Method for relieving harms of high partial load pressure pulsation of mixed-flow water turbine

A load pressure and water turbine technology, applied in the directions of hydropower generation, machine/engine, reaction engine, etc., can solve the problems of large pressure pulsation in hydropower stations, endangering the safety of unit operation, and inability to popularize turbines and other power stations, etc., and achieve strong pertinence. , lighten the effect of order and simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0015] The present invention proposes a method for mitigating the hazards of high partial load pressure pulsation of a Francis turbine, which includes the optimization of the following two aspects of the turbine:

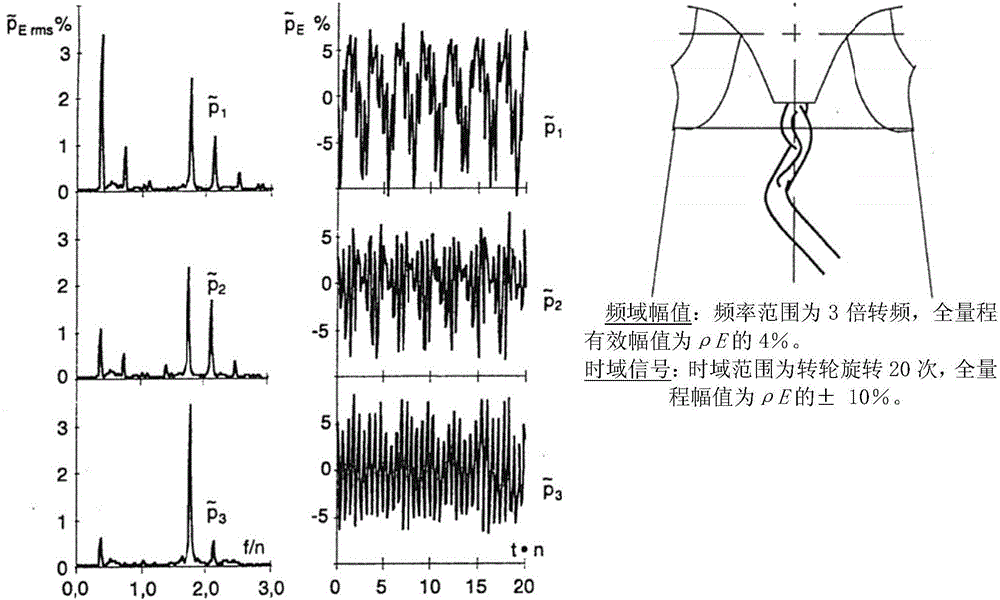

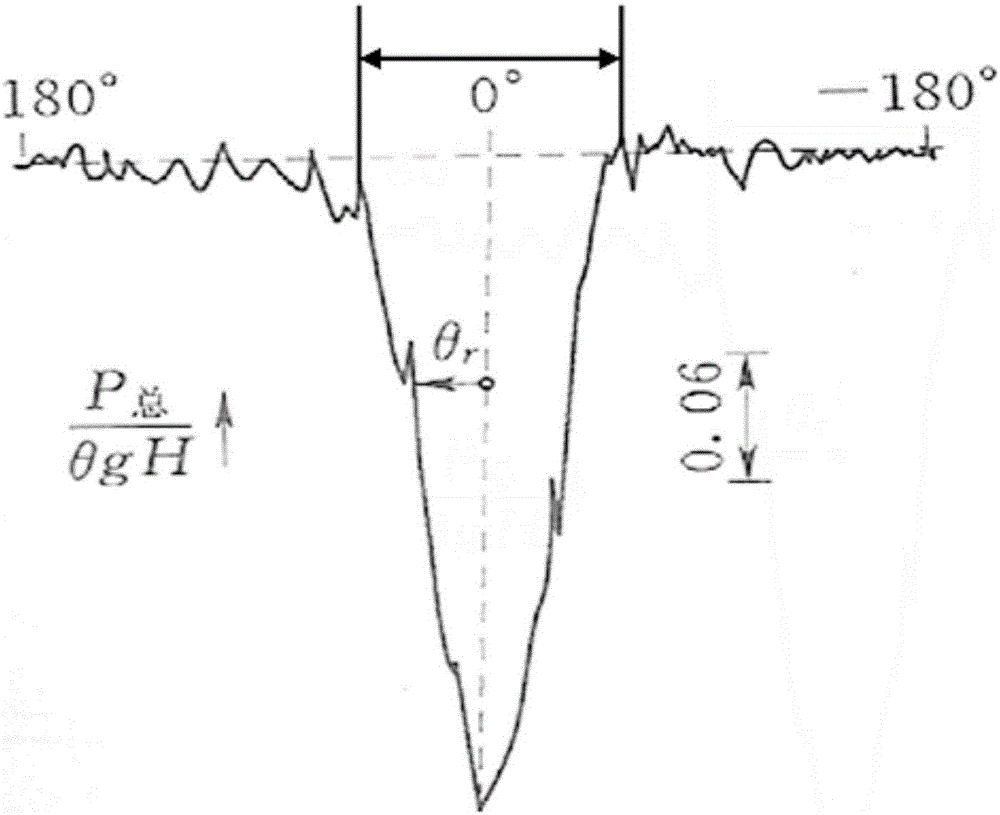

[0016] 1) Reduce the angle between the outlet edge 5 of the runner blade 2 near the upper crown 1 and the horizontal plane from the existing 10° to 25° to 8° to 20°, so as to reduce the inner side of the runner blade 2 ( close to the upper crown 1) outlet flow circulation, and then reduce the draft tube free vortex initial radius d 0 (which is image 3 The initial circulation at the horizontal distance of the pressure sharp turn on both sides shown above) can reduce the size of the vortex cavity, reduce the expansion-contraction range of the string-like vortex strands in the vortex, and reduce the high part Load pressure pulsation.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com