Processing technique of host machine frame of wall plastering machine and host machine frame of wall plastering machine

A processing technology, the technology of plastering machine, applied in the direction of construction, building structure, etc., can solve the problem of the wall not reaching the ideal effect, and achieve the effect of improving the quality of the plastering wall, improving the installation efficiency and reducing the labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

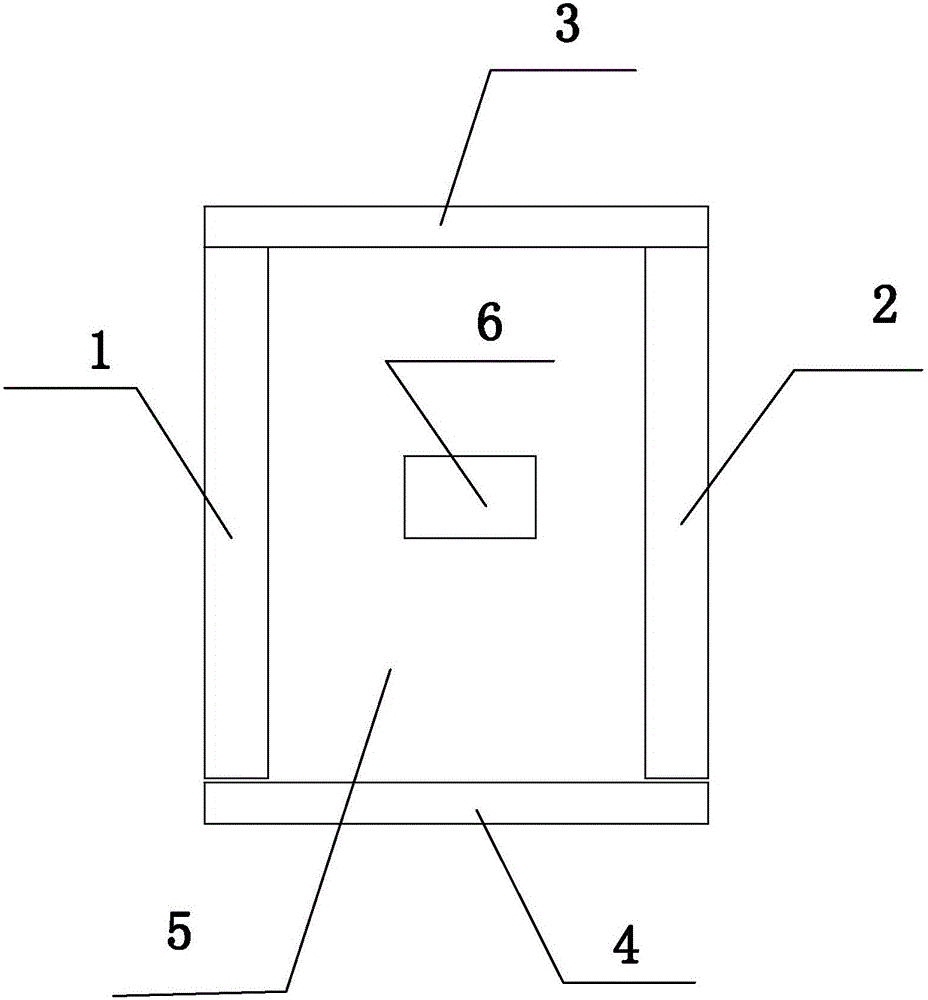

Image

Examples

Embodiment Construction

[0016] The processing technology of the main body frame of the wall plastering machine of the present invention is as follows: first, the plastering bracket and the roller box panel are integrally formed into side panels by laser cutting, and the front panel, rear panel, bottom panel and motor are installed The board is cut by laser;

[0017] Second, bend the side plate sheet metal;

[0018] Thirdly, the four side plates processed in the second step are spliced into two symmetrical roller boxes through the roller box connecting plate;

[0019] Fourth, the left and right roller boxes are detachably connected through the front panel, rear panel and bottom panel. The left and right roller boxes are symmetrically installed on the left and right ends of the front panel, rear panel and bottom panel. on the bottom plate.

[0020] The main body frame of the wall plastering machine made according to the processing technology of the main body frame of the wall plastering machine inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com