Absolute measurement method of homogeneity of optical flat

A parallel plate and absolute measurement technology, applied in the field of optical interferometry, can solve problems such as inconvenient operation, complicated operation, and inability to obtain quantitative results, and achieve the effect of less steps and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

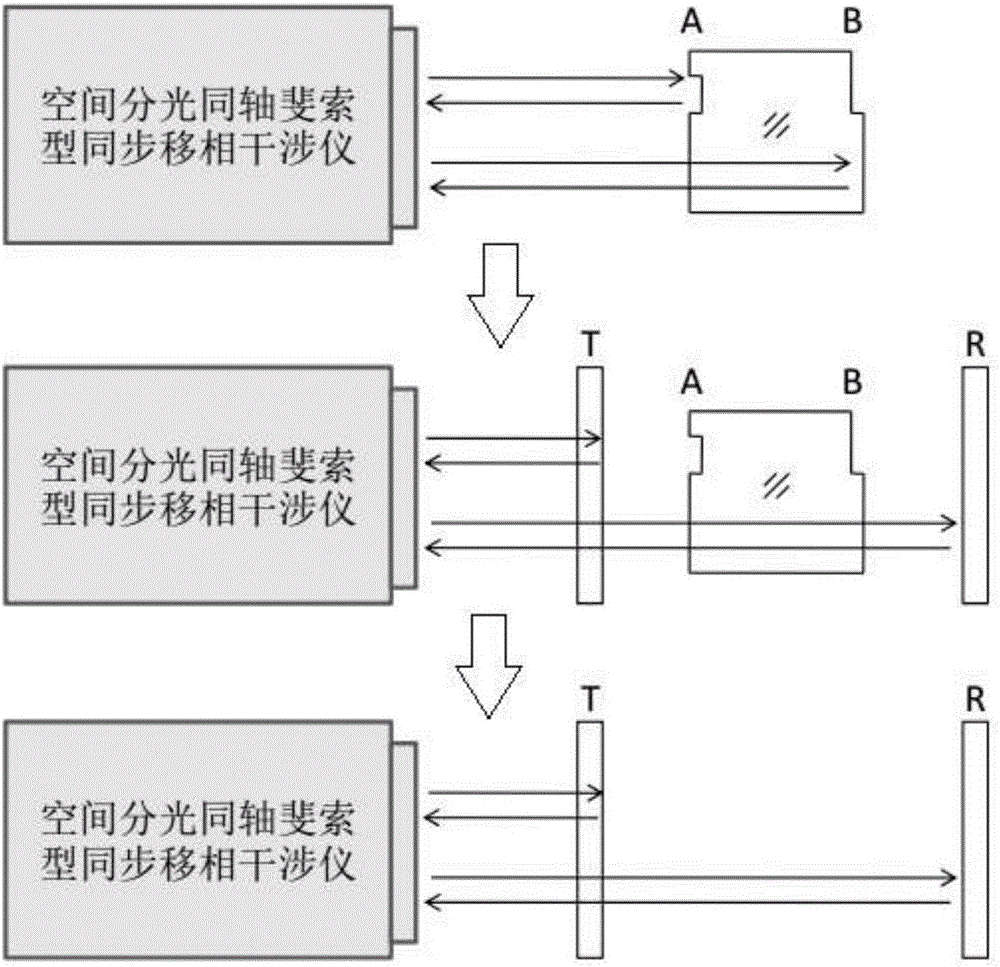

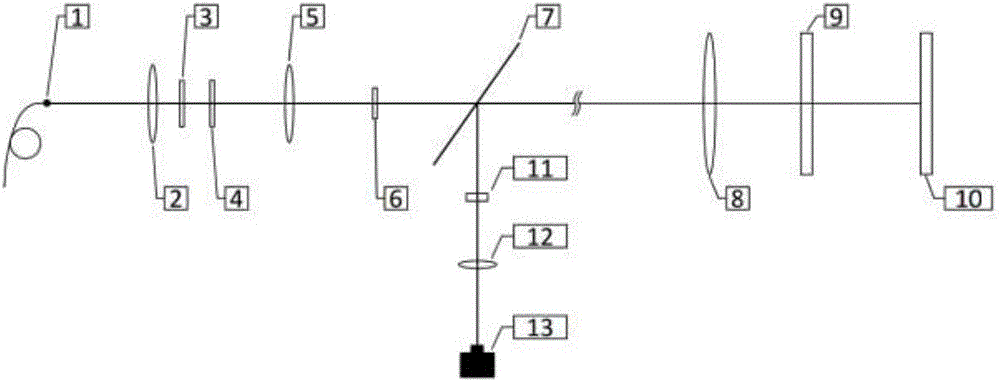

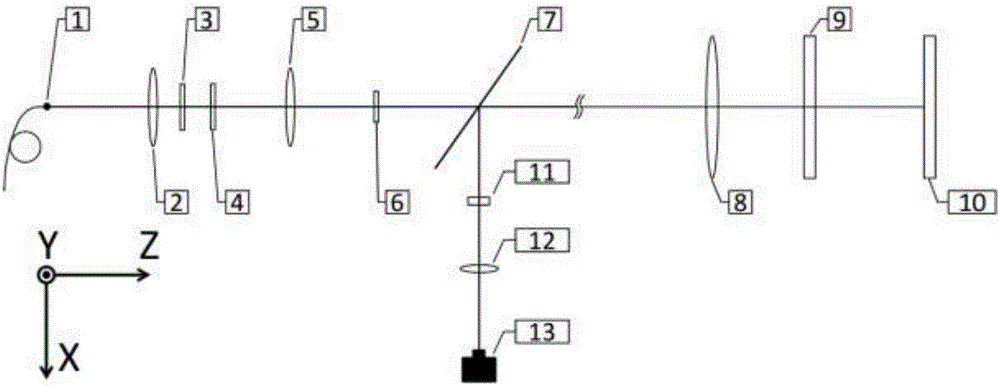

[0076] The absolute measurement method for the uniformity of optical parallel flat glass of the present invention is based on the spatial spectroscopic coaxial Fizeau type synchronous phase-shifting interferometer system, adding a λ / 4 wave plate between the collimating lens and the checkerboard grating, and adjusting the λ / 4 The angle of the wave plate makes the laser light emitted by the light source system circularly polarized, which specifically includes the following steps:

[0077] Step 1, put the optical parallel plate to be measured into the measurement optical path, and measure the wavefront deviation of the interferometric cavity formed by the front and rear surfaces of the optical parallel plate, as follows:

[0078] (1.1) Adjust the three-dimensional posture of the optical parallel plate to be measured so that the light returned from the front surface is self-collimated and returns to the light source system. In addition, the reference flat crystal and the reflectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com