Assembled PC component door/window system

A prefabricated and component technology, applied in the directions of sealing devices, frame fixing, and joint fastening/covering, etc., can solve the problems of troublesome construction, affect the appearance, and the waterproof effect is not good enough, so as to avoid damage and enhance flexibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

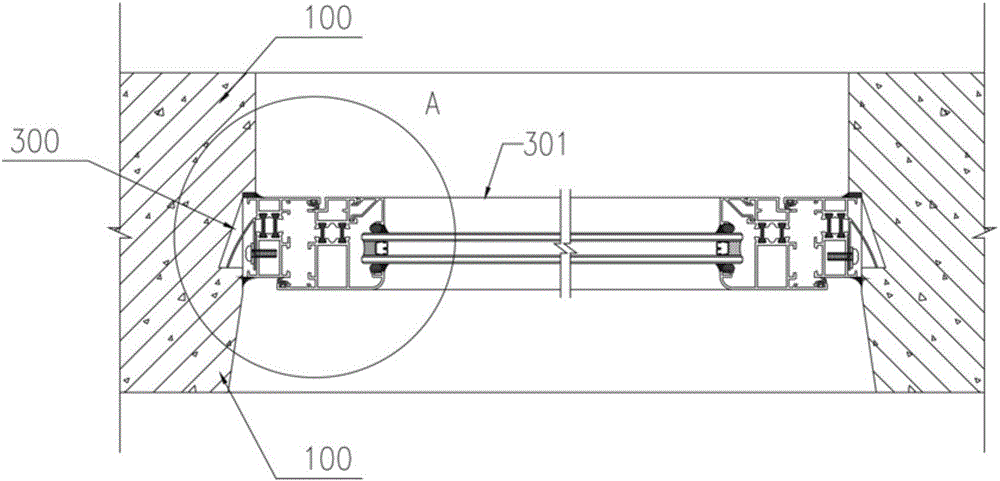

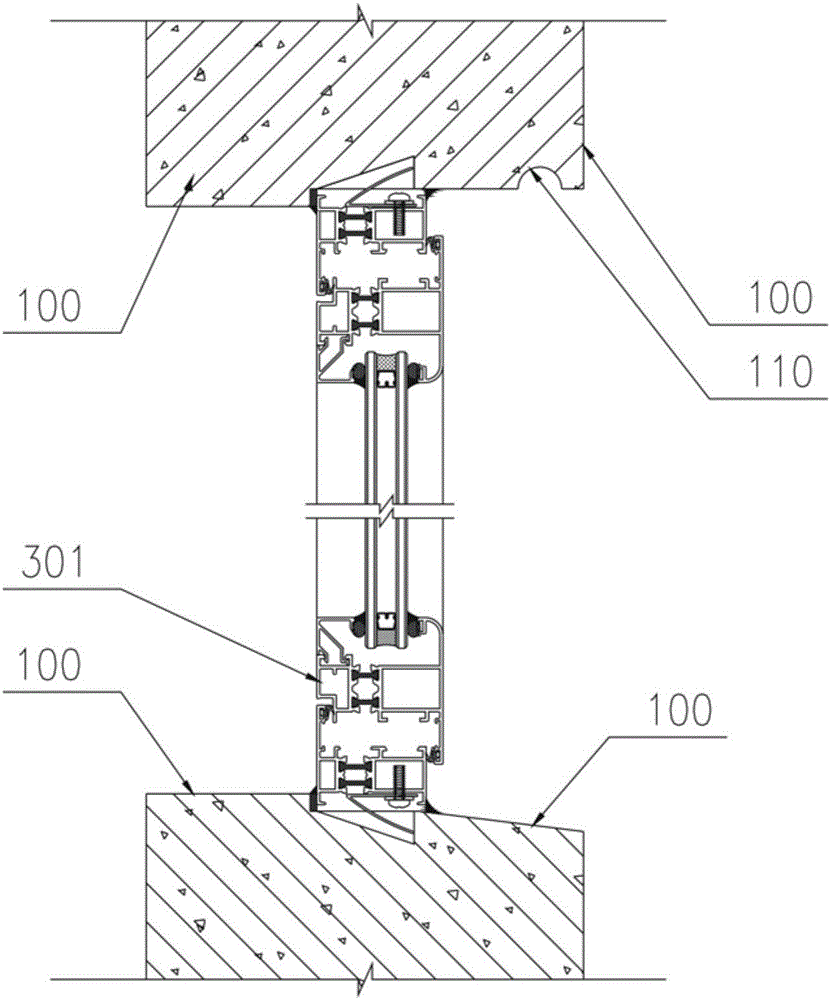

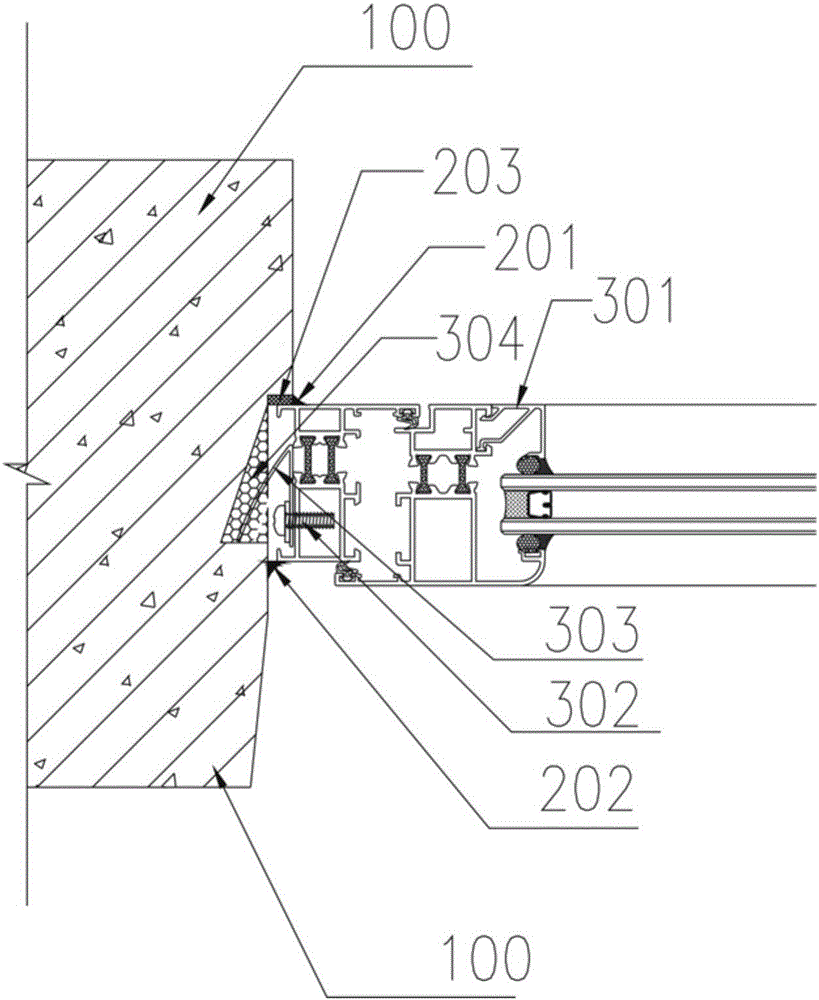

[0031] An assembled PC component door and window system, comprising a wall 100, an installation opening, a door and window frame 301, and connectors, the installation opening is set on the base of the wall 100, and the installation opening is provided with the door and window frame 301, The door and window frame 301 is fixedly connected to the wall body 100 through the connecting piece. The installation opening is opened on the wall, and the installation opening includes a notch 300, which is a groove with an opening at one end formed along the depth direction of the wall, and the notch 300 is filled with Sealant 304.

[0032] The cross-sectional shape of the notch 300 is triangular or rectangular, more specifically, it is a shape formed by a corner of a triangle and two sides where the corner is located, or a shape formed by three successively connected sides of a rectangle. The installation opening also includes a shoulder, and a limiting block 203 is arranged between the d...

Embodiment 2

[0036] The difference between this embodiment and Embodiment 1 is that an embedded part is provided in the notch 300, and the embedded part is fixedly connected with the wall, and the embedded part includes an embedded groove 305 , anchor bar 306, the anchor bar 306 is fixedly connected with the embedded groove 305, the embedded groove 305 is firmly lined in the notch 305, and the cross-sectional shape of the embedded groove 305 Consistent with the notch 300 . Further, the sealant 304 is filled in the pre-embedded groove 305 . The anchor bar 305 is embedded into the base body of the wall 100 like a nail, and the direction in which the anchor bar 305 is embedded in the wall 100 is perpendicular to the bottom surface of the embedded groove 305, so that the spring sheet 303 is stressed At this time, the pre-embedded groove 305 can provide the maximum supporting effect, thereby ensuring the firmness and stability of the door and window system. The pre-embedded groove 305 can eff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com