Modular assembling vertical circulation stereo garage frame body

A vertical circulation, three-dimensional garage technology, applied in the field of garage accessories, can solve the problems of increasing the number of parkable cars, the height of the frame body is high, and cannot be changed, and achieves simple manufacturing and assembly processes, low manufacturing costs, and manufacturing difficulties. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

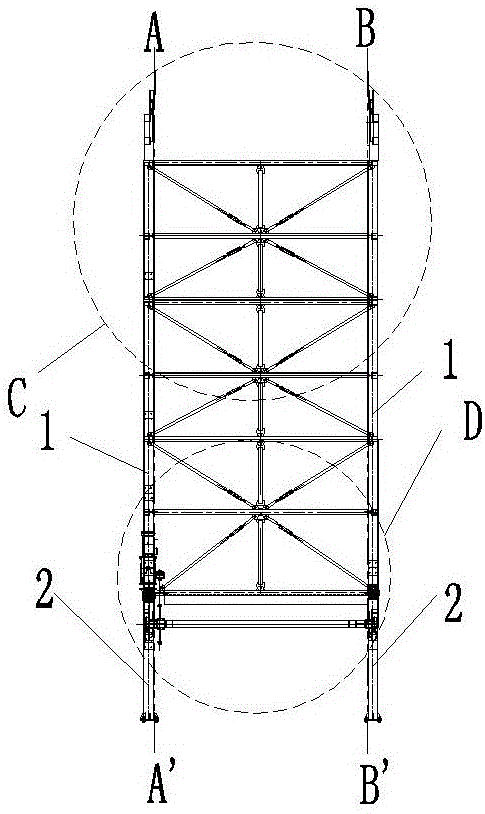

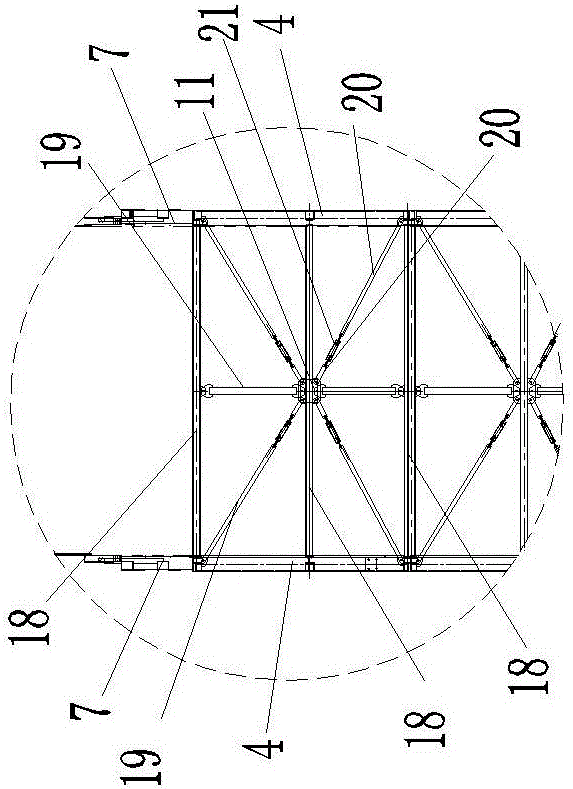

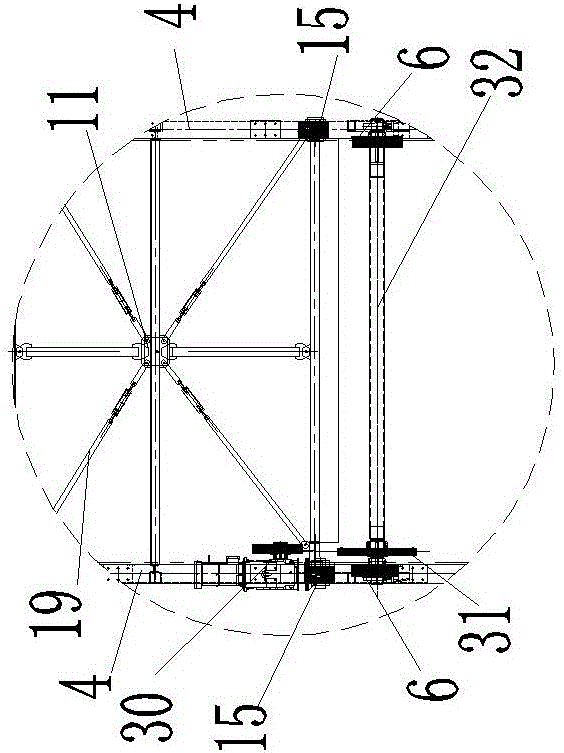

[0062] Example 1. Such as Figure 17-28 As shown, a modularly assembled vertical circulation three-dimensional garage frame body includes two module combinations 1 arranged symmetrically and connected together by horizontal connectors. Each module combination 1 is installed on a base; each module combination consists of Several shelf modules are formed in series on the top and bottom in turn, and adjacent shelf modules are connected by two detachable connecting devices 15.

[0063] Among the facing shelf modules, the two sides of the butting end of the upper shelf module are respectively connected to the left and right sides of the butting end of the shelf module below by a detachable connecting device 15.

[0064] The detachable connecting device 15 includes a pair of connecting components with the same structure, a positioning bolt 154, and two connecting bolts 155; the connecting components are respectively located on the butting sides of the butting ends of the two frame module...

Embodiment 2

[0078] Example 2. The difference between this embodiment and the first embodiment is that the connecting component is an integral part made by forging or casting. The connecting components made of forging or casting are integral structure with good connecting effect. The frame modules that make up the frame of the vertical circulation three-dimensional garage frame are small in size, convenient for transportation and hoisting, and can be quickly assembled on the construction site; the combined structure is adopted, and the larger and other components are relatively simple in production and assembly processes. Manufacturing difficulty and manufacturing cost are also relatively low; the connecting device is detachable, and the height of the vertical circulation three-dimensional garage frame can be easily adjusted by increasing the number of frame modules to adjust the height of the three-dimensional garage and increase the number of parking cars , It is convenient to transform ...

Embodiment 3

[0079] Example 3. The difference between this embodiment and the first embodiment is: the top module 7, the upper frame modules 4 of the two frame modules 4 are connected by a detachable connecting device 15, and the two frame modules 4 are connected to the lower frame of the two frame modules 4 Welding connection between module 4 and bottom module 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com