Al-Ti-C intermediate alloy and preparation method thereof

A master alloy, al-ti-c technology, which is applied in the field of preparation of aluminum-based master alloys, can solve the problems of low purity, prone to agglomeration, and coarse TiC particle size, and achieves good metamorphic effect, meets demand, and moderate size. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

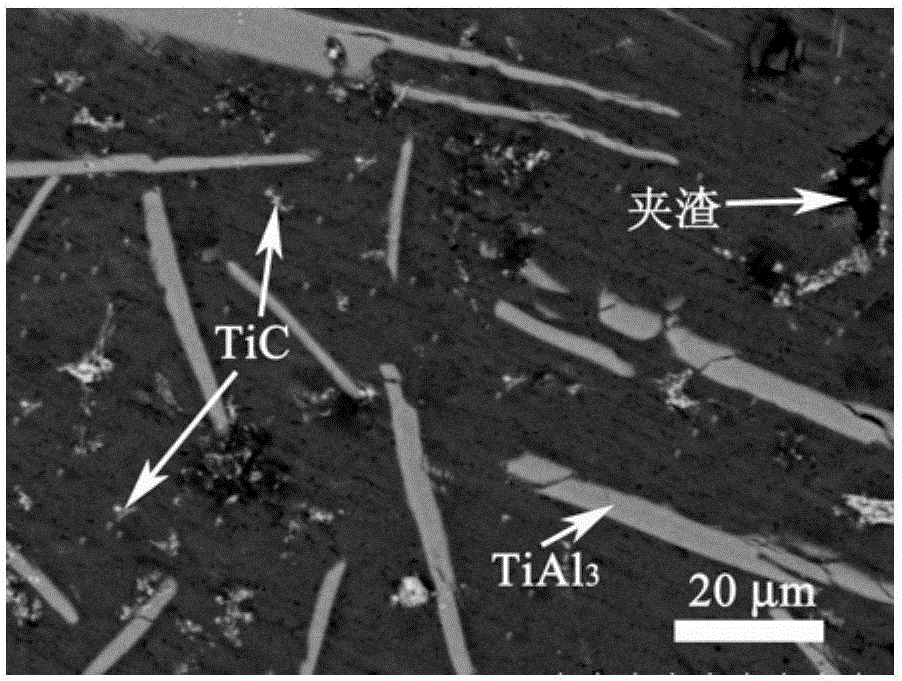

Image

Examples

Embodiment 1

[0028] The preparation process of the Al-Ti-C master alloy of this embodiment is as follows:

[0029] Put 2 kg of pure aluminum into a crucible and melt it in an intermediate frequency induction furnace; heat up to 1150-1250°C, mix 100 grams of potassium fluorotitanate and 6 grams of carbon nanotubes evenly and cover the surface of the aluminum melt, at 1150-1250°C Keep warm at 1250°C for 20-30 minutes, pour out the surface fluoride salt, stir the alloy melt, and pour it into a metal mold to form an Al-1.0%Ti-0.3%C master alloy ingot.

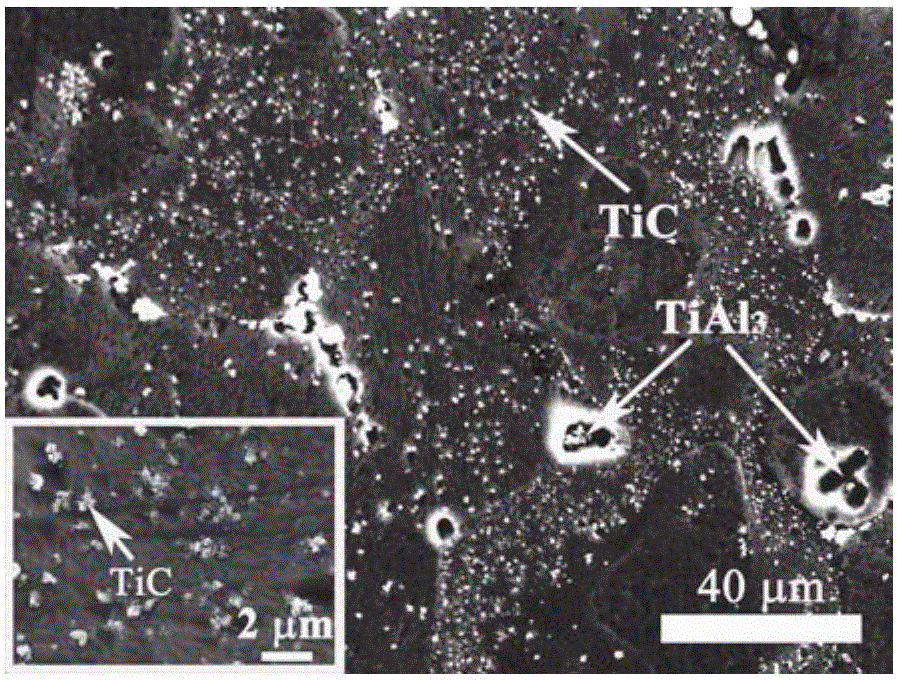

[0030] The composition of the prepared Al-Ti-C master alloy is Al-1.0%Ti-0.3%C (mass fraction), and its microstructure is as follows figure 2 As shown, it can be seen from the figure that TiC particles are dispersedly distributed in the Al-Ti-C master alloy, the TiC particle size is 50nm-2μm, and the TiC particle shape is spherical and / or nearly spherical.

