Practical cross-linking apparatus

A cross-linking device and a practical technology, applied in the field of practical cross-linking devices, can solve the problems of easy water ingress, being affected by distance, reducing charging current and ground fault current, etc., and achieving no basic operating cost and comprehensive operating cost. Low, stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

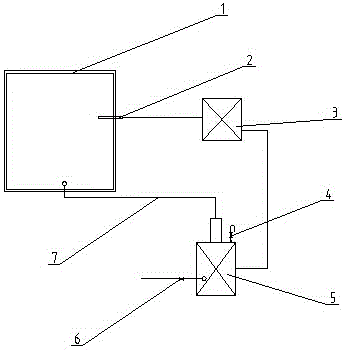

[0008] A practical cross-linking device, the cross-linking device includes a cross-linking box 1, a steam generator 5, a controller 3, the bottom of the cross-linking box 1 is provided with a steam pipeline 7 and connected with the steam generator 5 A thermocouple 2 is provided in the middle of the cross-linking box 1, and the temperature measurement signal is sent to the controller 3 to control the opening and closing of the steam generator 5. The steam generator 5 is provided with a pressure safety valve 4, and the steam A water inlet pipe 6 is provided at the bottom of the generator 5 .

[0009] The cross-linked box 1 is made of double-layer stainless steel plate to prevent corrosion in repeated high-temperature and high-humidity environments. The double-layer stainless steel plate is filled with a thermal insulation layer to prevent temperature loss from affecting the temperature rise rate and unnecessary energy waste. One side is equipped with a sealed door, which is conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com