Electro-optic Arbitrary Waveform Generator Based on Graphene Grating Microfiber

An arbitrary waveform and graphene technology, applied in instruments, optics, nonlinear optics, etc., can solve problems such as difficult to manufacture and expensive, and achieve the effect of low transmission loss and easy manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

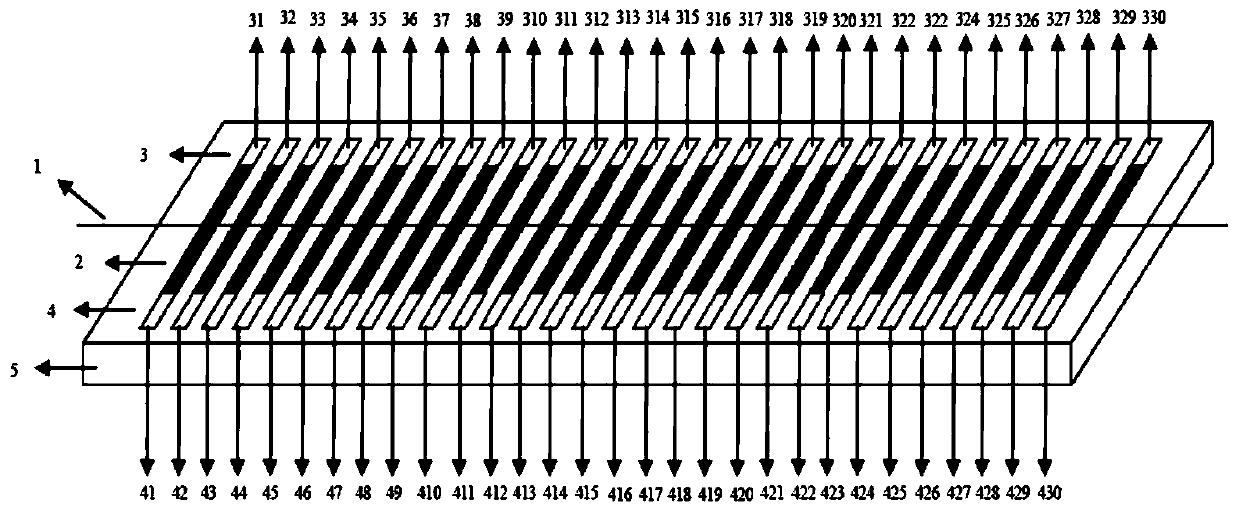

[0086] The arbitrary waveform generator includes a microfiber 1, a graphene grid layer 2, a positive electrode array 3 (positive electrodes 31, 32, 33, 34, 35, 36, 37, 38, 39, 310, 311, 312, 313, 315 , 316, 317, 318, 319, 320, 321, 322, 323, 324, 325, 326, 327, 328, 329, 330), negative electrode array 4 (negative electrode 41, 42, 43, 44, 45, 46 , 47, 48, 49, 410, 411, 412, 413, 414, 415, 416, 417, 418, 419, 420, 421, 422, 423, 424, 425, 426, 427, 428, 429, 430), Flat base 5( figure 1 ). The combination method is as follows: the graphene grid layer 2 is placed on the flat substrate 5, and the microfiber 1 is placed on the graphene grid layer 2. The diameter of the fine optical fiber 1 is 8 μm, the unit length of the graphene grid layer 2 is 300 μm, the distance between adjacent units is 280 μm, the number of units is 30, and the size of the entire flat substrate 5 is 18 mm×1 mm. The number of graphene gate layer 2 used is 1. The carrier wave is introduced from one end of t...

Embodiment 2

[0088] The arbitrary waveform generator includes a microfiber 1, a graphene grid layer 2, a positive electrode array 3 (positive electrodes 31, 32, 33, 34, 35, 36, 37, 38, 39, 310, 311, 312, 313, 315 , 316, 317, 318, 319, 320, 321, 322, 323, 324, 325, 326, 327, 328, 329, 330), negative electrode array 4 (negative electrode 41, 42, 43, 44, 45, 46 , 47, 48, 49, 410, 411, 412, 413, 414, 415, 416, 417, 418, 419, 420, 421, 422, 423, 424, 425, 426, 427, 428, 429, 430), Flat base 5( figure 1 ). The combination method is as follows: the graphene grid layer 2 is placed on the flat substrate 5, and the microfiber 1 is placed on the graphene grid layer 2. The diameter of the fine optical fiber 1 is 5 μm, the unit length of the graphene grid layer 2 is 120 μm, the distance between adjacent units is 110 μm, the number of units is 30, and the size of the entire flat substrate 5 is 7 mm×1 mm. The number of graphene gate layers 2 used is four. The carrier wave is introduced from one end o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com