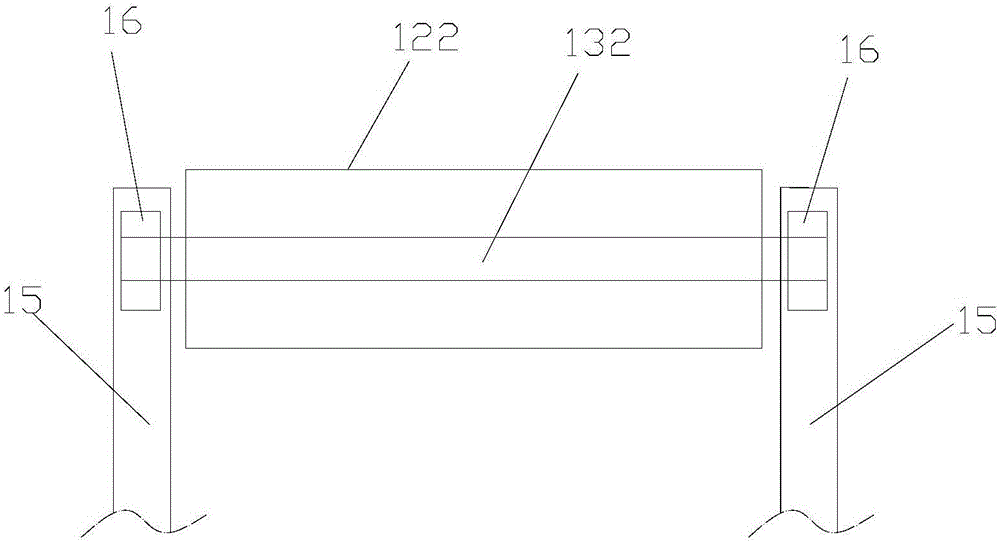

[0028] P1: put the tung tree green fruit into the seed remover to peel and remove the seeds; the seed remover includes a casing 1 and a seed removal mechanism arranged in the casing 1, and the casing 1 is provided with a feed inlet and an outlet The feed port, the seed removal mechanism includes a first roller 121, a second roller 122, a first rotating shaft 131 corresponding to the first roller 121 and a second rotating shaft 132 corresponding to the second roller 122, so The first roller 121 is driven to rotate by a power mechanism, and the first roller 121 is connected to the casing 1 through a mounting bracket; the first rotating shaft 131 is parallel to the second rotating shaft 132 and between the first roller 121 and the second rotating shaft A seed removal gap 14 is provided between the two rollers 122, and the green tung tree fruit enters the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com