Vacuum sound-insulation glass door

A glass door and vacuum technology, applied in the field of indoor building doors, can solve the problems of hindering the transmission of sound, reducing the air tightness between the glass, and low precision, and achieves a long service life, a good sound insulation effect, and a prolonged holding time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

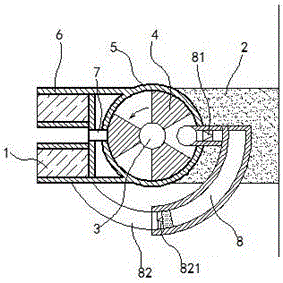

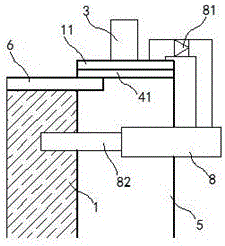

[0020] exist figure 1 , figure 2 In the shown embodiment, the vacuum soundproof glass door includes a glass sheet 1 and a frame;

[0021] The frame includes a fixed frame 2 and a fixed shaft 3, and an isolation fan 4 is sleeved on the fixed shaft 3. Outside the isolation fan 4, a rotating drum 5 is coaxially sleeved, and the rotating drum 5 is connected to the isolation fan 4. The fans 4 are connected by one-way bearings 41; the fan pieces of the isolation fan 4 are in airtight contact with the inner cylinder wall of the rotating drum 5; sealing plates 11 are also fixedly arranged at both ends of the fixed rotating shaft 3;

[0022] During the rotation of the drum 5, the outer wall of the drum 5 is in airtight sliding contact with the fixed frame 2, and the two end surfaces of the drum 5 are in airtight sliding contact with the sealing plate 11;

[0023] A glass clip 6 is arranged on the outer cylinder wall of the rotating drum 5, and the two glass clips 6 fasten and hold a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com