Four-phase seepage simulation method for movable gel system

A simulation method and gel technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as the inability to fully reflect the characteristics of underground seepage and disconnection of movable gel systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

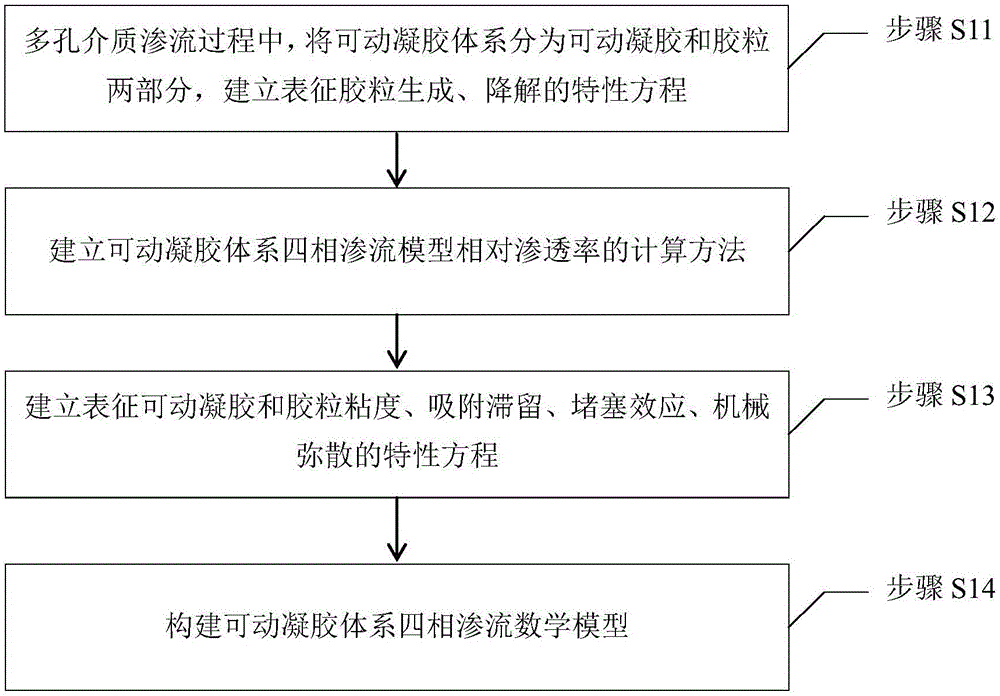

[0134] This example provides a four-phase seepage simulation method for a movable gel system, which divides the movable gel system into two parts, the movable gel and the colloidal particles, and establishes a four-phase seepage model for the movable gel system, On this basis, the four-phase seepage mathematical model of oil phase, gas phase, water phase and colloidal particles is constructed, and the specific steps ( figure 1 It is a schematic flow chart of the method) including:

[0135] Step S11, during the seepage process of the porous medium, the movable gel system is divided into two parts, the movable gel and the colloidal particles, and a characteristic equation characterizing the generation and degradation of the colloidal particles is established;

