Cleaned food automatic conveying apparatus for kitchen

An automatic feeding and cleaning technology, which is applied to kitchen utensils, cooking utensils, household utensils, etc., can solve the problems of inconvenient disassembly and maintenance, body burns, easy to be oxidized, etc. Convenience, easy disassembly and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

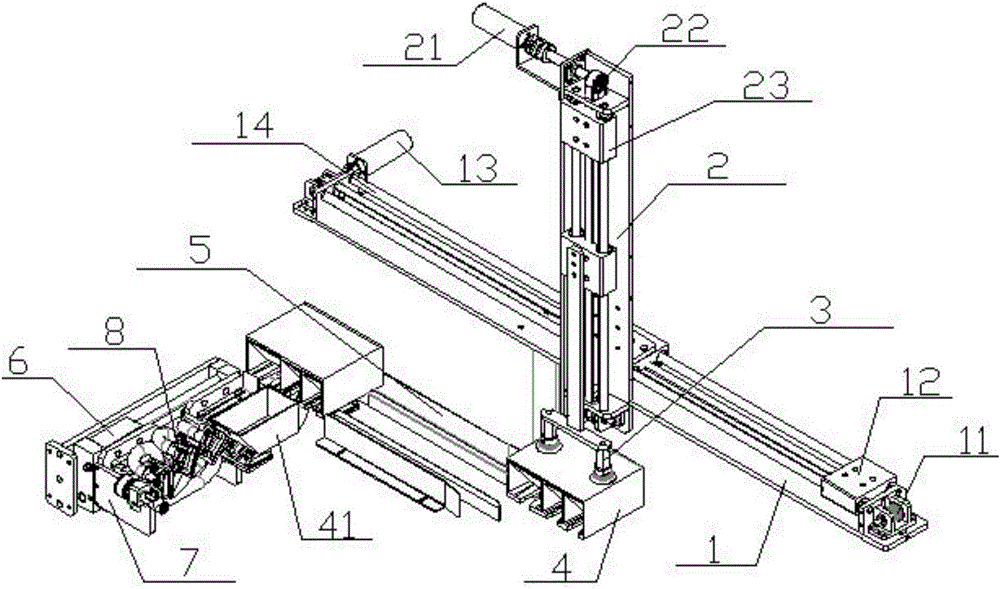

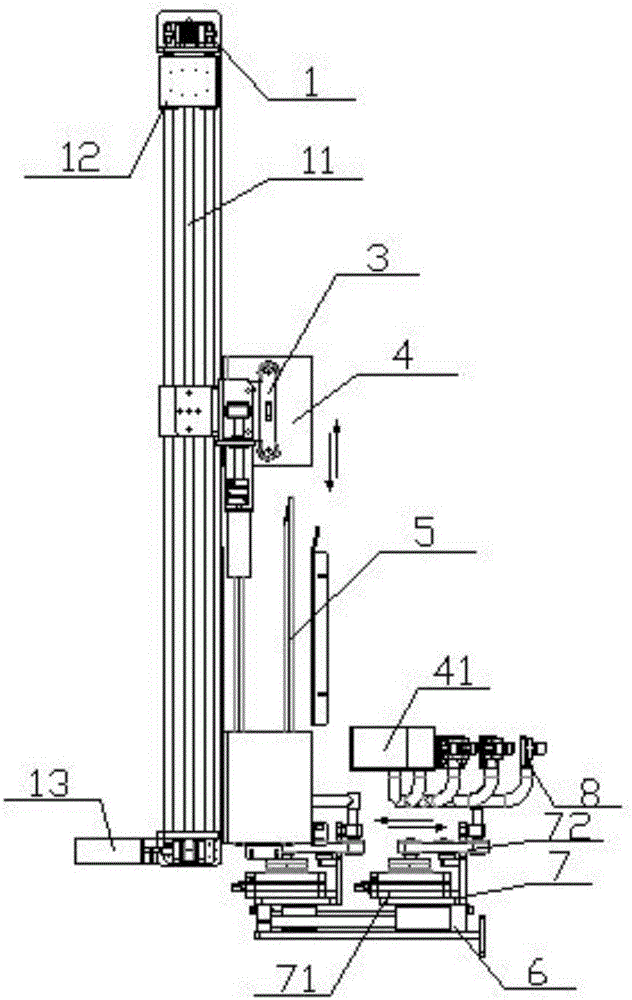

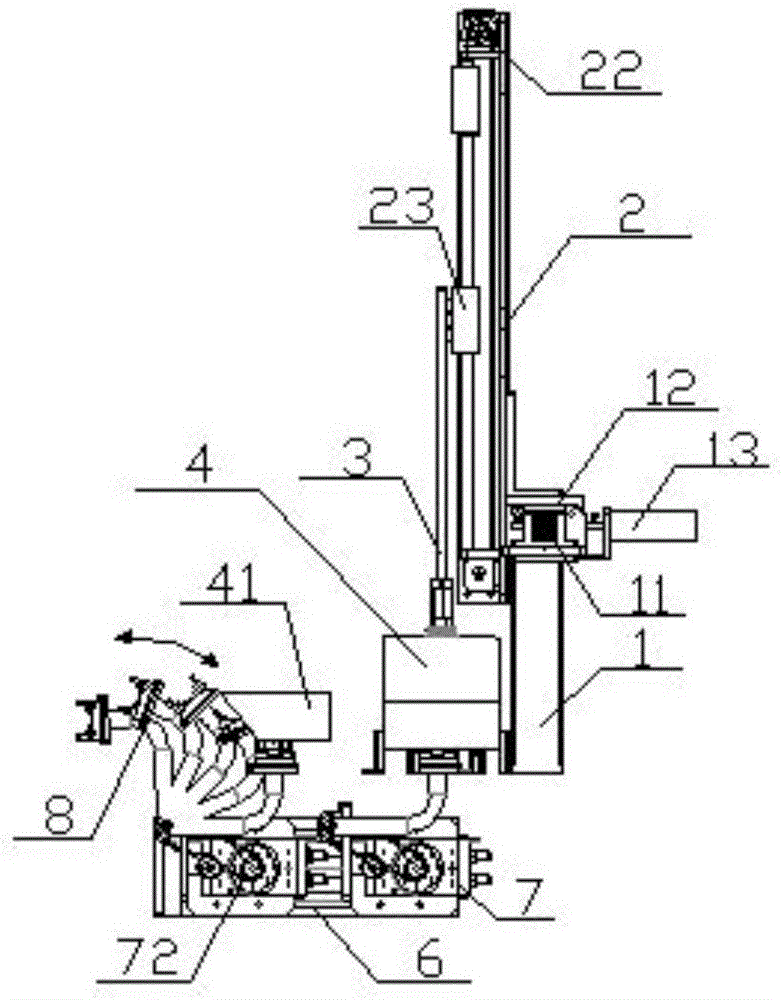

[0020] refer to figure 1 , figure 2 and image 3 , the present invention is a kitchen clean material automatic delivery device, comprising a workbench 1, a bracket 2, a clean vegetable box 4, a fixed frame 7, a hand clamping device 8, a main timing belt 11, a drive motor 13 and A plurality of slide rails 14, the output end of the drive motor 13 is connected to the pulley at one end of the main timing belt 11, and a slidable sliding sleeve 12 is installed on the slide rail 14, between the bottom of the sliding sleeve 12 and the main timing belt 11 Connected with screw fixing pieces, the top of the sliding sleeve 12 and the bracket 2 are fixedly connected with a fixed plate, and the bracket 2 is fixedly equipped with a rotating shaft motor 21, an auxiliary synchronous belt 22, a transmission shaft and several tracks, and the output of the rotating shaft motor 21 One end of the shaft and the drive shaft is connected with a coupling, and the other end of the drive shaft is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com