Display device and method for preparing organic light emitting diode display panel

A technology of light-emitting diodes and display panels, applied in semiconductor/solid-state device manufacturing, electric solid-state devices, semiconductor devices, etc., can solve the problem of performance degradation of display devices, insufficient distribution of conductive particles 131, and reduced contact performance between pads 12 and FPC film 14 And other problems, to avoid short circuit, improve the effect of contact performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

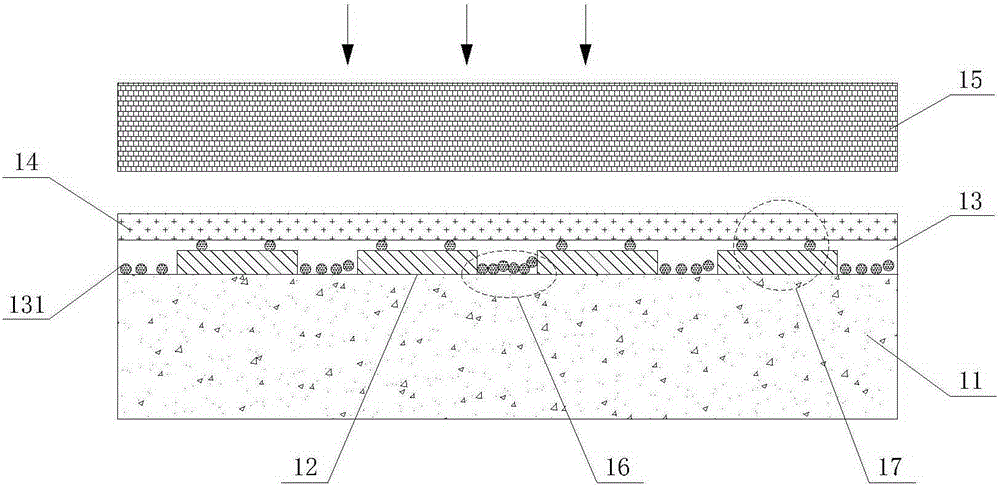

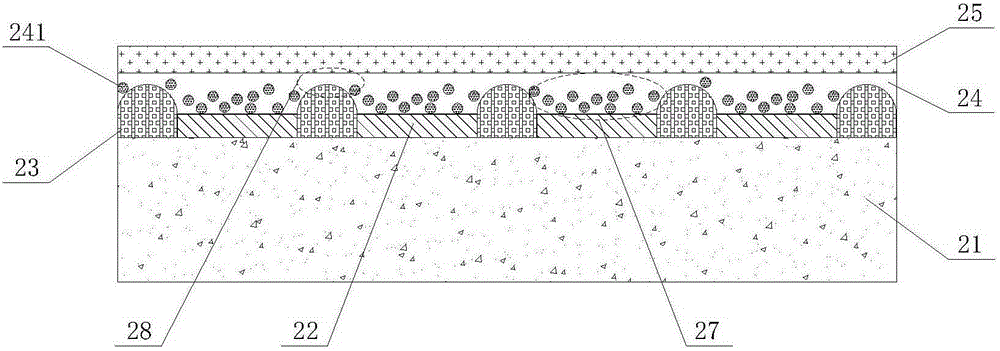

[0044] figure 2 It is a schematic diagram of the FOG structure in the embodiment of the present application; as figure 2 As shown, a display device in the embodiment of the present application may include, for example, a FOG structure formed after a hot-pressing process, and the above-mentioned display device may include:

[0045] A display panel 21, the display panel 21 may be an AMOLED glass substrate provided with a display module, or may be a panel for preparing other display devices, that is, the display panel 21 is provided with a light-emitting device; in addition , in order to facilitate the following explanation, define the surface of the display panel 21 through which the above-mentioned light-emitting device emits light is defined as the front surface (that is, the surface of the display substrate 21 located above in the figure of this embodiment is referred to as the front surface, and correspondingly, the surface located below is referred to as the front surface...

Embodiment 2

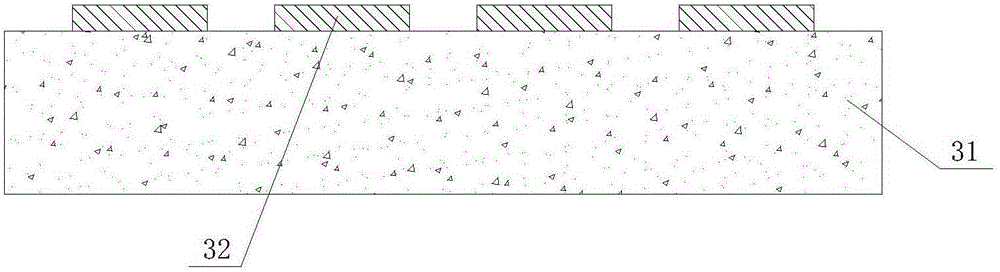

[0053] Figure 3-10 It is a schematic structural flow diagram of the method for preparing an organic light-emitting diode display panel in the embodiment of the present application; Figure 3-10 As shown, the present application also provides an organic light emitting diode display panel, which can be used to prepare a display device such as that in Embodiment 1 based on the traditional FOG structure (such as AMOLED FOG structure) preparation process, so as to effectively avoid adjacent The defects such as short circuit caused by the aggregation of conductive particles between the pads, and further improve the contact performance of the FOG structure in the display device, the above-mentioned methods specifically include:

[0054] First, if image 3 As shown, a display panel 31 is provided with a bonding area on its surface, and several welding pads 32 are provided on the surface of the display panel 31 located in the bonding area. The display panel 31 can be prepared with e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com