Capacitor embedding tool

A capacitor and potting technology, which is applied in the direction of capacitors, packaged capacitor devices, capacitor manufacturing, etc., can solve the problems of affecting the appearance quality of capacitors, occupying a lot of labor, and difficult manual control, etc., so as to improve potting efficiency, facilitate operation, and save materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

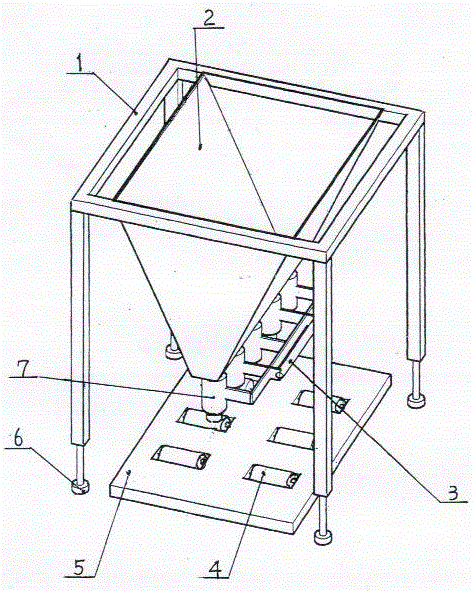

[0009] Examples, see attached figure 1 , the lower ends of the four pillars of the capacitor potting tooling support 1 are respectively equipped with adjustable feet 6, and the potting material barrel 2 is fixed in the support 1, and five valves 7 are evenly arranged under the bottom of the potting material barrel 2, The valves 7 are respectively connected with the potting material barrel 2, the bottom of the five valves 7 is connected with a main valve 3, the bottom of the bracket 1 is equipped with a chassis 5 in the middle of the four adjustable feet 6, and the bottom of the chassis 5 is equipped with six ground rollers 4 .

[0010] The method of using the capacitor potting tool is as follows: first, adjust the level of the capacitor potting tool through the adjustable foot 6, and cover the capacitor lead-out terminal positioning fixture on the capacitor bank to be potted, and the capacitor bank to be potted together with the capacitor The lead terminal positioning fixture...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com