A coal seam drilling and fixing device

A technology for fixing holes and coal seams, applied in drill pipes, drill pipes, drilling equipment, etc., can solve problems such as drilling blockage and scrapping, reduce man-hours and material waste, improve the qualified rate of drilling holes, and solve the problem of hole collapse and blockage. Scrap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

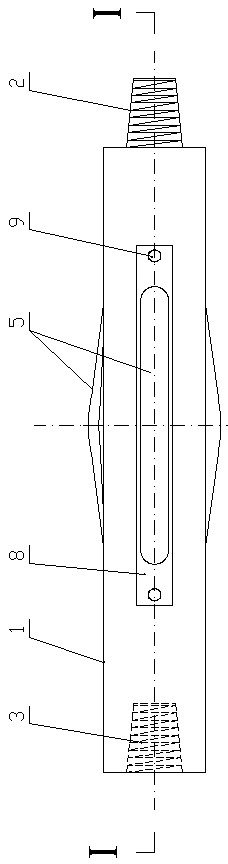

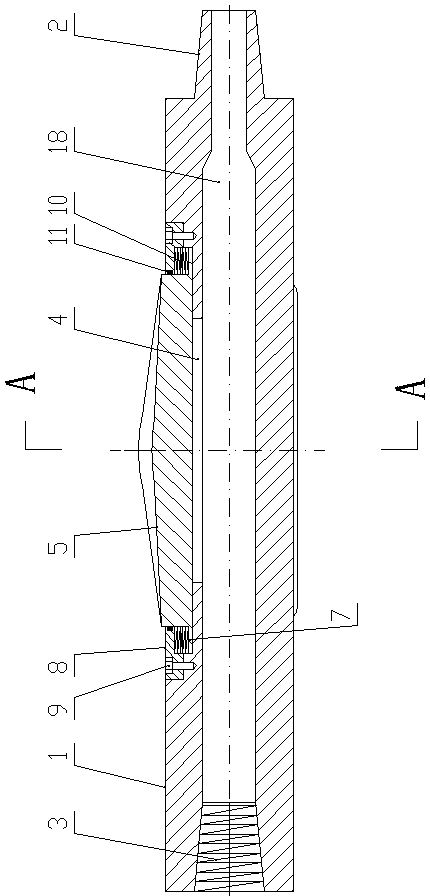

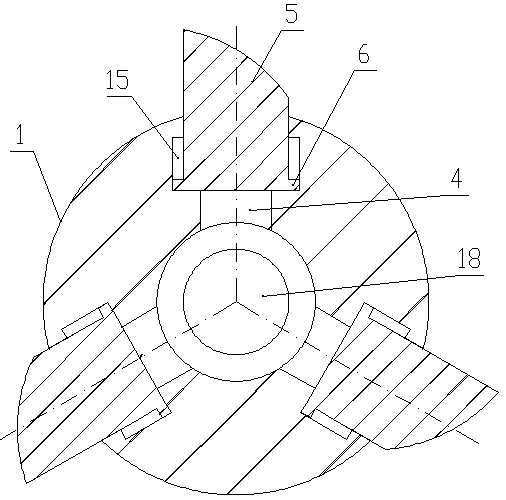

[0027] Such as Figure 1-Figure 5 As shown, a coal seam drilling and fixing device of the present invention includes a cylindrical body 1 with a central passage, and the two ends of the cylindrical body 1 are coaxially provided with a male connector 2 and a female connector 3 respectively. 1. The outer surface is evenly provided with at least two telescopic fixed hole structures along the circumferential direction.

[0028] Each telescopic fixed hole structure includes a long slot 15 opened along the axial direction of the cylinder 1, and the bottom of the long slot 15 on the cylinder 1 is provided with a through hole 4 whose length and width are smaller than the long slot 15. 15 is provided with a bidirectional conical rotor 5 protruding from the outer surface of the cylindrical body 1, the side of the bidirectional conical rotor 5 is symmetrically provided with a first guide plate 6 along the length direction, and the side of the bidirectional conical rotor 5 is along the T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com