Method for measuring and calibrating flow volume and velocity of numerically controlled shot blasting machine

A flow rate, shot blasting machine technology, applied in the detection field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

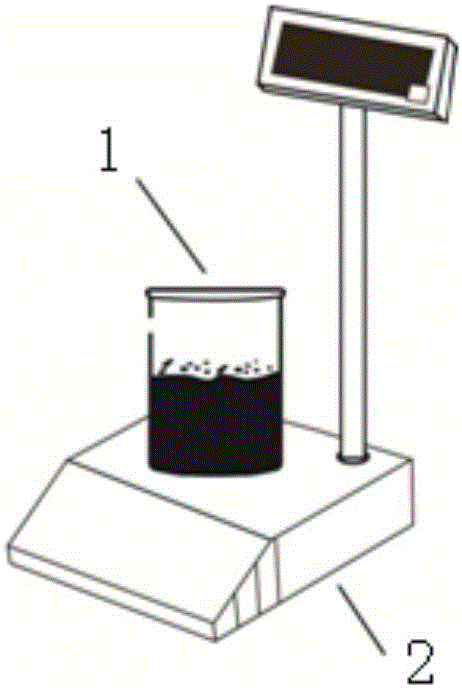

[0029] See attached Figure 1-3 Taking the flow rate calibration of a certain numerical control shot blasting machine as an example, the present invention is further described in detail:

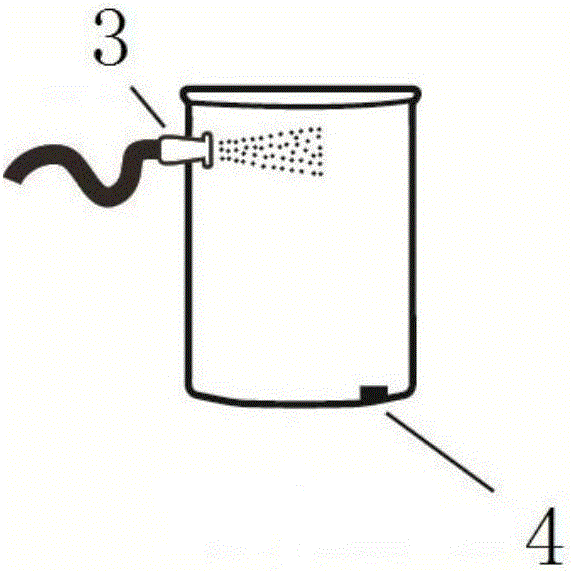

[0030] Referring to the accompanying drawings, the shot collector 1 is a sealed container, the side of the container is provided with a shot receiving port 3, which is connected to the nozzle of the numerical control shot blasting machine, and a shot discharge port 4 is provided at the bottom of the container.

[0031] 1) Select multiple measurement calibration points evenly in the entire range of the flow rate of the CNC shot blasting machine; for example, select 5 calibration points during the measurement calibration process, 2kg / min, 4kg / min, 6kg / min, 8kg / min, 10kg / min;

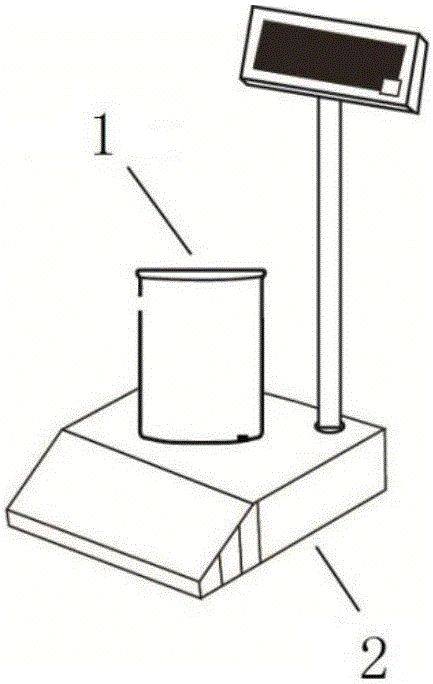

[0032] 2) Place the shot collector 1 on the electronic scale 2 prepared in advance for tare and zero reset;

[0033] 3) Take off the shot collector 1 and place it in the spray box of the CNC shot blasting machine;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com