Temperature partitioned type refrigerator and standard refrigerator system

A technology of temperature partition and cold box, applied in thermal insulation containers, household refrigeration devices, containers, etc., can solve the problems of large extrusion loss, increased cargo loss, large energy consumption, etc., to meet temperature control requirements and improve structural strength. , to avoid the effect of accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0086] To achieve the above object, the present invention adopts the following technical solutions:

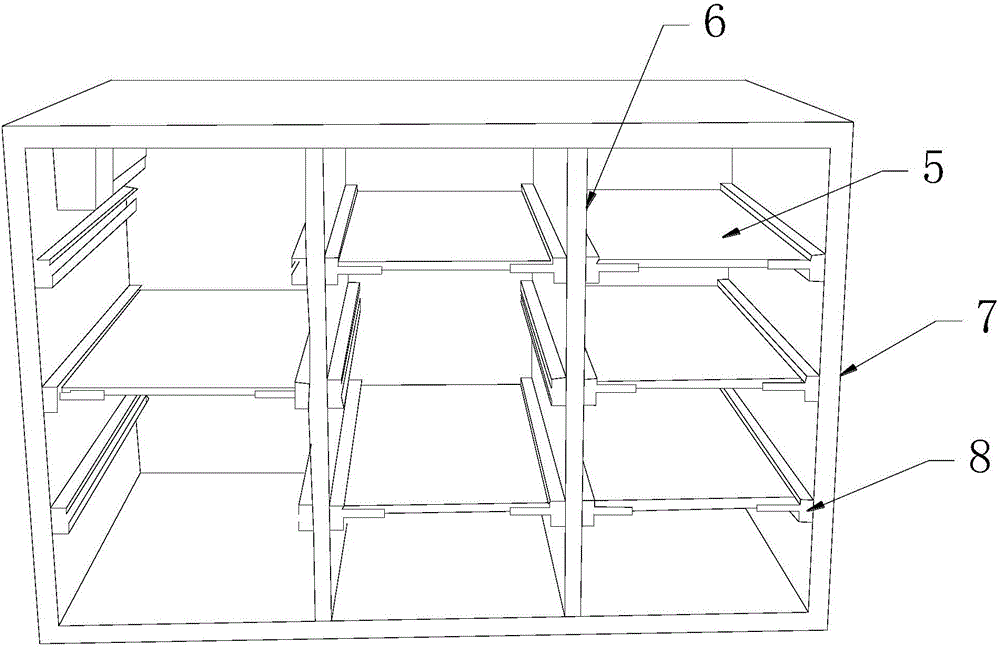

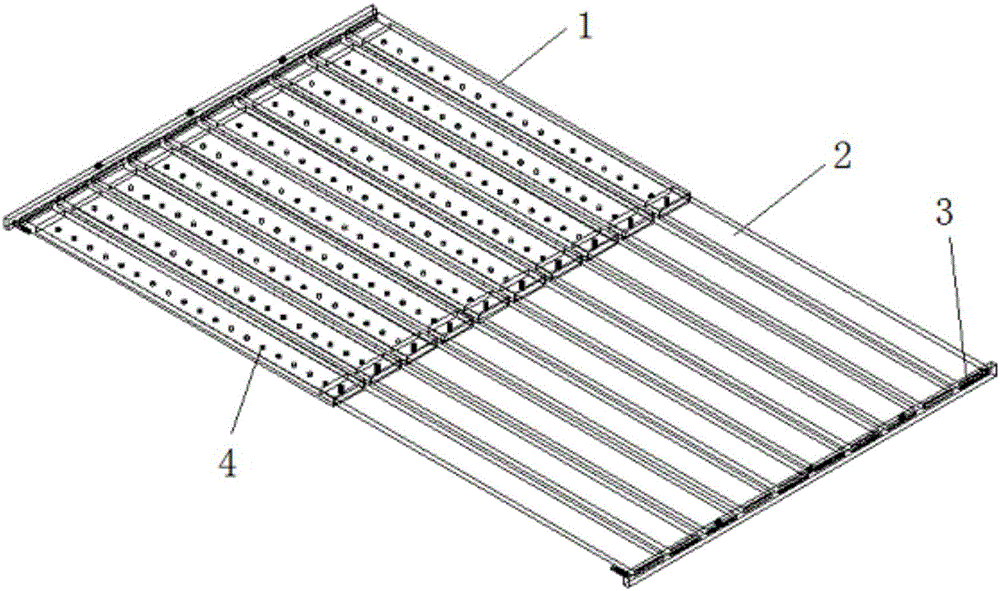

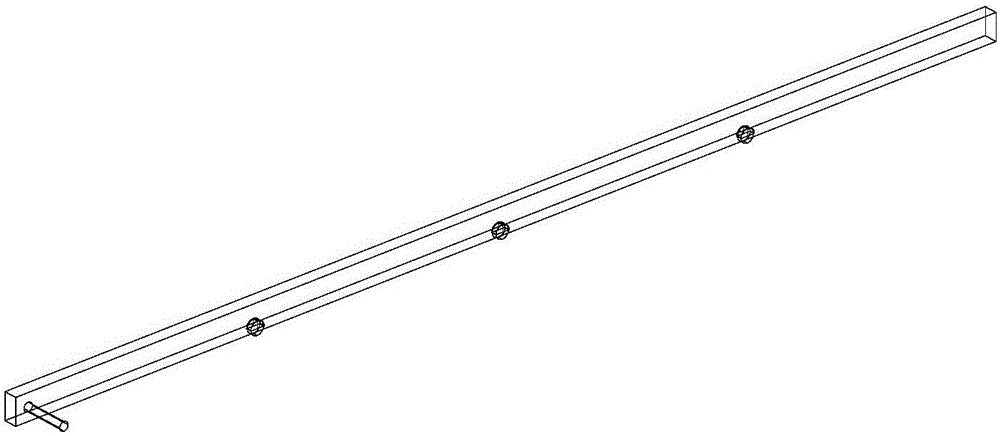

[0087] Such as figure 1 and figure 2 As shown, a kind of temperature zoning type cold box includes a box body 7 and a telescopic pull-out shelf, and the telescopic pull-out shelf is installed inside the box body 7; wherein, the telescopic pull-out shelf 7 includes at least two vertically arranged The heat insulating plate 6, the upper end and the lower end of the heat insulating plate 6 are against the top inner wall and the bottom inner wall of the box body 7 respectively, and a moving structure is arranged between the temperature insulating plate 6 and the top inner wall and the bottom inner wall of the box body 7, so that The heat insulating plate 6 can move laterally in the box body 7;

[0088] Both sides of the insulation board 6 are provided with at least one shelf chute 8, and at least one shelf chute 8 is also provided on the two side walls of the box body 7 near th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com