Stacking forming funnel for test of oxidation combustion characteristics of solid dangerous goods

A technology of combustion characteristics and dangerous goods, which is applied in the direction of using combustion for chemical analysis to achieve the effects of ensuring consistency, avoiding inconsistency, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solution of the present invention will be described in further non-limiting detail below in conjunction with the accompanying drawings.

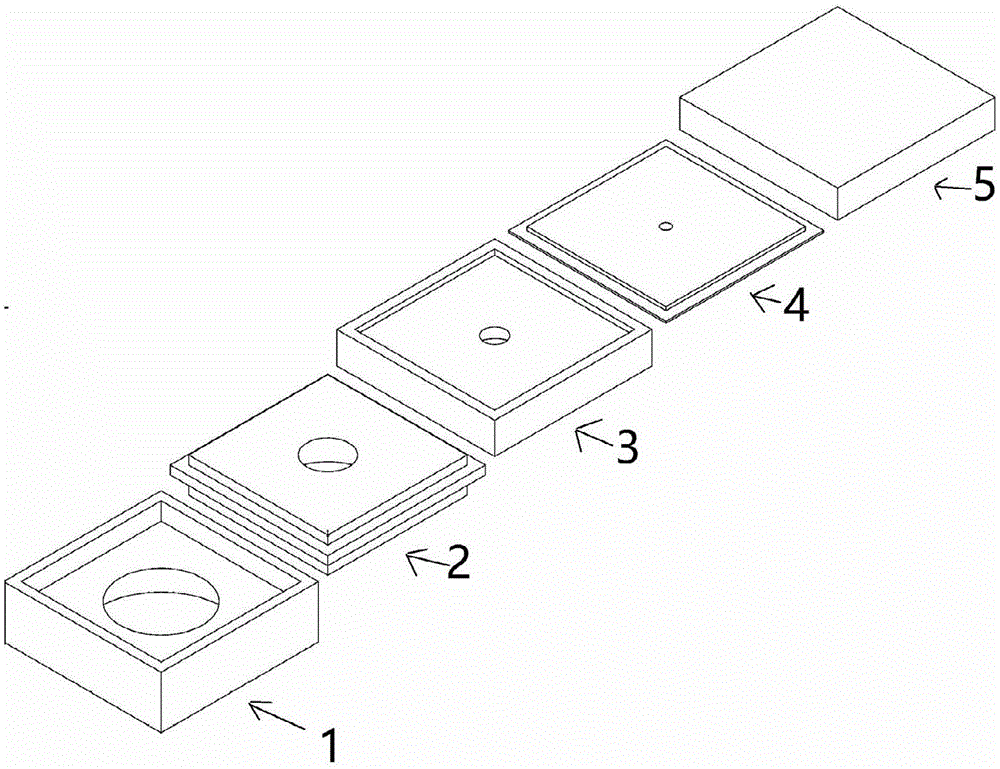

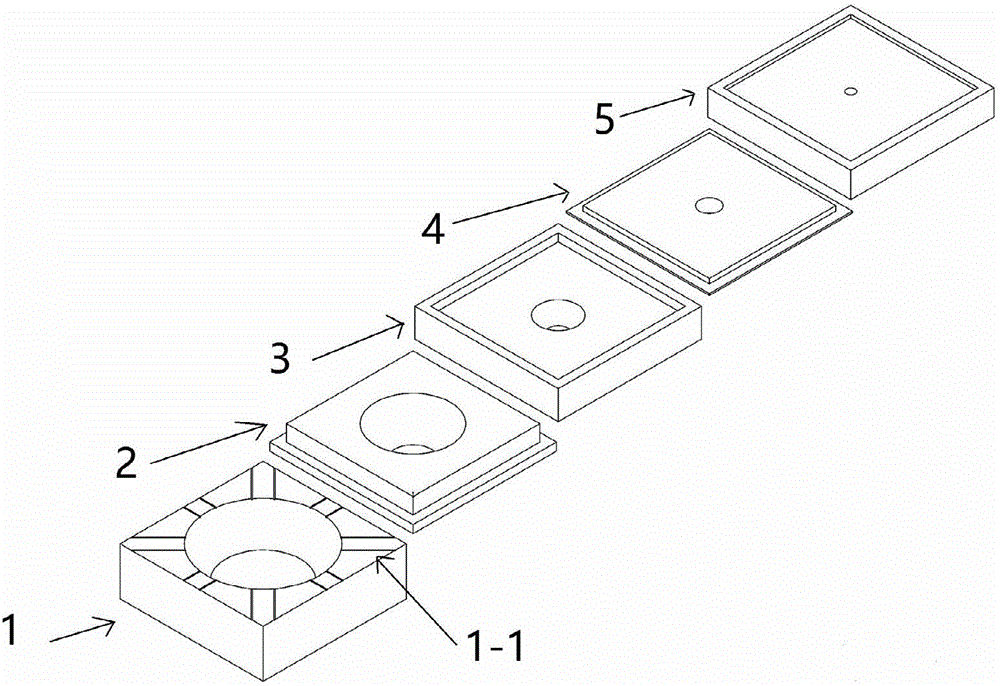

[0024] Such as figure 1 — Figure 4 Shown, the present invention is used for the stacking molding funnel of solid dangerous goods oxidative combustion characteristic test to be made up of the first layer module 1, the second layer module 2, the third layer module 3, the fourth layer module 4 and the fifth layer module 5, and is formed by nesting and stacking in sequence from bottom to top. The central parts of the first layer module 1, the second layer module 2, the third layer module 3 and the fourth layer module 4 are all provided with conical through holes. And the frustum-shaped through-holes are arranged from bottom to top according to large to small, and the center part of the fifth layer module 5 at the top is provided with a conical counterbore, and the conical counterbore is connected with all the conical-shape...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com