Weldment stacking rack with lifting function

A technology of welding parts and functions, applied in the field of welding parts stacking racks, can solve problems such as safety accidents, operator's finger rolling, increasing the difficulty of the operator's work, etc., to reduce work intensity, facilitate transfer, and save manpower Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

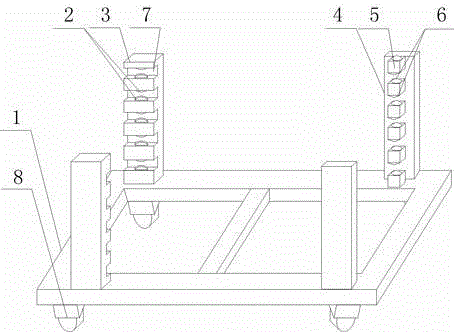

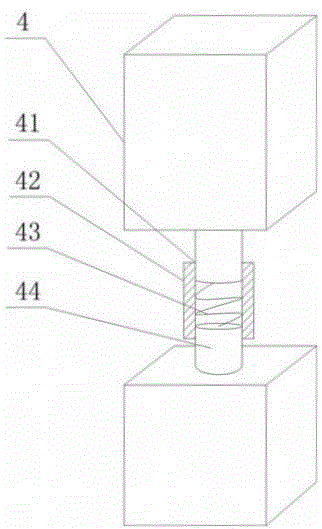

[0020] Such as figure 1 with figure 2 As shown, the present embodiment includes a rectangular support frame 1, on the two long sides of the support frame 1, a column A3 and a column B4 are respectively arranged at intervals, and a plurality of columns connected with the A rectangular groove 7 parallel to the long side of the support frame 1, and a semispherical movable cavity is respectively arranged on the two side walls of the middle part of the rectangular groove 7, and the cam 2 is rotated and arranged in the movable cavity, and the part of the cam 2 protrudes Placed in the rectangular groove 7; on the inner side wall of the column B4, a plurality of protrusions 5 on the same vertical line are arranged at equidistant intervals, and balls 6 are rotated on the upper and lower ends of the protrusion 5, and the Column B4 is made of support end and adjustment end, and support end is fixed on the long side of support frame 1, and the upper end surface of support end is fixed w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com