A microstructure cemented carbide turning insert for cutting 304 stainless steel

A technology of 304 stainless steel and hard alloy, which is applied in the direction of lathe tools, turning equipment, tool holder accessories, etc., can solve the problem of reducing cutting temperature, achieve increased contact area, obvious cooling effect, and improve durability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

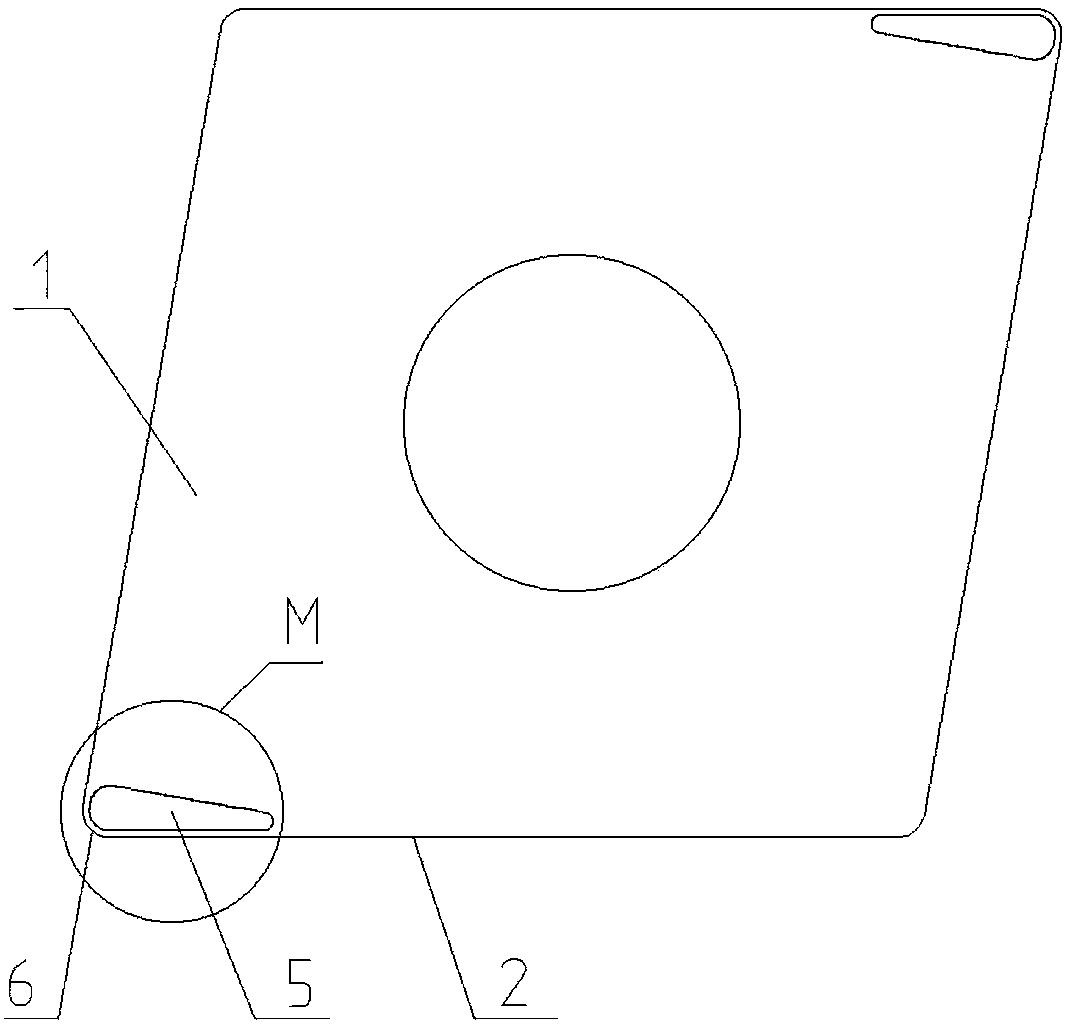

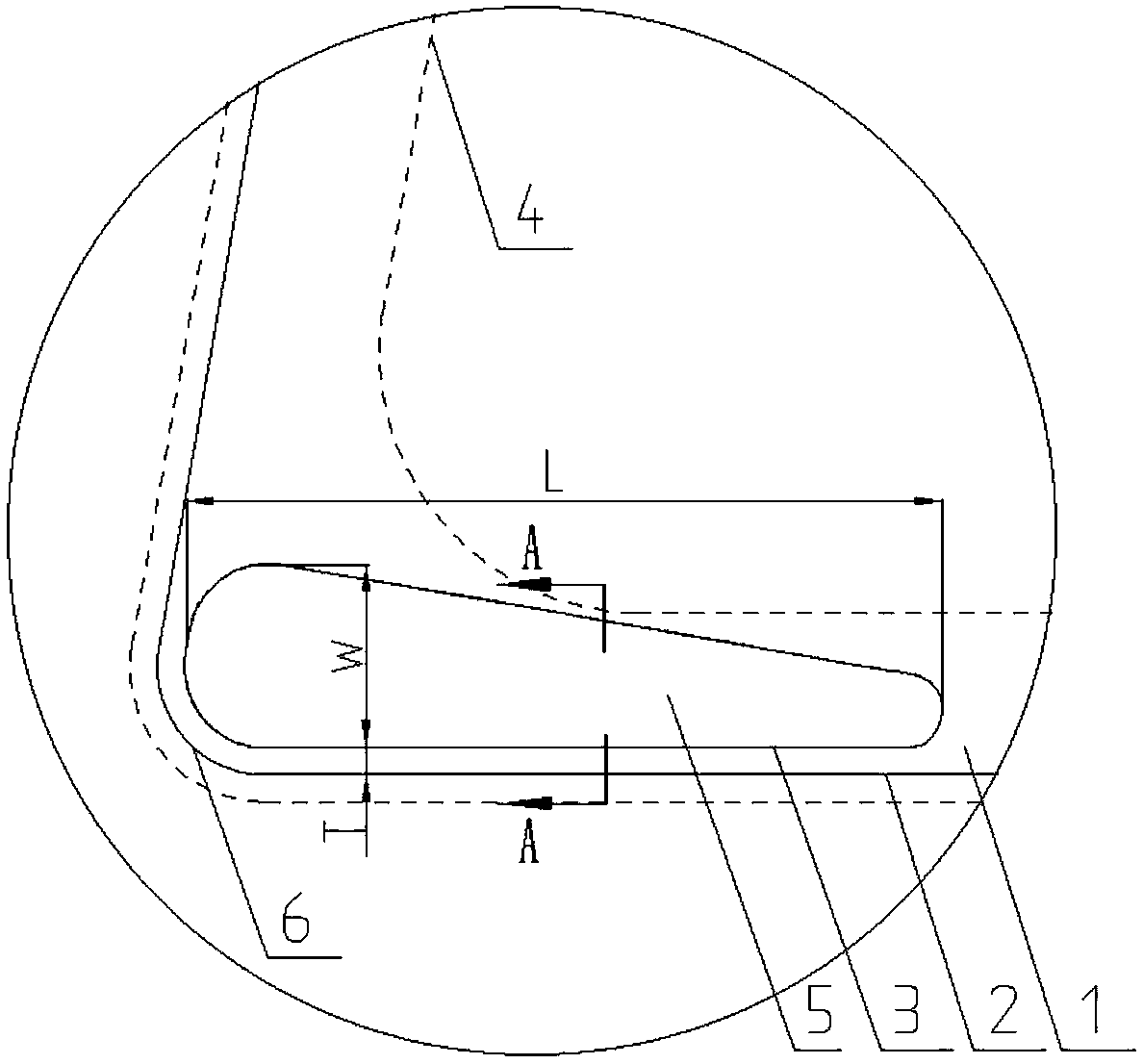

[0031] Example 1. A kind of microstructure cemented carbide turning blade for cutting 304 stainless steel, its composition is as follows figure 1 and 2 As shown, including the rake face 1, the edge of the rake face 1 is provided with a main cutting edge 2, and the cutting edge of the