A method for separating and purifying ginkgolide a and ginkgolide b

A technology of ginkgolide and ginkgo leaf, applied in the direction of organic chemistry and the like, can solve problems such as difficulty in obtaining high purity, and achieve the effects of wide health care range, high product purity and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

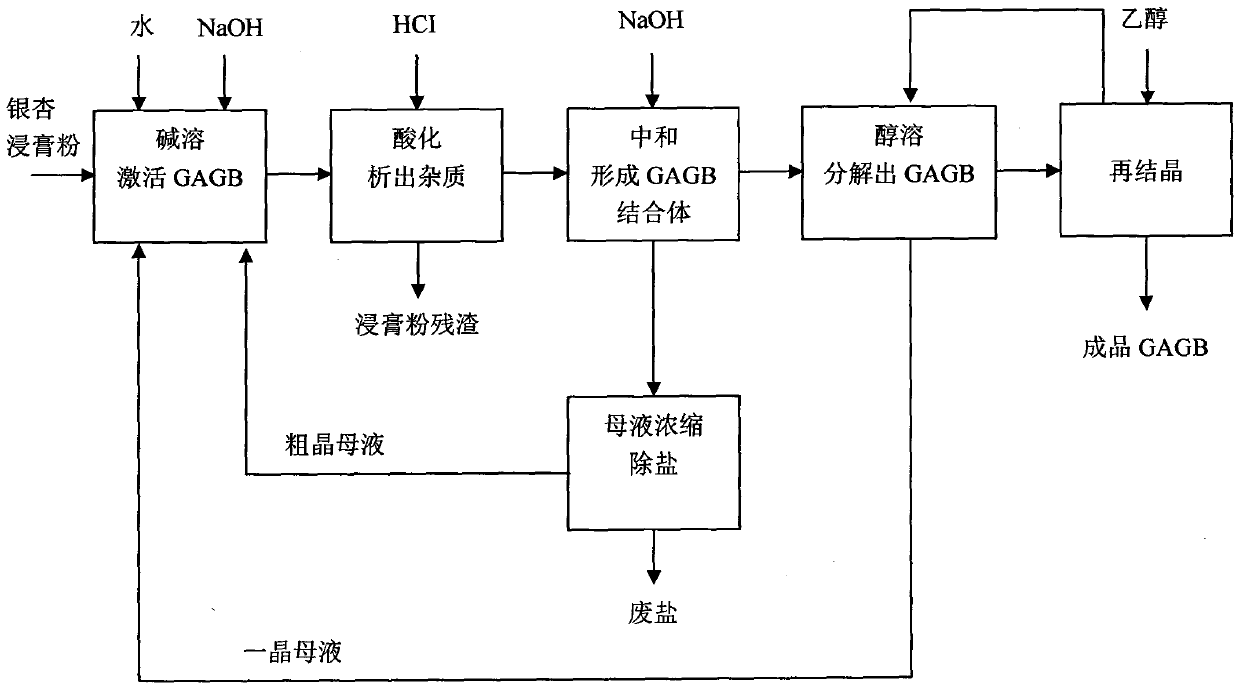

Method used

Image

Examples

Embodiment Construction

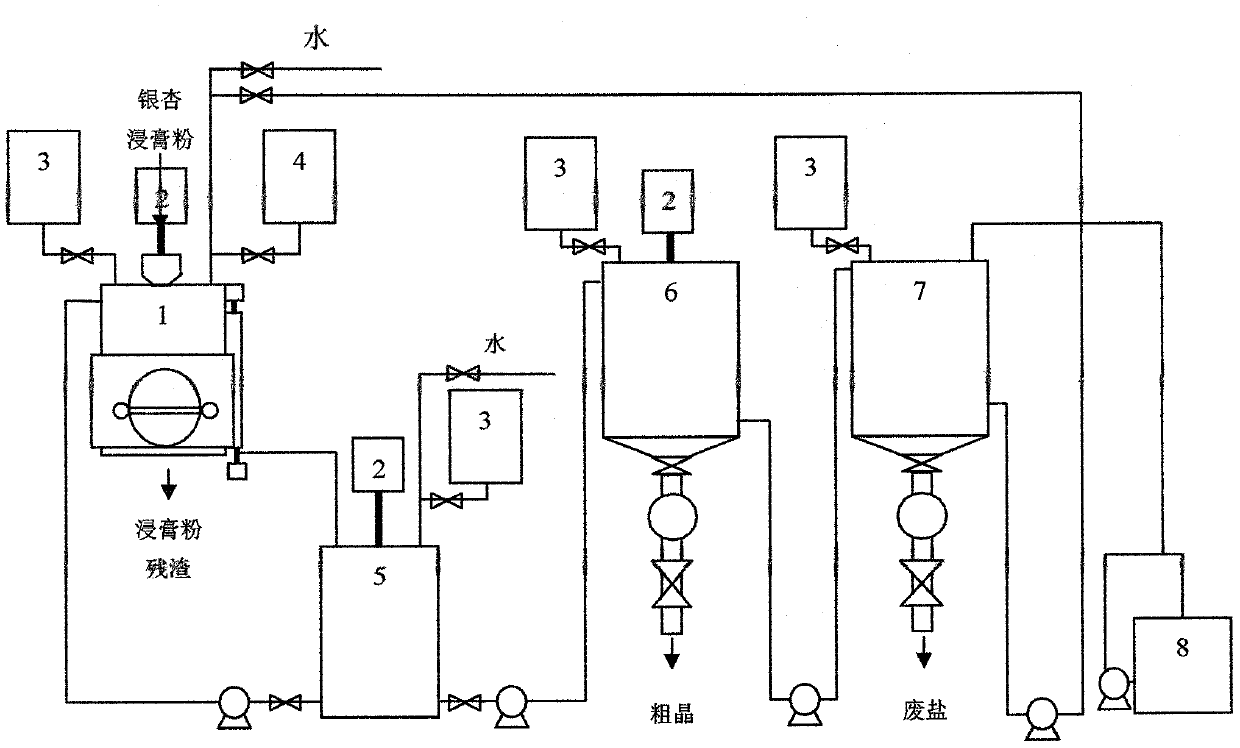

[0019] 1. Separator operation

[0020] 1. Ginkgo biloba extract powder is weighed and poured into the separator from the hopper.

[0021] 2. Put the concentrated coarse crystal mother liquor (60%) left over from the last purification, the precipitation chamber washing liquid (20%), the single crystal mother liquor (5%) and tap water (15%). The total material-to-liquid ratio is 1:18.

[0022] 3. Heat and start the stirrer, slowly add sodium hydroxide until the pH is about 8.0, the extract powder and lye are in a semi-dissolved state, and GA and GB are activated and dissolved.

[0023] 4. After ten minutes, turn on the separator cooling water, cool to room temperature, slowly put in hydrochloric acid, until PH2.0-2.5, stop stirring, the solution precipitates colloidal impurities

[0024] 5. Decant the liquid and flow to the settling tank.

[0025] 6. Open the slag outlet of the separator, clear out the extract powder residue, and dispose of it.

[0026] 2. Settling tank oper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com