Waste gas treatment device and method by means of biological method

A technology of waste gas treatment and biological method, which is applied in the direction of gas treatment, separation methods, chemical instruments and methods, etc., can solve the problems of incomplete waste gas treatment, easy failure of secondary treatment, high investment in treatment equipment, and achieve short treatment time and high equipment Simple structure and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

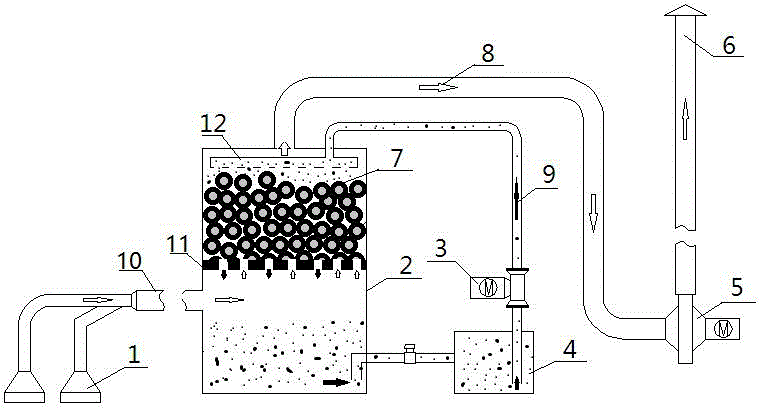

[0037] A device for biological waste gas treatment, including a gas flow system and a biological bacteria circulation treatment system, the gas flow system includes a gas collection port 1, a processor inlet pipeline 10, a fan 5, an exhaust port 6 and a gas flow pipeline 8. The biological bacterium circulation treatment system includes a bacterium incubator 4, a water pump 3, a biological processor 2 and a circulation pipeline 9; the biological processor includes an inert filler and a partition; the gas collection port 1 is connected to the air inlet pipe of the processor Road 10, the processor inlet pipeline 10 is located on the wall of the bioprocessor 2 barrel, below the partition and above the liquid surface of the bacteria; the top of the bioprocessor 2 is connected to the gas flow pipeline 8, and the gas flow pipeline 8 is provided with a fan 5, The upper end of the gas flow pipeline 8 is connected to the exhaust port 5; the bioprocessor 2 is closed-loop connected with th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap