Method for measuring tunnel linear exposed structural surface based on three-dimensional laser scanning technique

A technology of three-dimensional laser and scanning technology, applied in the field of linear exposed structural surface measurement technology, can solve the problems of long working cycle, bottleneck of three-dimensional laser scanning technology, difficult to use, etc., and achieve the effect of efficient acquisition and saving lighting equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with drawings and embodiments.

[0028] The invention provides a method for measuring the linear exposed structural surface of a tunnel based on three-dimensional laser scanning technology, which includes the following steps:

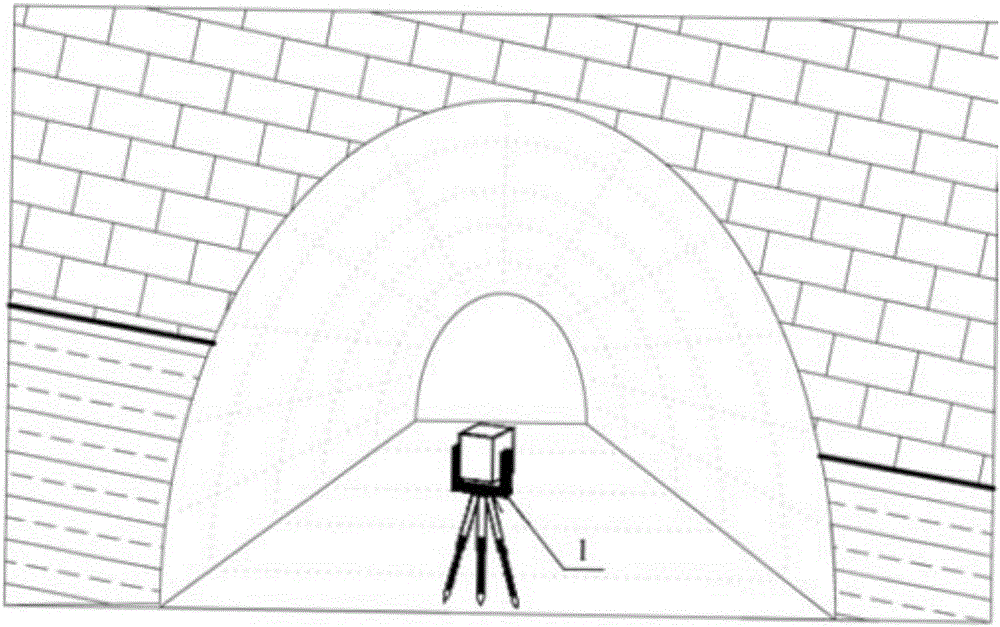

[0029] (1) Refer to figure 1 , use the 3D laser scanner 1 to collect point cloud data inside the tunnel, the point cloud data includes the position information and color information of the points on the tunnel wall; cloud collection;

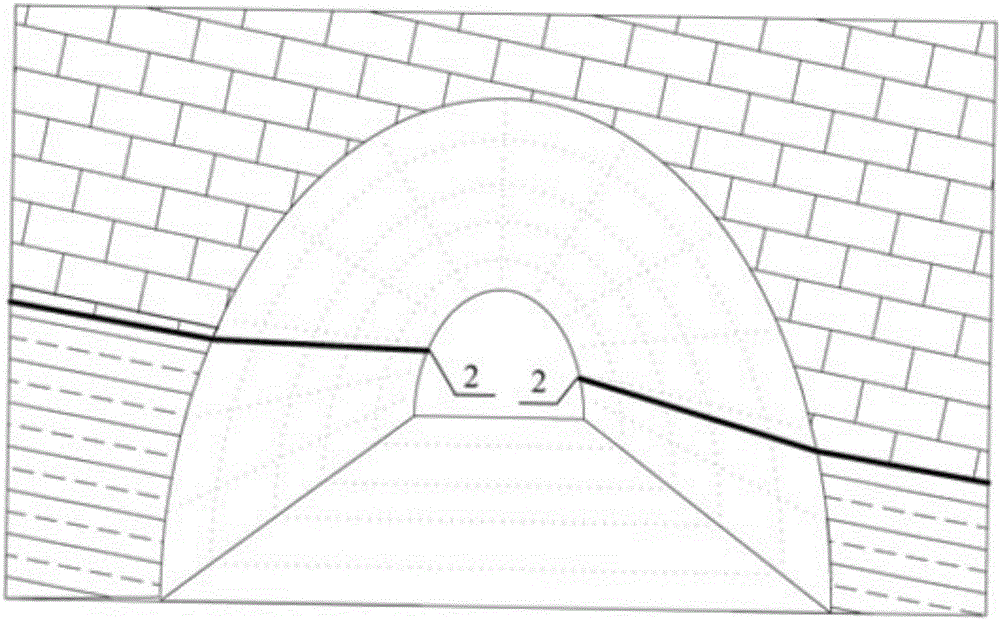

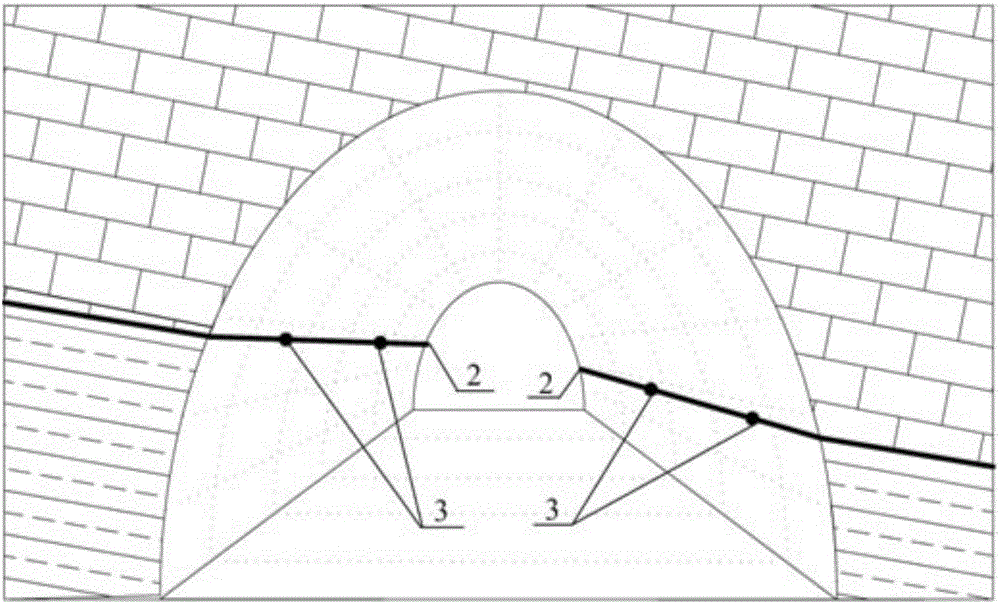

[0030] (2) Use the collected point cloud data to determine the potential structural surface lines: refer to figure 2 , input the collected point cloud data into the computer, use the collected point cloud data in the computer to reproduce the geological environment of the tunnel wall, realize 3D real scene replication, combine the sensitivity and color information of the laser reflection during point cloud collection, and preliminarily judge th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com