Improved Blast Furnace Soft Water Closed Circulation System and Method

A soft water closed and circulating system technology, applied in cooling devices and other directions, can solve the problems of safety, potential safety hazards, not allowing long-term search and location of cooling wall leakage points, etc., to achieve the effect of improving efficiency and reducing the number of inspections

Active Publication Date: 2018-08-14

HUATIAN ENG & TECH CORP MCC

View PDF10 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

1) The existing soft water closed cycle cooling system uses a single main water supply pipe for water supply. Due to the continuous cooling requirements of the blast furnace, in addition to the overhaul time, there is no time for maintenance and replacement of the valves and testing equipment on the main water supply pipe, which increases the The working time of valves and testing equipment increases fatigue and poses potential safety hazards;

2) The secondary circulation of the existing soft water closed circulation cooling system is located between the return water branch pipe and the degassing tank. The secondary circulation cooling equipment bears additional system static pressure, which is easy to cause water leakage, and the secondary circulation cooling has not been degassed. Gas disposal increases the risk of local overheating of the secondary circulation cooling equipment, posing potential safety hazards;

3) The existing soft water closed circulation cooling system is in a closed state, and the cooling wall has a large number of water pipes. Once a leakage point occurs, it takes a long time to find and locate it. However, there is blast furnace gas around the blast furnace body, so it is not allowed to search and locate cooling wall leakage for a long time dot homework

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

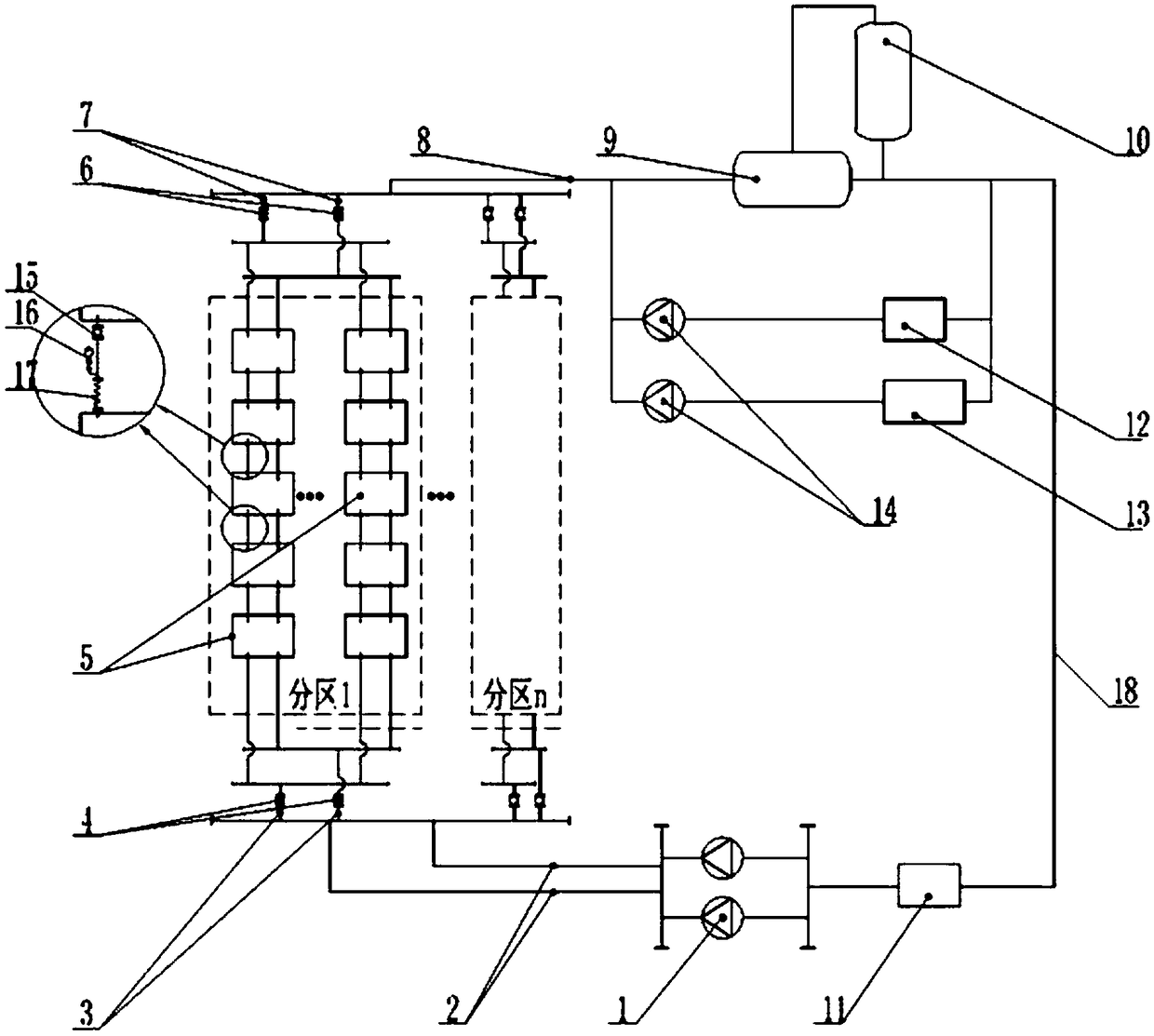

The invention discloses an improved blast furnace soft water closed circulation system and method. The system comprises a host controller, a cooling wall cooling unit, an expansion and degasification unit, a secondary circulation water unit and a primary circulation water supply unit. According to the improved blast furnace soft water closed circulation system and method, multiple water supply main pipes are adopted, the redundancy degree of the system is increased, and blast furnace production safety is guaranteed; a cooling wall is zoned, grading and leakage detecting are facilitated, the time needed for leakage detecting is reduced, and guarantees are provided for stable production and cost reduction; and secondary circulation water setting is reasonable, the work pressure of secondary circulation water cooling equipment is reduced, the risk of water leakage is reduced, and the gas contents in primary circulation water and secondary circulation water are reduced.

Description

technical field The invention relates to the technical field of molten steel smelting equipment, in particular to an improved airtight circulation system for soft water in a blast furnace, and also to a method. Background technique The blast furnace cooling system mainly includes two types: the industrial water open circuit cooling system and the soft water closed circulation cooling system. The soft water closed circulation cooling system has the following main advantages over the industrial water open circuit cooling system: the cooling pipe is not easy to scale, the water is underheated (less circulating water can be used), the loss of water is small, the potential energy of the water level can be used, and the oxygen content in the water is low. It is a system that is more energy-efficient, saves investment and operating costs. After 2005, newly-built domestic blast furnaces basically adopt soft water closed circulation cooling system. After more than ten years of large...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C21B7/10

CPCC21B7/10

Inventor 董建民

Owner HUATIAN ENG & TECH CORP MCC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com