Intelligent ring sand box conveyor line

A technology of conveying line and sand box, which can be used in casting molding equipment, mold components, manufacturing tools, etc., and can solve problems such as insufficient intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

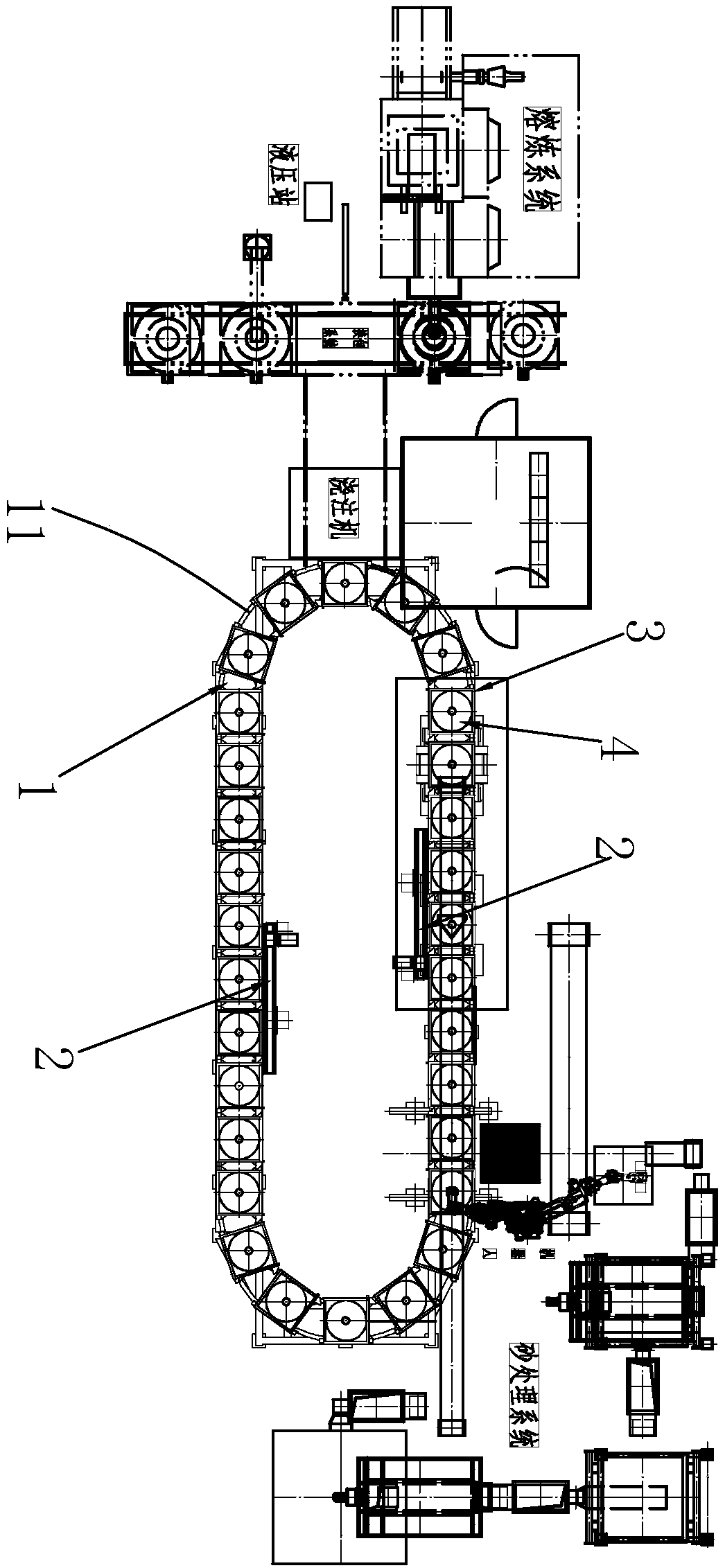

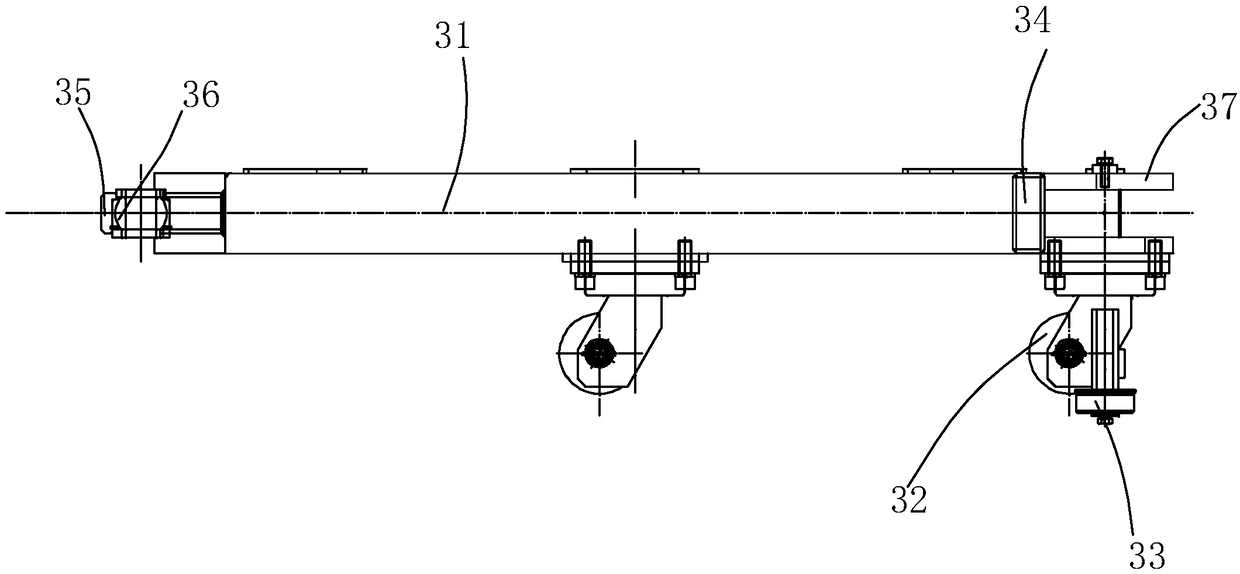

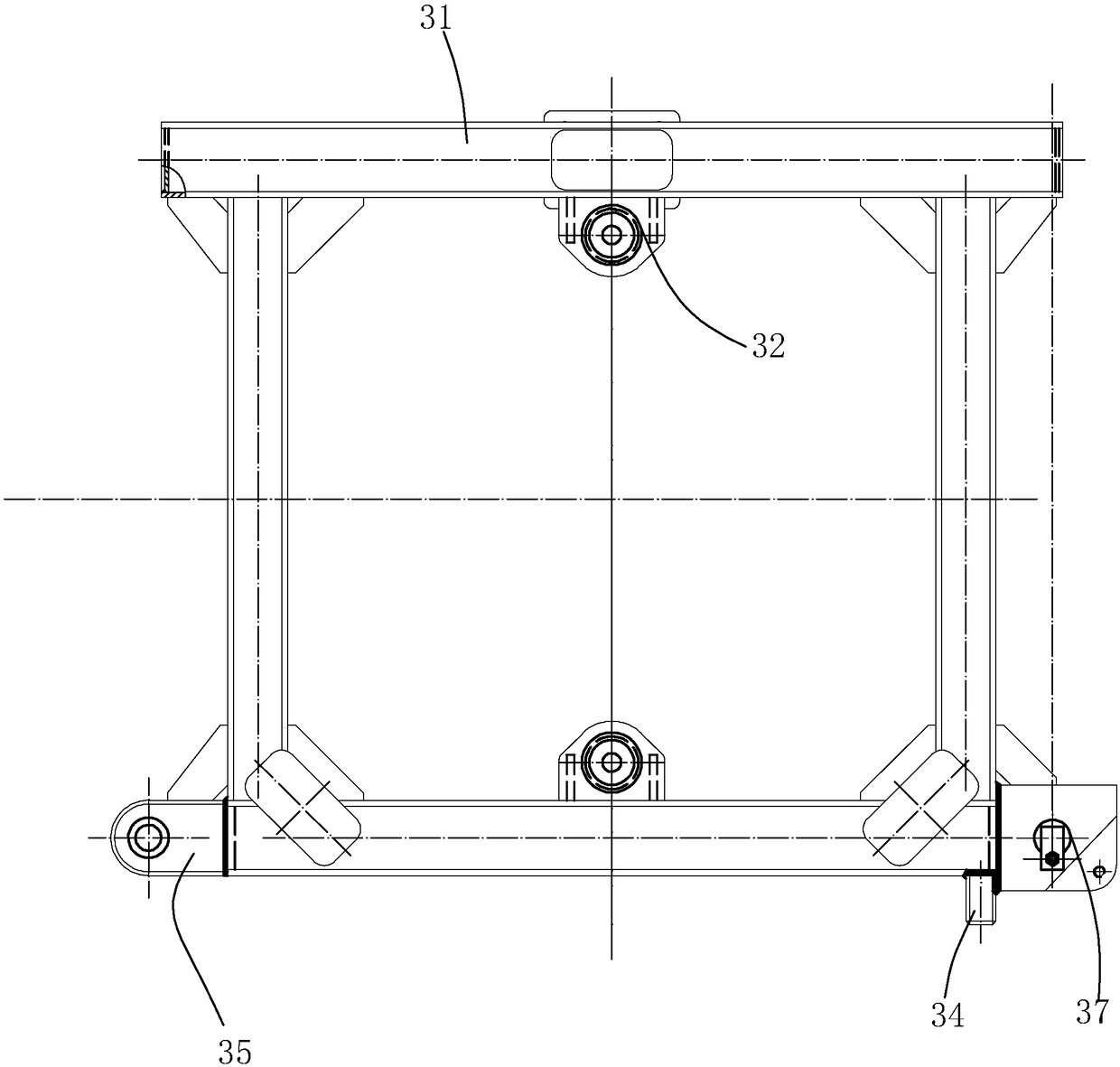

[0028] Such as figure 1 As shown, an intelligent circular sand box conveying line, the shape of the sand box automatic circulation line 1 is ring-shaped, and is composed of two parallel conveying tracks 11 and arc-shaped tracks located at the two ends of the two parallel conveying tracks 11, for supplying The sand-carrying trolley travels, and the box-carrying trolley 3 includes a vehicle frame 31, which is hollowed out in the center of the vehicle frame 31, which is applicable to the sand box 4 from the bottom unloading mode; A total of 4 universal wheels 32 arranged in a rectangular shape are arranged at the end, so that the box-carrying trolley 3 has the function of turning. It can be that the spacing between several pairs of universal wheels 32 remains the same, so that the stress on the conveying track 11 is more uniform; the two side guide wheels 33 of the universal wheels 32 at the rear end of the vehicle frame 31 are used to make the carrying case When the trolley 3 r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com