Process for bonding carbon-fiber components of light rail vehicles

A carbon fiber and component technology, which is applied in the field of light rail vehicle carbon fiber component bonding technology, can solve the problem of inability to produce carbon fiber light rail train vehicle body and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

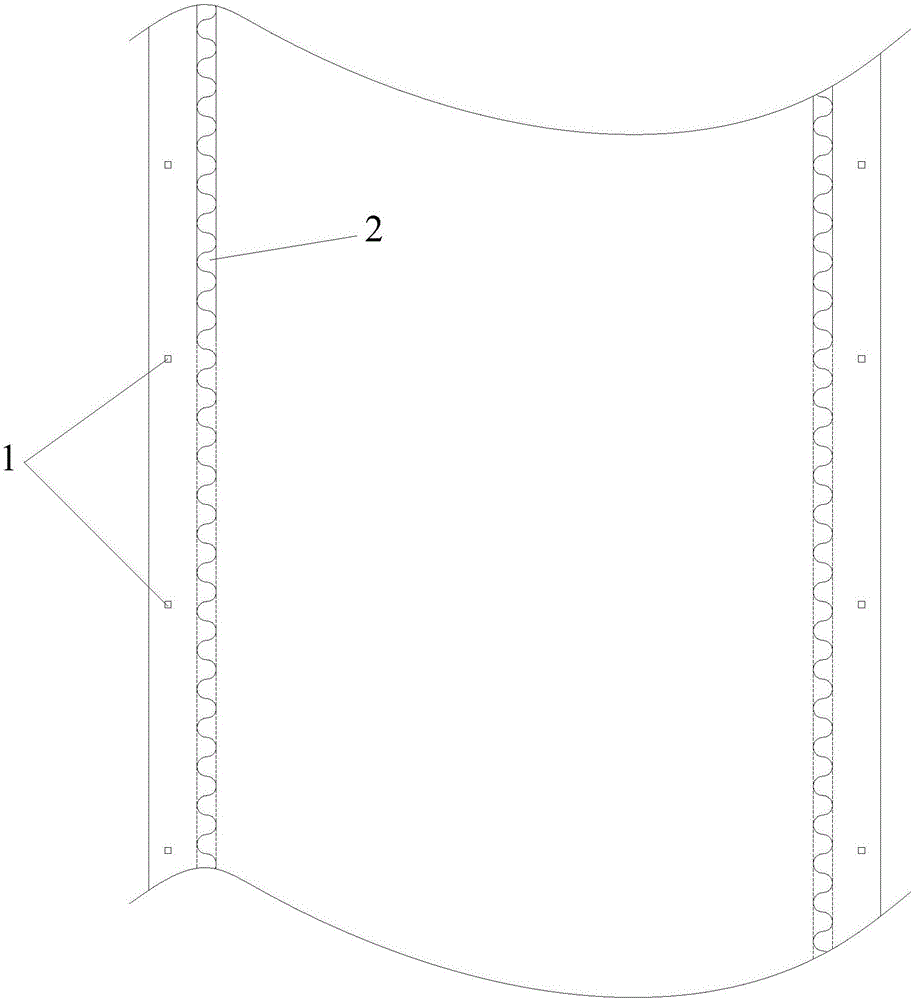

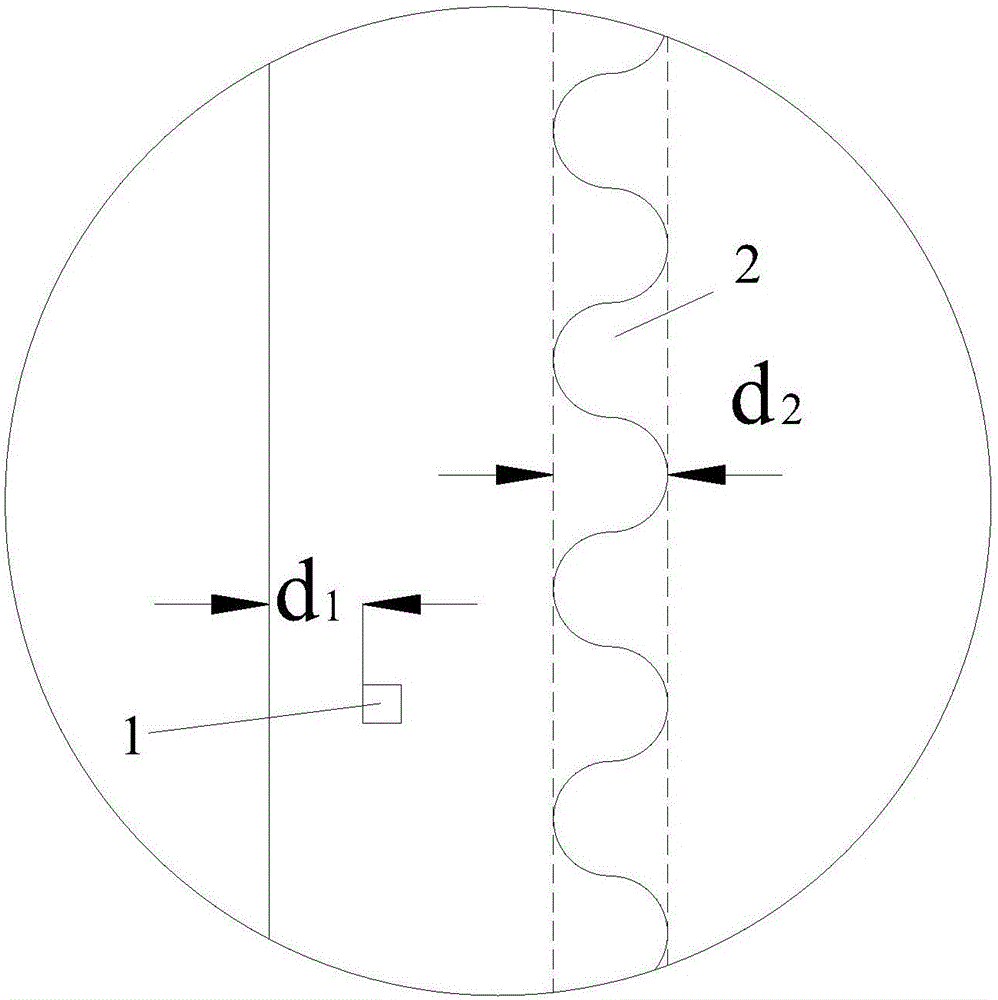

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0023] Such as Figure 1 to Figure 2 Shown, light rail car carbon fiber part bonding process of the present invention comprises the steps:

[0024] Step 1: Select a stable construction environment with an ambient temperature range of 15°C to 30°C and a relative humidity range of 30% to 70%;

[0025] Step 2: Grind the surface of the bonded end face to be assembled on the carbon fiber component: use No. 240 sandpaper to cross-grind along the grinding direction at an angle of ± 45° to the extending direction of the bonded end face;

[0026] Step 3: Use a primer to evenly coat the bonded end faces of the carbon fiber parts after grinding in step 2;

[0027] Step 4: Use the 1-A-05-4-H6-Ts type industrial rubber sheet to make multiple glue thickness positioning blocks 1, the length and width of the positioning block 1 are both 10 mm, and the thickness is 5 mm;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com