An automatic cutting device for steel strips used in the preparation of filter bag mouth support rings

An automatic cutting and support ring technology, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of high labor intensity, low production efficiency, danger, etc., to improve economic benefits, increase production efficiency, and reduce risks Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below through specific examples.

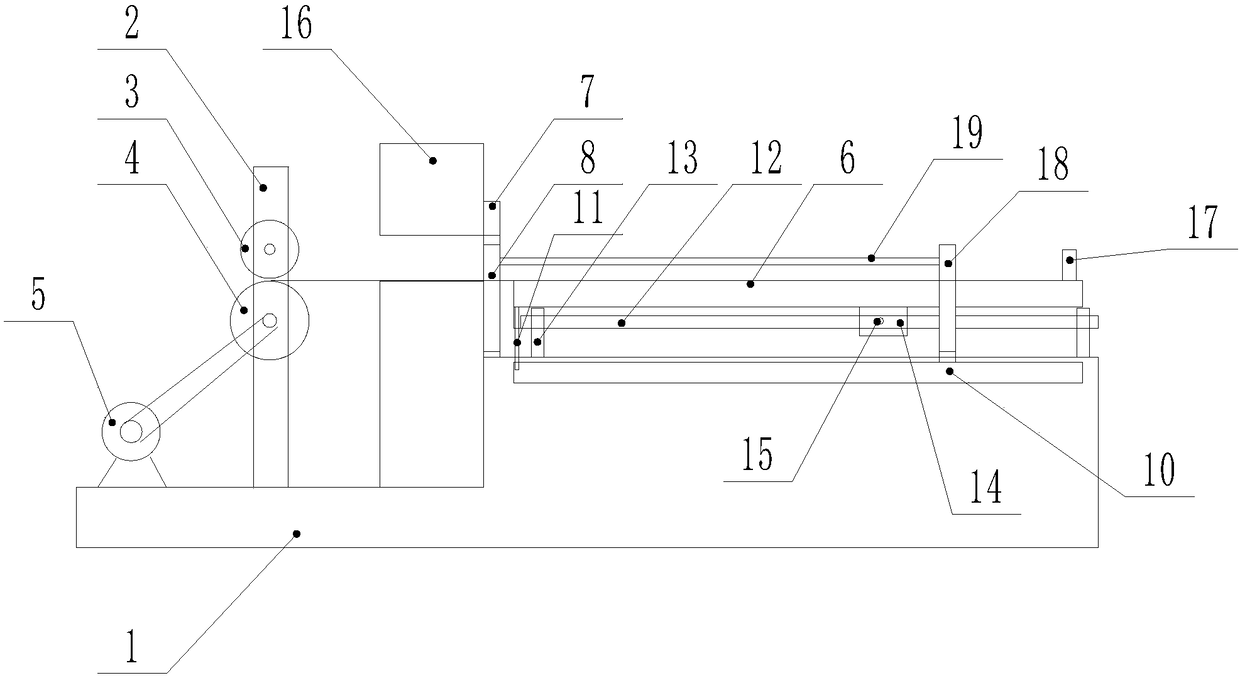

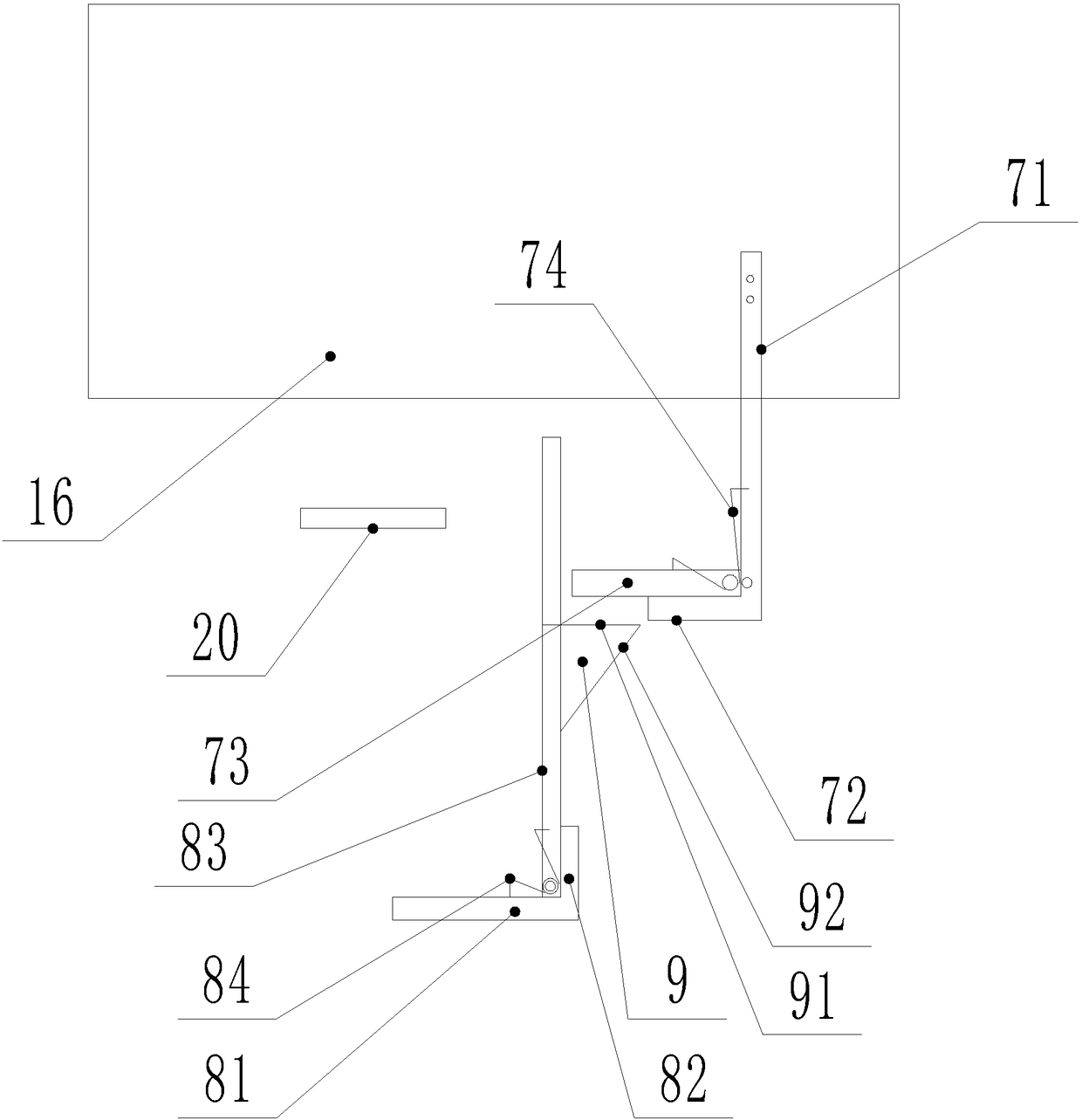

[0027] Such as figure 1 , 2 As shown, a steel strip automatic cutting device for the preparation of a filter bag mouth support ring includes a frame 1, and a feeding mechanism, a punch 16, a discharging mechanism, and a loading mechanism are sequentially installed on the frame 1. The mechanism includes a loading frame 2, on which a pressure roller 3 and a feeding roller 4 are rotated, and the feeding roller 4 is driven by a driving device; the loading mechanism includes a loading platform 6, and the loading platform 6 Installed on the frame 1, a micro switch 17 is also installed on the loading platform 6; the unloading mechanism includes an auxiliary unloading rack 7 and an unloading rack 8, and the auxiliary unloading rack 7 is fixed on the punch of the punch press 16 , the unloading frame 8 is installed on the frame 1, the auxiliary unloading frame 7 includes a first fixing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com