rake face 1 is provided with a microgroove 5 near the region 4; the microgroove 5 is asymmetrical and integral Baseball bat-shaped microstructures of unequal width and depth (such as figure 2 shown).

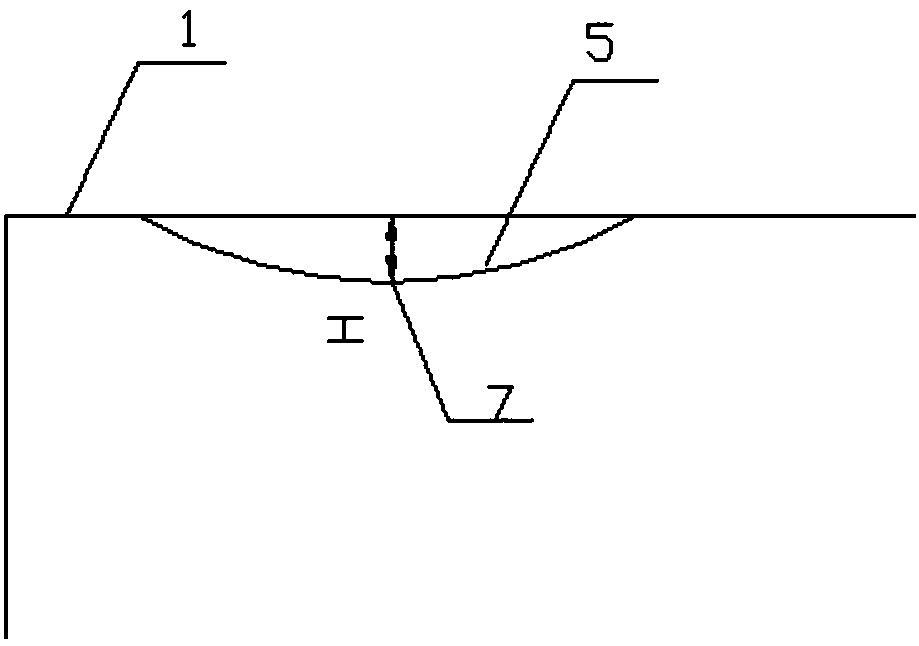

[0032] Aforesaid microgroove 5 (as image 3 As shown), the section of the microgroove 5 is asymmetrically curved, the bottom surface 7 of the microgroove 5 is flat or curved, and the maximum depth H of the microgroove 5 is 0.1-0.3mm.

[0033] The length L of aforementioned microgroove 5 is 1~3.5mm; The maximum width W of microgroove 5 (as figure 2 shown) is 0.5~2.5mm.

[0034] The distance T (such as figure 2 Shown) is 0.08 ~ 0.5mm, the optimum is 0.1mm.

[0035] The connection form between...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com