High-reliability oxide layer polishing device for copper-clad plate pretreatment

A pretreatment and oxide layer technology, which is applied in grinding/polishing equipment, metal processing equipment, and machine tools suitable for grinding workpiece planes, etc., can solve the problems of inability to grind copper clad laminates and high labor intensity of operators, and achieve structural The effect of simplicity, good plasticity and long working life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

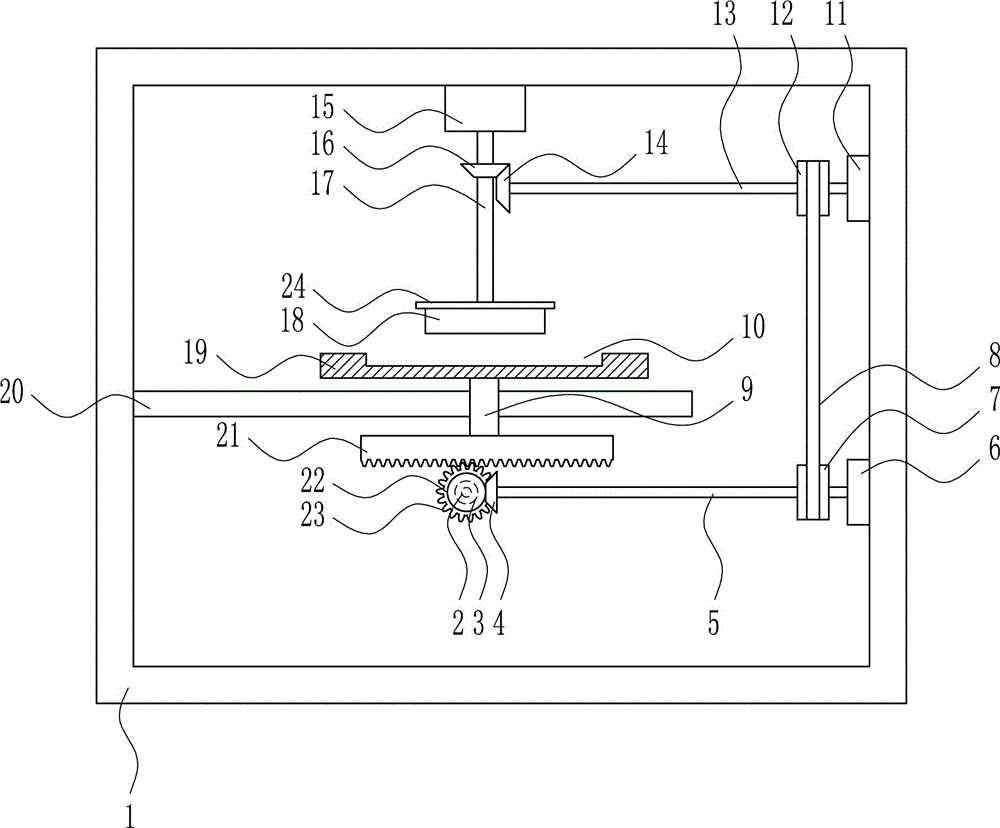

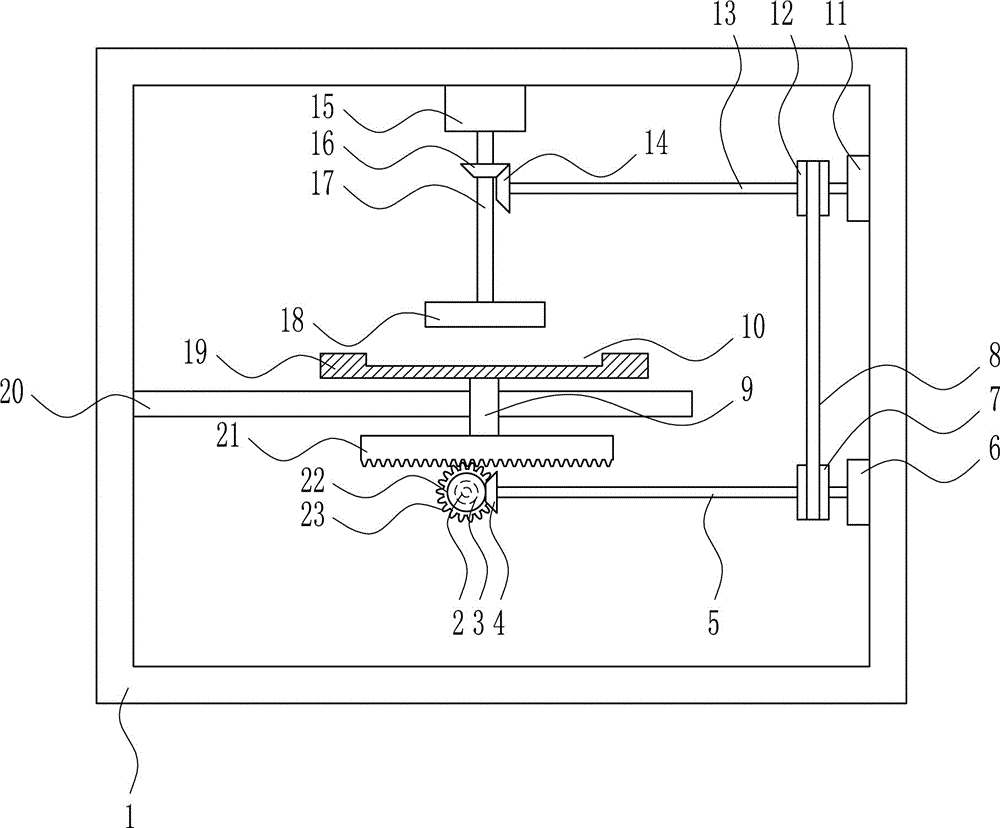

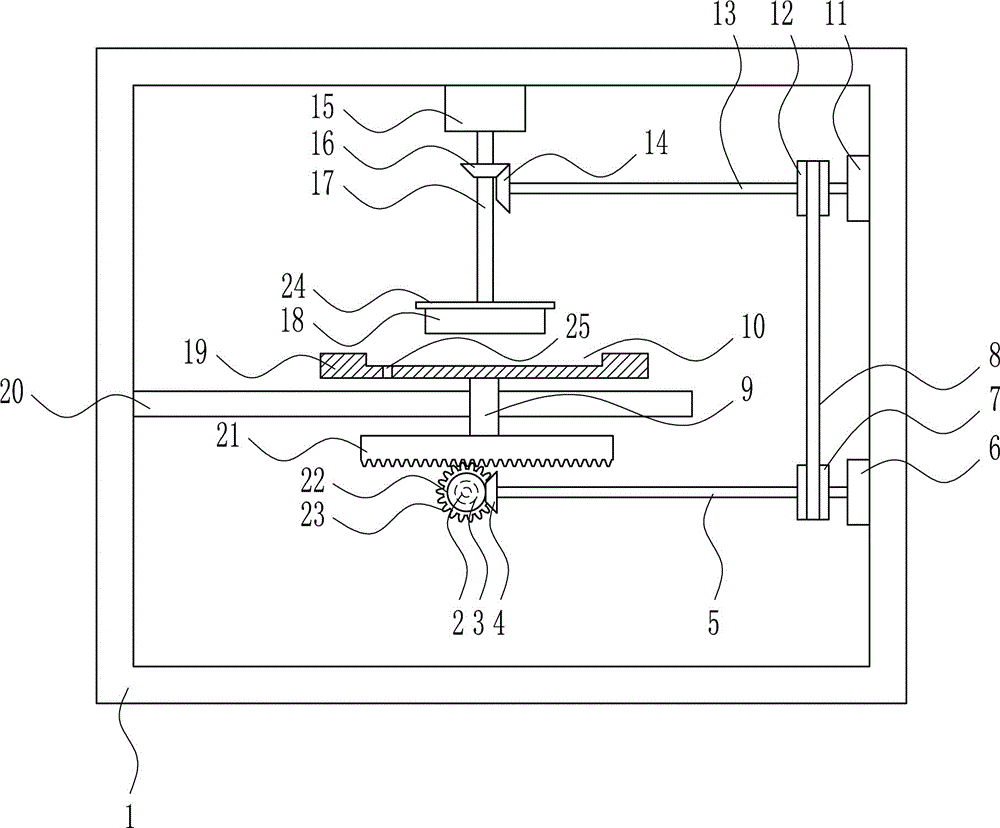

[0028] A high-reliability polishing equipment for the pretreatment of copper clad laminates, such as Figure 1-3 As shown, it includes a processing box 1, a first rotating shaft 2, a first bearing seat 3, a second bevel gear 4, a second rotating shaft 5, a second bearing seat 6, a second pulley 7, a flat belt 8, a slider 9, The third bearing seat 11, the first pulley 12, the third rotating shaft 13, the third bevel gear 14, the rotating electric machine 15, the fourth bevel gear 16, the fourth rotating shaft 17, the grinding block 18, the processing table 19, the slide rail 20, the tooth Strip 21, first bevel gear 22 and first gear 23; the inner right wall of the processing box 1 is connected with a third bearing seat 11 and a second bearing seat 6 by bolt connection, and the third bearing seat 11 is located in the second bearing seat 6 Above, the inner bearing of the third bearing housing 11 is connected to the third rotating shaft 13 by interference fit, and the third bevel g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com