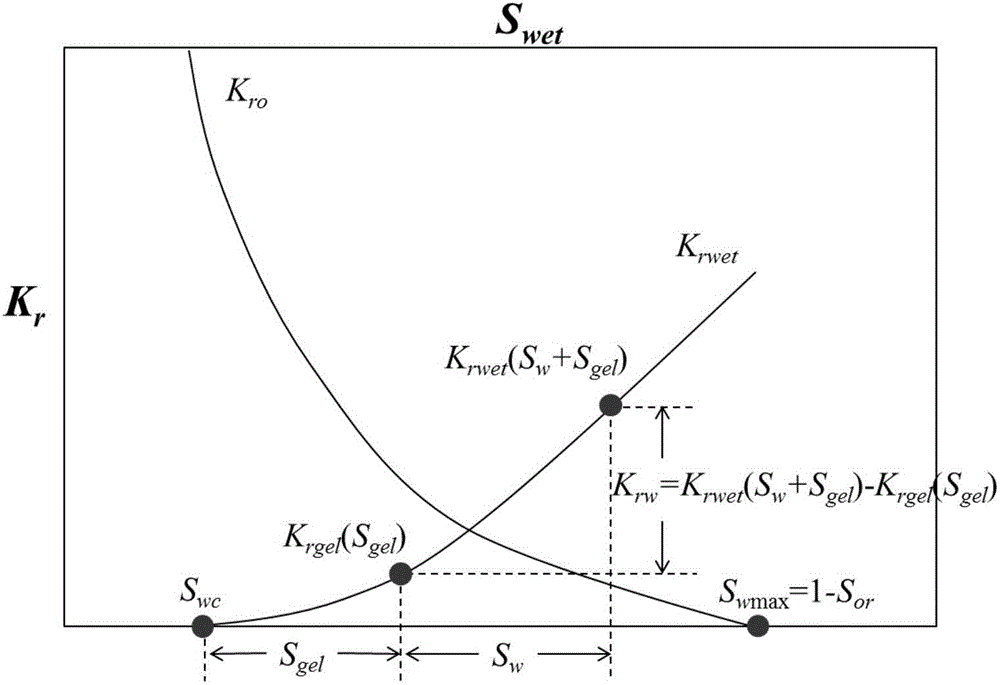

[0136] Step S12, establishing a calculation method for the relative permeability of the four-phase seepage model of the movable gel system;

[0137] Step S13, establishing characteristic equations characterizing the visc...

Embodiment 2

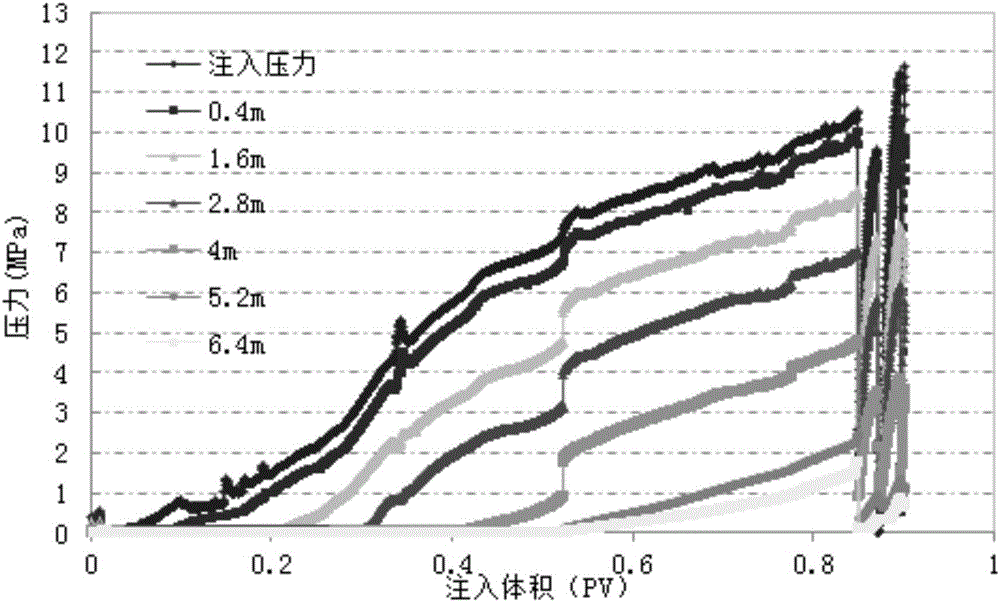

[0269] This example provides a verification experiment for implementing a four-phase seepage simulation method for a movable gel system.

[0270] In order to have a more intuitive understanding of the application effect of a four-phase seepage simulation method for a movable gel system provided in Example 1, the calculation program compiled using the above method is now used to simulate the displacement experiment of the movable gel in the sand-packing pipe. The fitting result shows that the present invention can simulate the actual seepage process of the movable gel system with high accuracy.

[0271] In this embodiment, the experimental parameters of the sand filling pipe are shown in Table 1; the specifications of the sand filling pipe are shown in Table 2.

[0272] In this example, the measured pressure curve of the displacement experiment of the movable gel system in the sand filling pipe is as follows: image 3 shown; the pressure curve fitted by the displacement experi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com