Anti-looseness bolt assembly for high-radioactivity equipment and expanding type anti-looseness process

An anti-loosening bolt, high radioactive technology, applied in bolts, mechanical equipment, threaded fasteners, etc., can solve problems such as the inability to use anti-loosening bolts to repair, the failure of the bolt anti-loosening structure, and the potential safety hazards of equipment and systems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

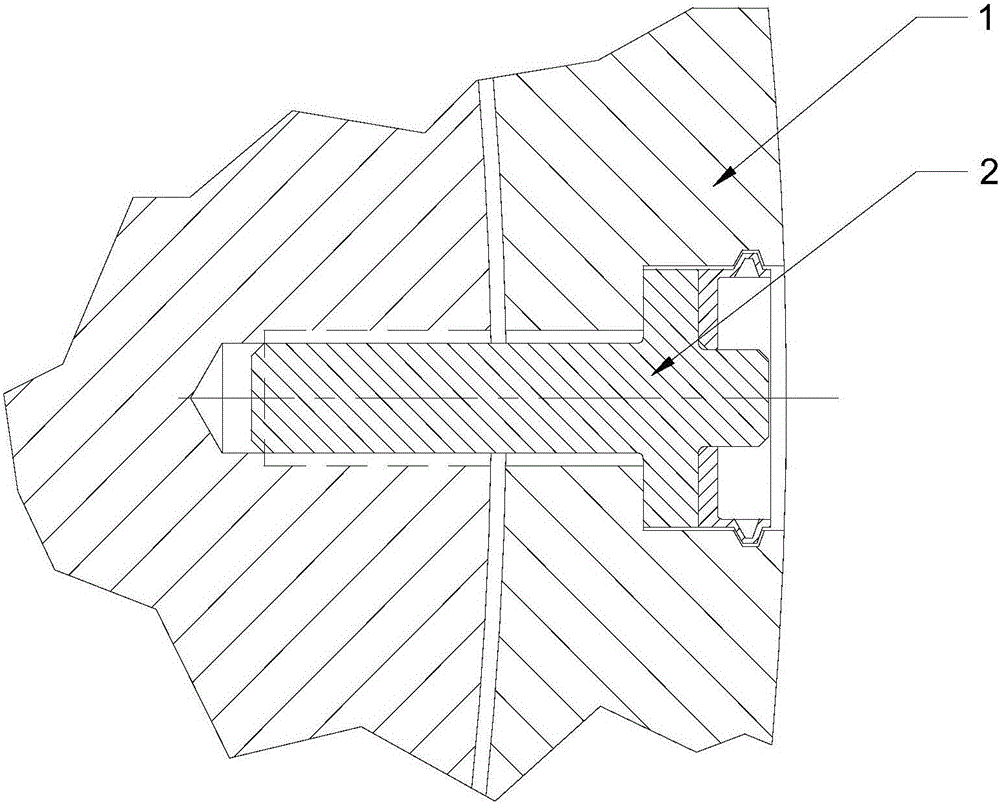

[0086] The device structure involved in the present invention will be described in detail below in conjunction with the drawings and specific embodiments.

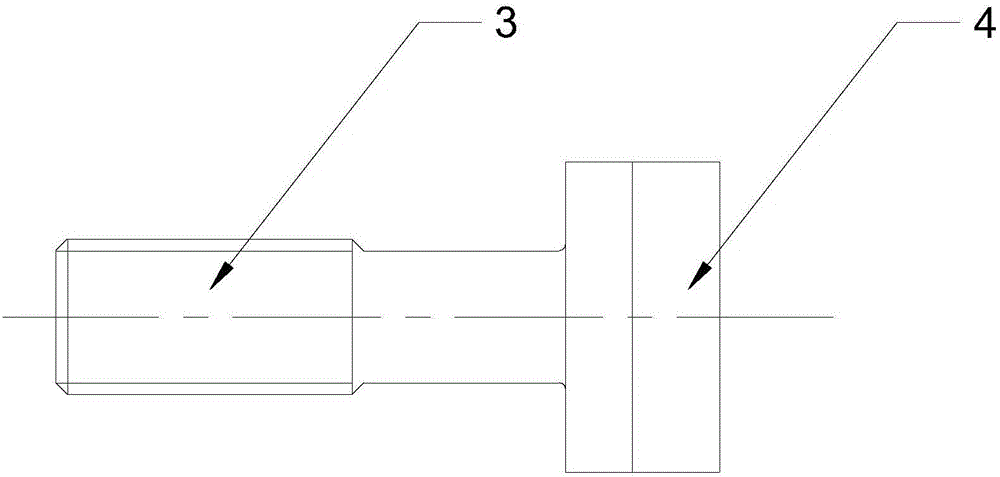

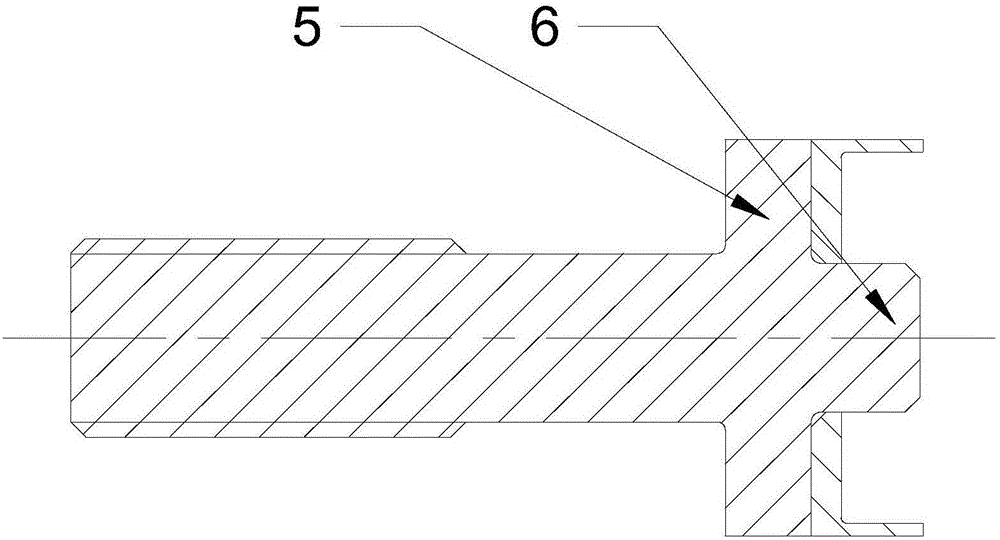

[0087] Such as figure 2 As shown, the anti-loosening bolt assembly 2 of the present invention is assembled by the anti-loosening bolt A3 and the anti-loosening cap 4. After the assembly, the anti-loosening cap 4 will rotate together with the anti-loosening bolt A3 when the anti-loosening bolt A3 rotates. The thread size and thread length of the A3 threaded part of the anti-loosening bolt are the same as the thread design on the original equipment. The upper part of the anti-loosening bolt A3 is a circular boss gasket 5. The main function of the boss gasket 5 is to flatten and compact the joint surface between the bolt and the processed body 1 of the high-radioactive equipment after the bolt is installed, and at the same time as an anti-loosening device. Locating platform for Matsumoto 4. The upper end of the circular bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com