Magnetic type flexible track for automatic welding of ship body surface

An automatic welding and flexible track technology, applied in the field of flexible track, can solve problems such as complicated operation, and achieve the effect of simple splicing operation, ensuring flexibility, and high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

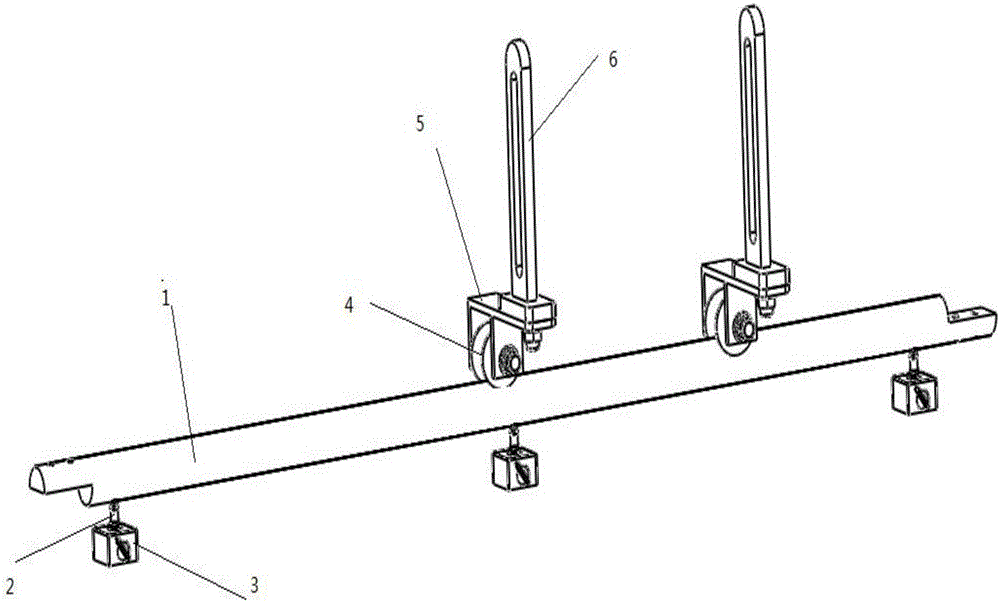

[0016] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

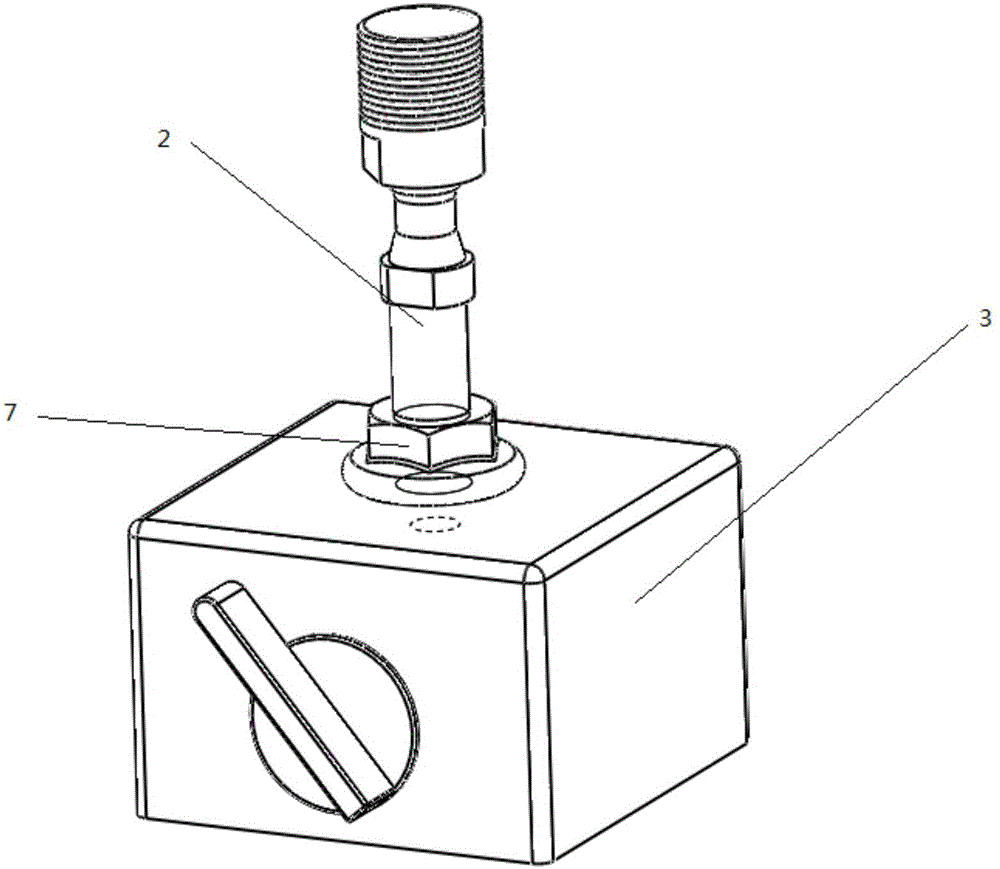

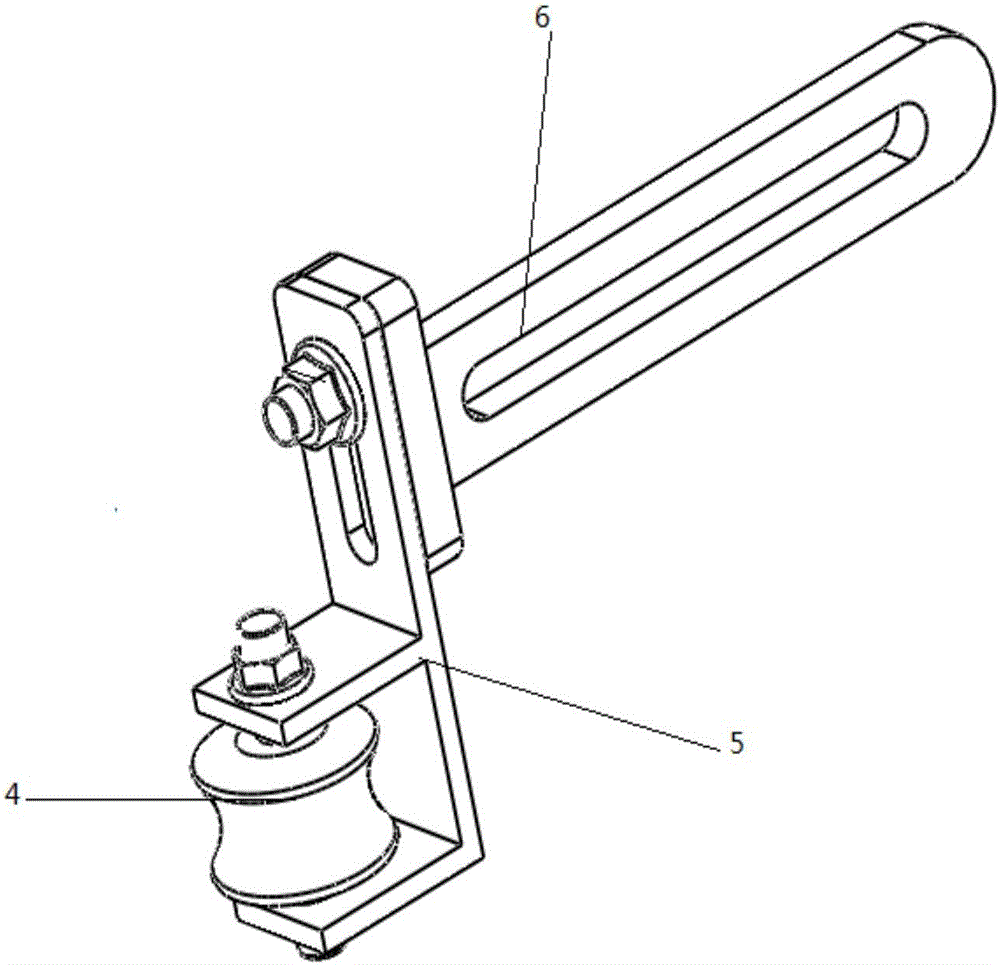

[0017] As shown in the accompanying drawings, a magnetic suction type flexible track for the automatic welding of the hull surface of the present invention includes a plurality of magnetic seat modules arranged in parallel and spaced front and back, each of the magnetic seat modules includes a magnetic seat 3, and A ball joint bearing 2 is installed above each said magnetic base 3, and one end of said ball joint bearing 2 is threadedly connected with the magnetic base 3 and the two are fixed by the adjusting nut 7, and the magnet is adjusted by the adjusting nut 7. The position of the seat 3, the other end of the ball joint bearing 2 is screwed to the bottom of the main body track 1, which is convenient for disassembly. The magnetic base 3 is preferably an existing switch type magnet base on the market, through which the magnet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com