Semiconductor component image test device and its test equipment

A technology of testing equipment and testing equipment, which is applied in the direction of semiconductor/solid-state device testing/measurement, measuring equipment, instruments, etc., and can solve problems such as inability to achieve high-speed transmission frequency, inability to meet high-efficiency semiconductor component test specifications, narrow bandwidth, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The above summary and the following detailed description are exemplary in order to further illustrate the scope of the present invention. Other purposes and advantages of the present invention will be described in the subsequent description and illustrations.

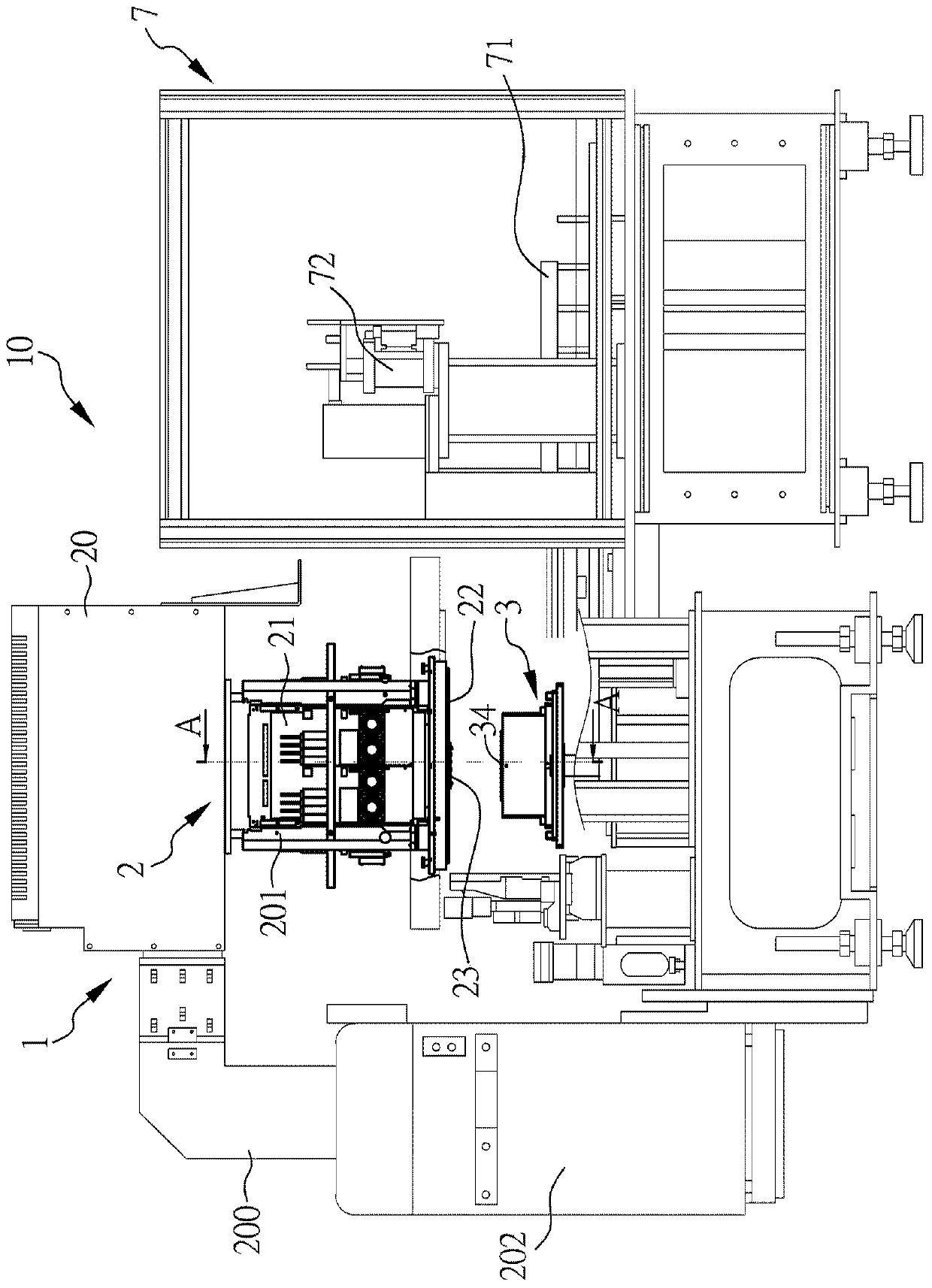

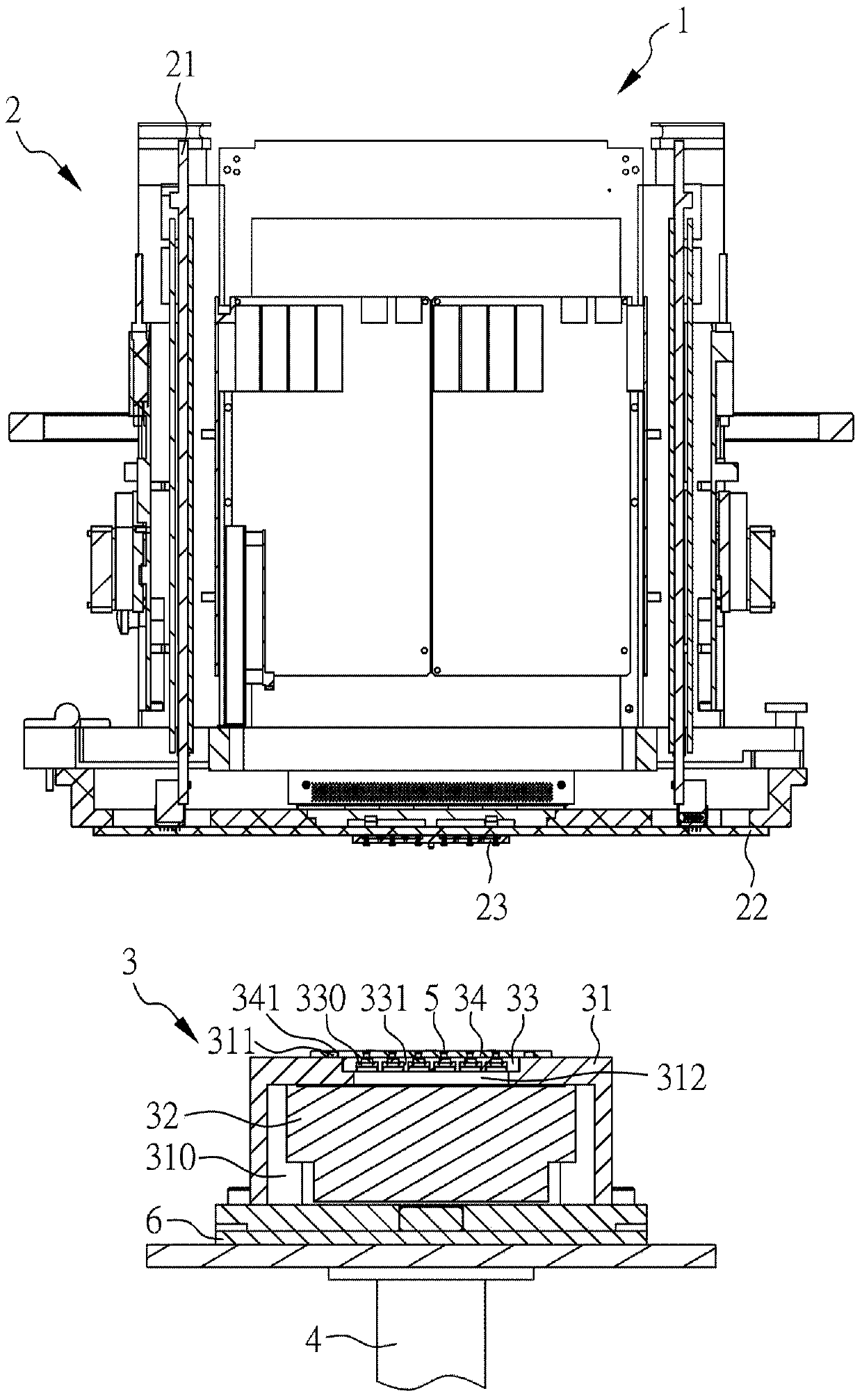

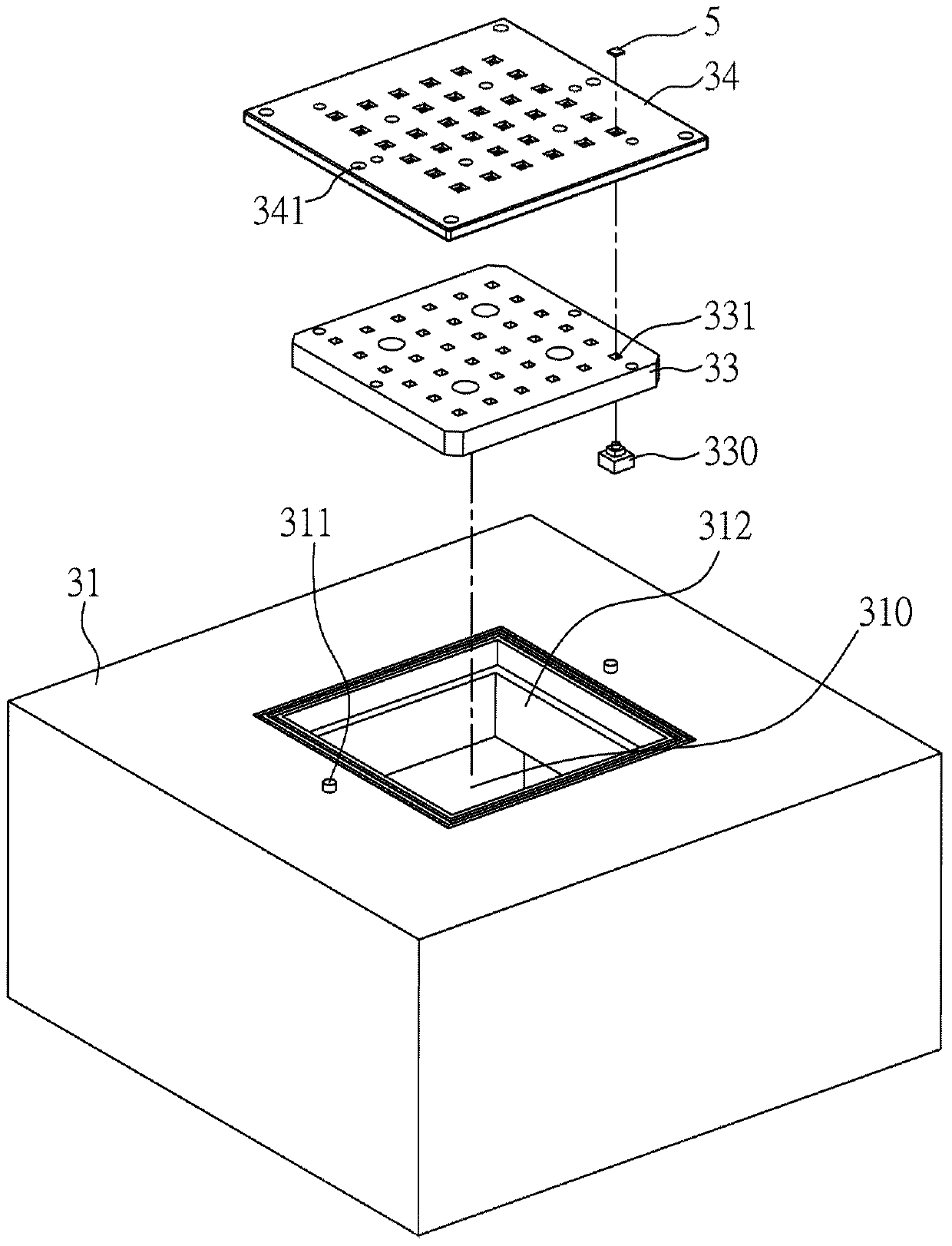

[0035] see figure 1 , is a side view of a semiconductor device image testing device according to a preferred embodiment of the present invention. The figure shows a semiconductor element image test equipment 10, which includes a semiconductor element image test device 1 and a sorting machine 7, wherein the semiconductor element image test device 1 further includes a test circuit module 2 and a mobile light source module 3. In this embodiment, the above-mentioned test circuit module 2, a mobile light source module 3, and the sorting machine 7 have a separate structure, so under the same test structure, it is possible to fine-tune some modules and test other final test logic products to achieve Image test shares...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com