An integrated wellhead detection device for drill string damage

A detection device and drill string technology, applied in the field of oil drill string damage wellhead detection device, integrated wellhead detection device for drill string damage, can solve the problem of inability to distinguish the stress state of variable diameter point and thread root, excitation coil and detection probe combination structure Large, abnormal stress concentration and micro-cracks, etc., to achieve accurate and reliable detection results, small size, and large diameter change range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments. However, it should be understood that the accompanying drawings are provided only for better understanding of the present invention, and they should not be construed as limiting the present invention.

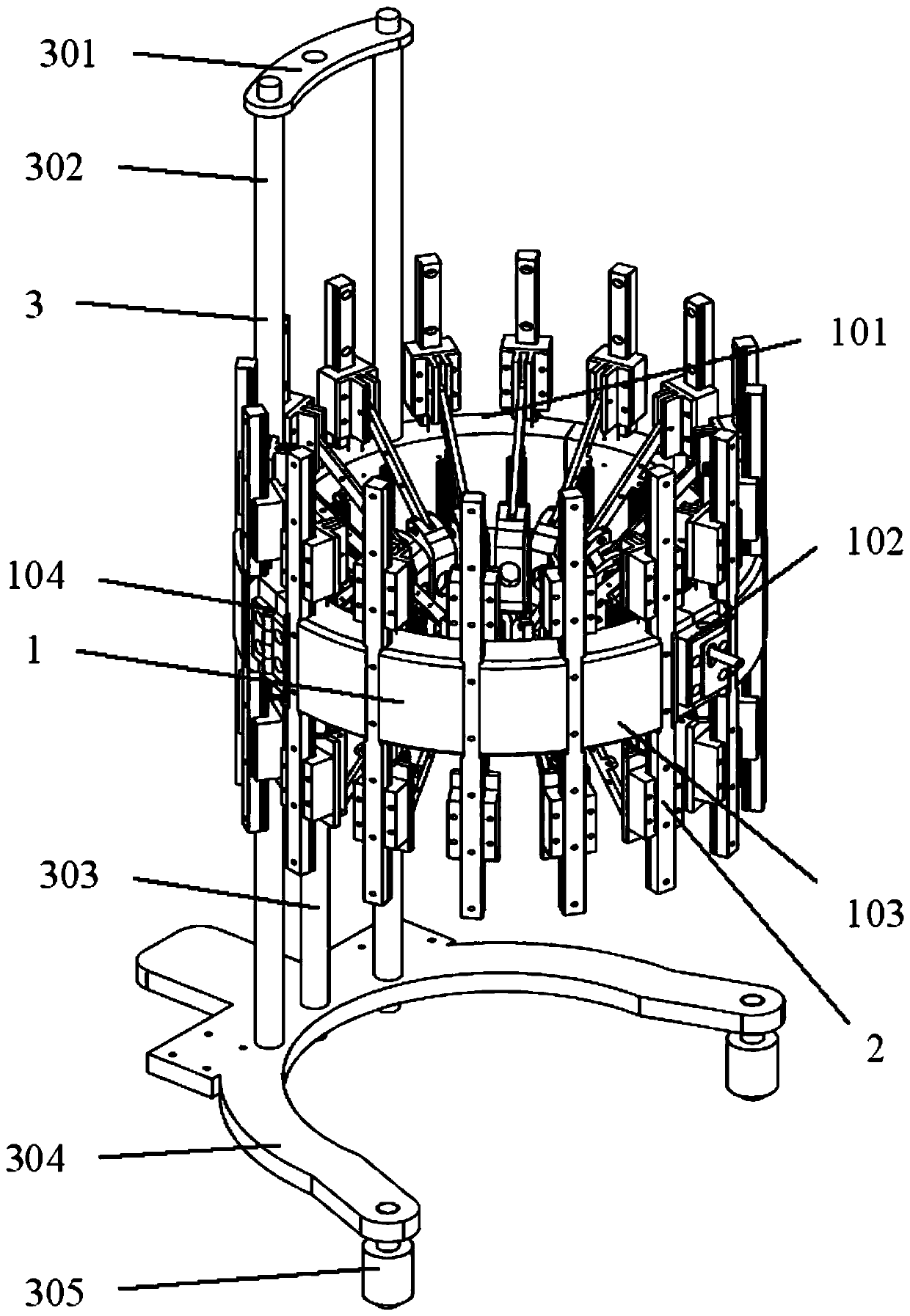

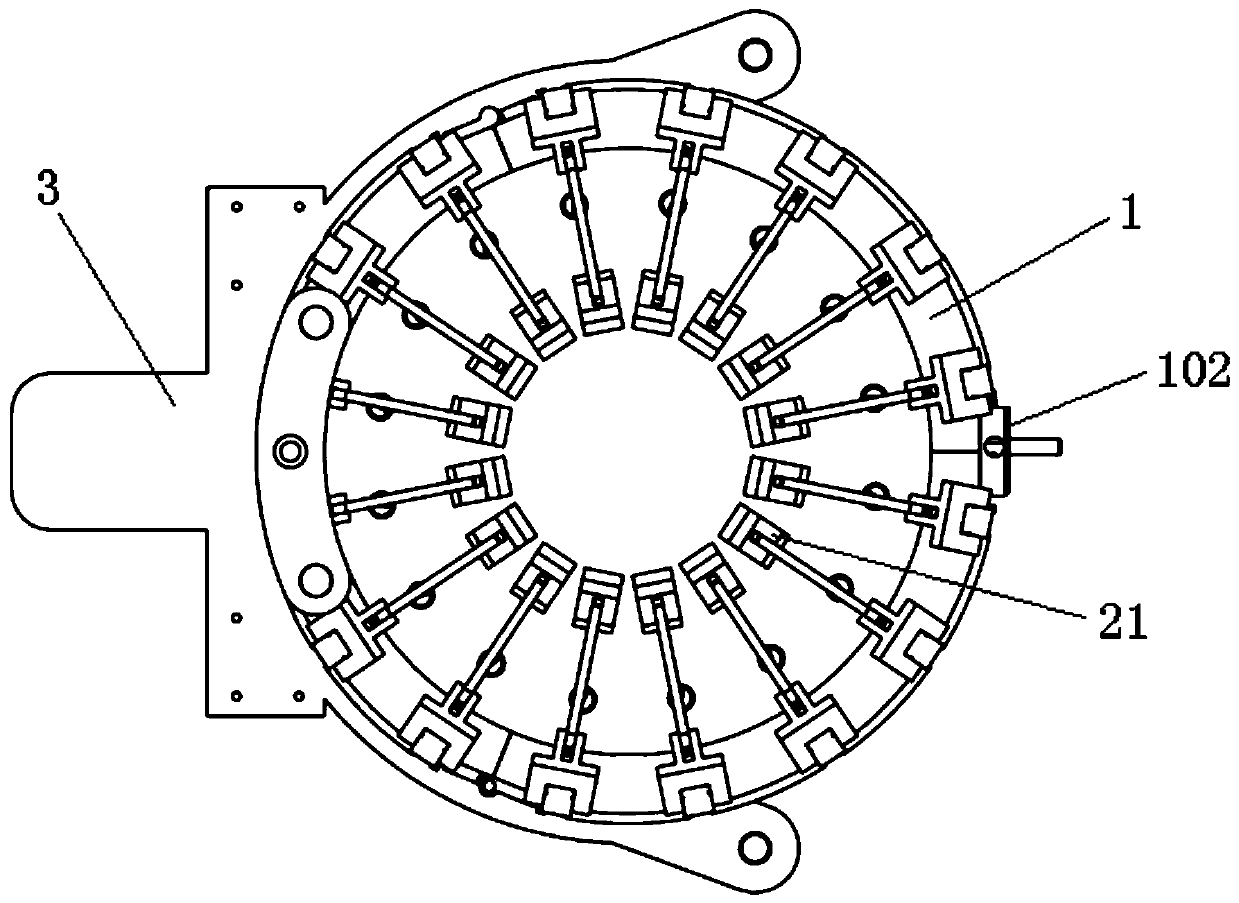

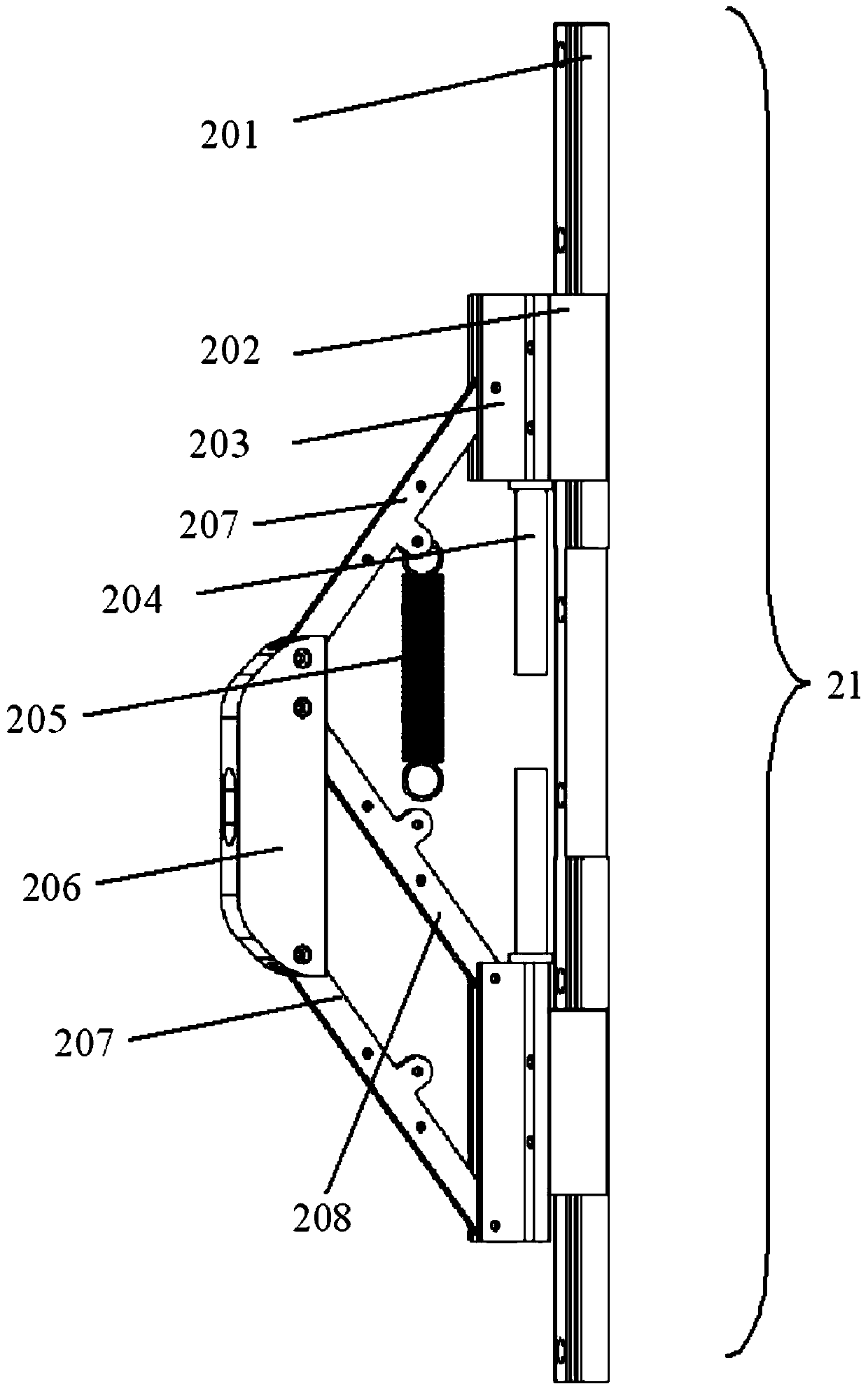

[0017] Such as figure 1 , figure 2 As shown, the present invention provides an integrated wellhead detection device for drill string damage, which is used to detect stress concentration in various parts of the drill string. The detection device includes a ring frame 1 and a detection assembly 2 .

[0018] Wherein, the ring frame 1 is mainly composed of a fixed ring 101 , a spring lock 102 , an opening and closing half ring 103 and a hinge 104 . The fixed ring 101 is a 1 / 3 circular ring (this is only an example, not limited to this), and the two sides of the fixed ring 101 are pivotally connected with an opening and closing half ring 103 through hinges...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com