Rotary type multi-nozzle proportional spray head

A multi-nozzle, rotary technology, used in spray devices, spray devices, liquid spray devices, etc., can solve the problems of inability to replace nozzles, detachment, and high processing costs, so as to reduce the matching accuracy and processing costs, and reduce the axial length. , The effect of smooth transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

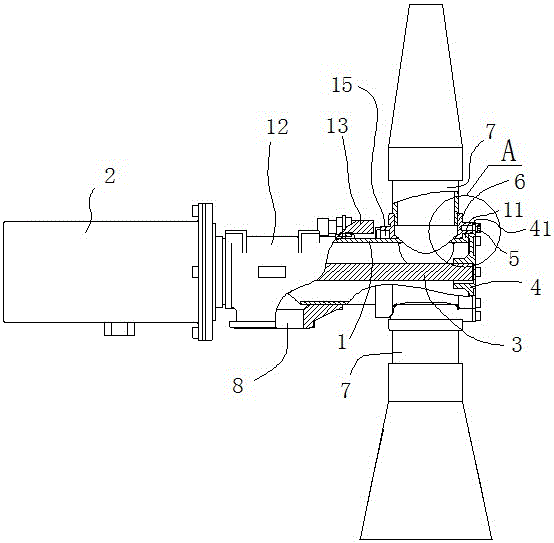

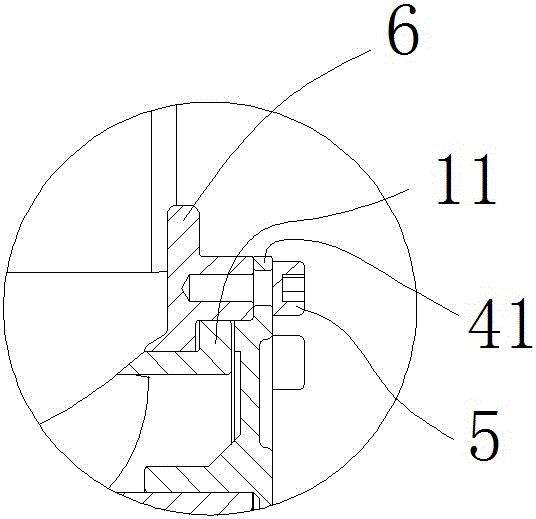

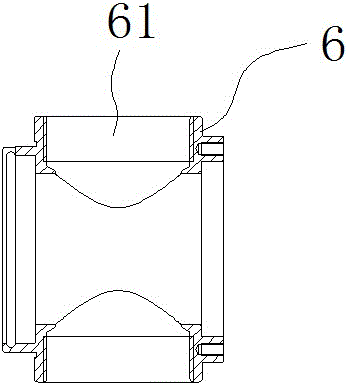

[0029] In order to make the technical solution of the present invention clearer, the following in conjunction with the attached Figures 1 to 10 , the present invention will be described in detail. It should be understood that the specific implementations described in this specification are only for explaining the present invention, and are not intended to limit the protection scope of the present invention.

[0030] The present invention is a rotary multi-nozzle proportional sprinkler head, comprising a water inlet pipe 1, the rear end of the water inlet pipe 1 is connected with a motor 2, and the motor 2 is connected with the transmission shaft 3 arranged in the water inlet pipe 1. The rotating end cover 4 of the front end port of the water pipe 1 is connected by transmission, and the rotating end cover 4 is provided with a radially extending portion 41, and the radially extending portion 41 is supported by a sliding member sleeved on the outer periphery of the front end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com