Chain-grate boiler pulverized coal conveying pipeline provided with secondary pressure stabilizing system

A pulverized coal transportation and chain boiler technology, which is applied in the field of coal-fired boilers, can solve problems such as pressure fluctuations, blockage of pipes, and influence on the uniformity of chain boiler combustion, and achieve the effect of reducing pressure fluctuations and improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

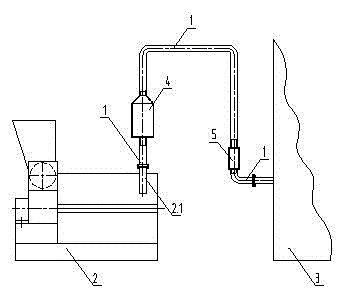

[0012] The chain boiler pulverized coal conveying pipeline provided with the secondary voltage stabilizing system shown in the accompanying drawing is arranged between the pulverized coal grinder 2 and the chain boiler 3, including the pulverized coal conveying pipeline 1; in the pulverized coal conveying pipeline 1 Install the buffer cylinder I4 and buffer cylinder II5 in series; the buffer cylinder I4 is set in the pulverized coal conveying pipeline 1 connected with the coal powder output pipe 2.1 of the pulverized coal grinder 2, and the buffer cylinder II5 is set between the buffer cylinder I4 and the chain boiler In the pulverized coal conveying pipeline 1 between 3; the cross-sectional area of the buffer cylinder I4 is 2 to 8 times that of the pulverized coal conveying pipeline 1, and the cross-sectional area of the buffer cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com