Old-fashioned air conditioner electric auxiliary heating system, control method and air conditioner comprising old-fashioned air conditioner electric auxiliary heating system

An electric auxiliary heating and air conditioning technology, applied in space heating and ventilation, space heating and ventilation details, heating and ventilation control systems, etc., can solve the problems of quartz tubes being easily damaged, high production cost, and low energy-saving effect , to improve safety, reduce power consumption, and work stably

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

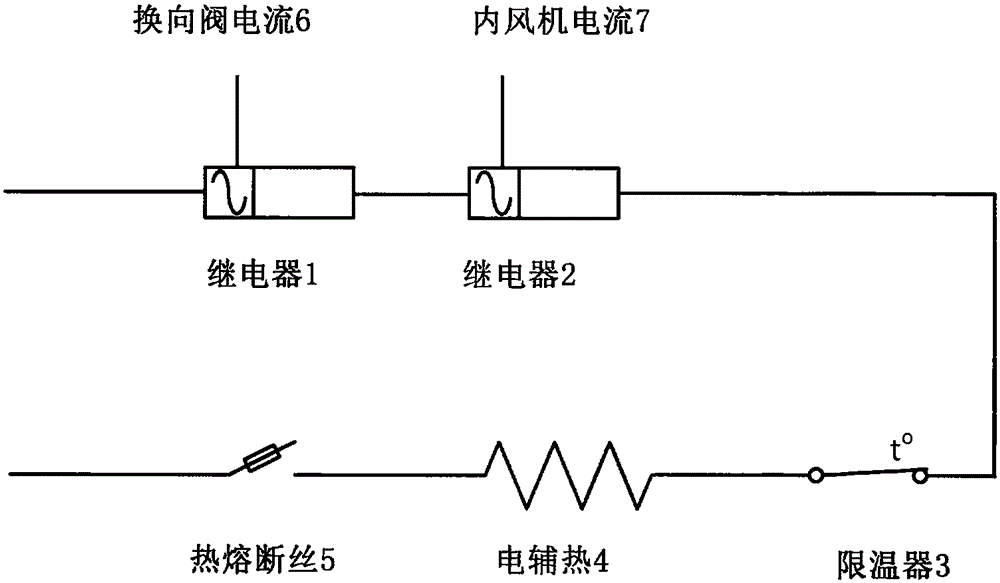

[0022] Such as figure 1 As shown, the electrical auxiliary heating system for old-fashioned air conditioners of the present invention is characterized in that the electrical auxiliary heating system includes a first relay 1, a second relay 2, a temperature limiter 3, an electrical auxiliary heating 4, and a thermal fuse 5 , reversing valve current 6 and internal fan current 7; the live wire is connected to the input terminal of the first relay 1, the control terminal of the first relay 1 is connected to the reversing valve current 6, and the output terminal of the first relay 1 is connected to the second relay 2 The input terminal of the second relay 2 is connected to the internal fan current 7, the output terminal of the second relay 2 is connected to one end of the temperature limiter 3, and the other end of the temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com