Continuous calcium carbide furnace discharging collecting and unloading system

A continuous calcium carbide furnace technology, applied in furnaces, furnace components, charge manipulation, etc., can solve the problems of excessive calcium carbide volume, broken, unreasonable design, etc., and achieve the effects of improving production efficiency, avoiding waste, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

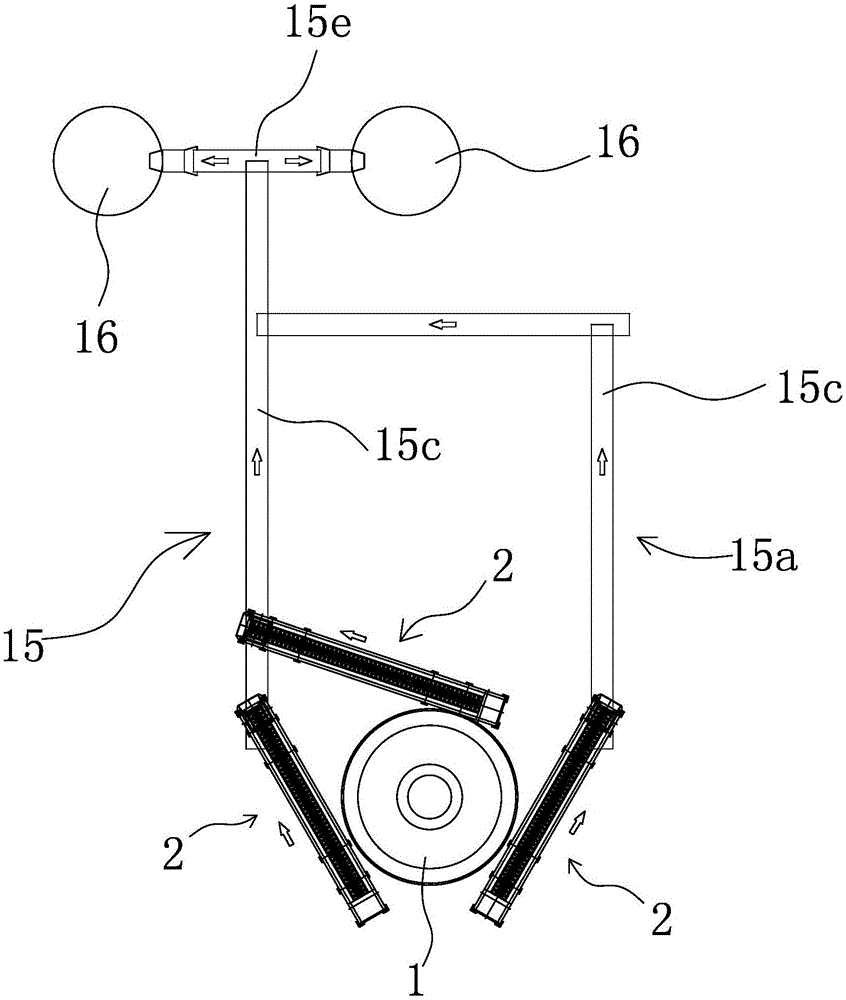

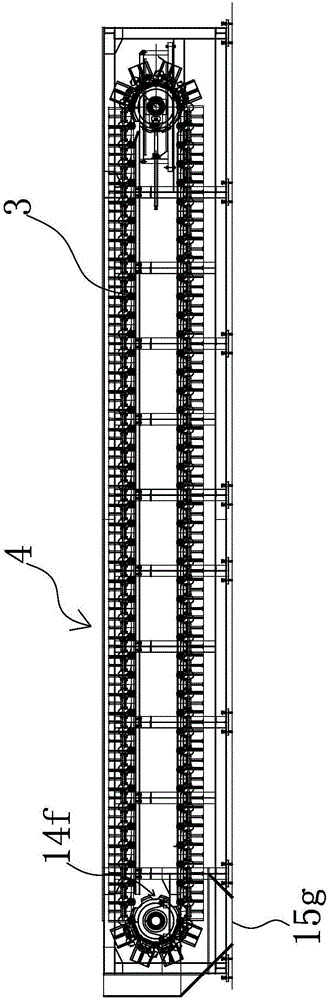

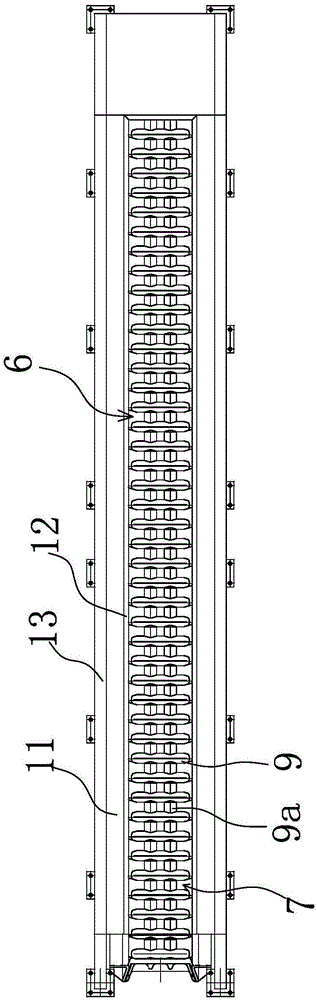

[0030] Such as Figure 1-10 As shown, the continuous calcium carbide discharge collection and unloading system includes a calcium carbide furnace 1. At least one calcium carbide outlet 1a is provided on the calcium carbide furnace 1, and the position corresponding to the calcium carbide outlet 1a is provided with a molten state that can discharge the calcium carbide outlet 1a. The calcium carbide is collected and transported to a set position and the collected calcium carbide is discharged to the continuous calcium carbide collecting and forming mechanism 2 at the set position.

[0031] In this application, the molten calcium carbide discharged from the calcium carbide outlet 1a is directly cast on the continuous calcium carbide collecting and forming mechanism 42, and is cooled to form a block during the transportation of the molten ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com