[0031] Figure 5 (c) shows the refinement effect of the master alloy on industrial p...

Embodiment 2

[0033] The preparation process of the Al-Ti-C master alloy of this embodiment is as follows:

[0034] Put 2 kg of pure aluminum into a crucible and melt it in an intermediate frequency induction furnace; heat up to 1150-1250°C, mix 140 grams of potassium fluotitanate and 8 grams of carbon nanotubes evenly and cover the surface of the aluminum melt, Keep warm at 1250°C for 20-30 minutes, pour out the surface fluoride salt, stir the alloy melt, and pour it into a metal mold to form an Al-1.4%Ti-0.4%C master alloy ingot.

[0035] The composition of the prepared Al-Ti-C master alloy is Al-1.4%Ti-0.4%C (mass fraction), and its microstructure is as follows image 3 As shown, it can be seen from the figure that TiC particles are dispersedly distributed in the Al-Ti-C master alloy, the TiC particle size is 60nm-2.5μm, and the TiC particle shape is spherical and / or nearly spherical.

[0036] Figure 5 (d) shows the refinement effect of the master alloy on industrial pure aluminum, co...

Embodiment 3

[0038] The preparation process of the Al-Ti-C master alloy of this embodiment is as follows:

[0039] Put 2 kg of pure aluminum into a crucible and melt it in an intermediate frequency induction furnace; heat up to 1150-1250 ° C, mix 420 grams of potassium fluorotitanate and 24 grams of carbon nanotubes evenly and cover the surface of the aluminum melt. Keep warm at 1250°C for 20-30 minutes, pour out the fluoride salt on the surface, stir the alloy melt, and pour it into a metal mold to form an Al-4.2%Ti-1.2%C master alloy ingot.

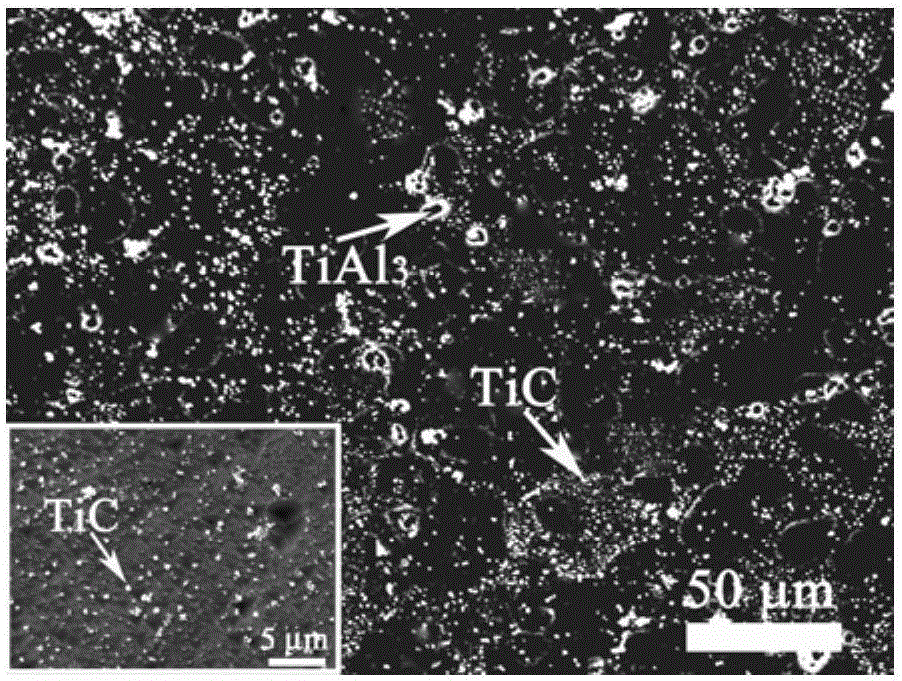

[0040] The composition of the prepared Al-Ti-C master alloy is Al-4.2%Ti-1.2%C (mass fraction), and its microstructure is as follows Figure 4 It can be seen from the figure that the TiC particles are dispersedly distributed in the Al-Ti-C master alloy, the TiC particle size is 60nm-3μm, and the TiC particle shape is spherical and / or nearly spherical.

[0041] Figure 5 (e) shows the refinement effect of the master alloy on industrial pure aluminu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com