Intelligent needle measuring instrument mechanism for circular knitting machine

A technology of circular knitting machine and needle measuring instrument, which is applied in knitting, textiles and papermaking, etc. It can solve problems such as broken needles, waste of production raw materials, and affecting the production progress of enterprises, and achieves accurate alignment, fast operation, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

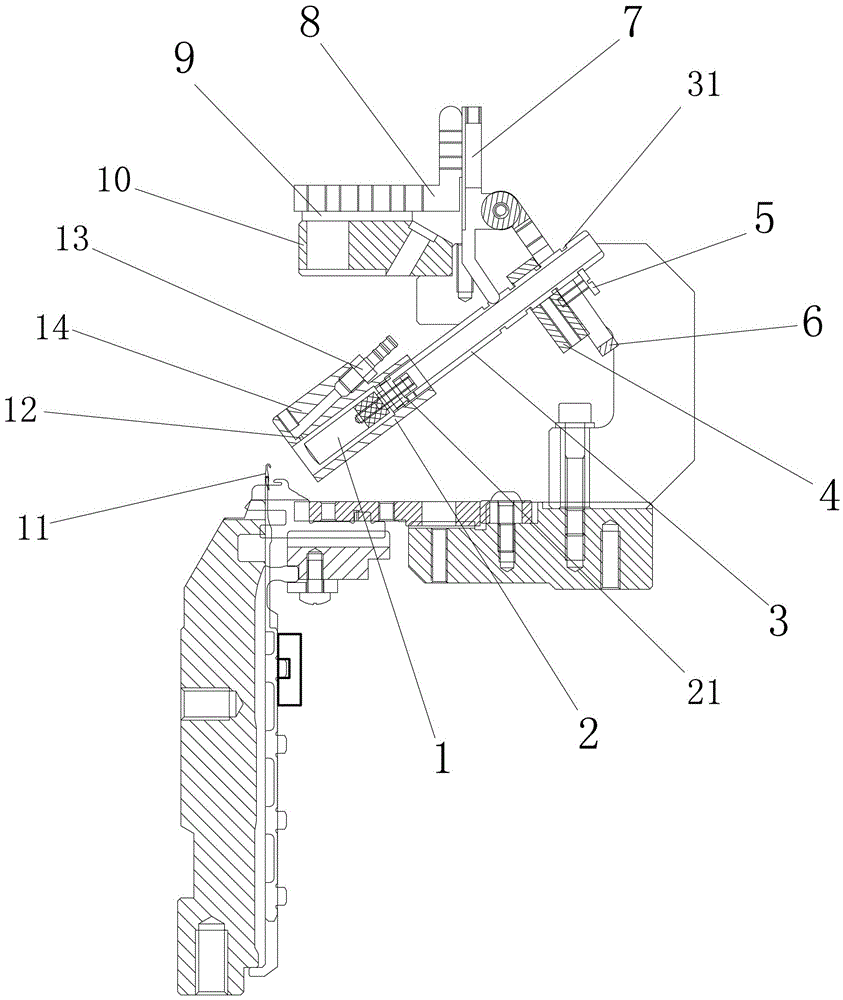

[0013] Such as figure 1 As shown, a circular knitting machine intelligent needle detector mechanism, including intelligent probe 1, intelligent probe 1 is located in the probe holder 2; the lens of intelligent probe 1 is facing the needle hook of knitting needle 11; intelligent probe 1 and The control system is connected; the probe holder 2 is connected to one end of the cylinder body 3; the other end of the cylinder body 3 is connected to a square seat 4; the square seat 4 is set on the angle rod 6 through the adjustment screw 5; the angle rod 6 is set On the lifting seat 7; the angle rod 6 can swing relative to the lifting seat 7; the lifting seat 7 is arranged on the fixed seat 8; Set on the yarn feeding ring 10 of the circular knitting machine.

[0014] The inner wall of the other end of the probe fixing seat 2 of the present invention is provided with a hollow groove 21; the hollow groove 21 communicates with the inner hole of the cylinder body 3, which is beneficial to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com