Method and system for adjusting optical uniformity of liquid crystal modules

An optical uniformity, liquid crystal module technology, applied in optics, nonlinear optics, instruments, etc., can solve the problems of light intensity difference of surface light source, poor optical uniformity of liquid crystal display, etc., and achieve the effect of improving optical uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0060] The invention provides a method for adjusting the optical uniformity of a liquid crystal module.

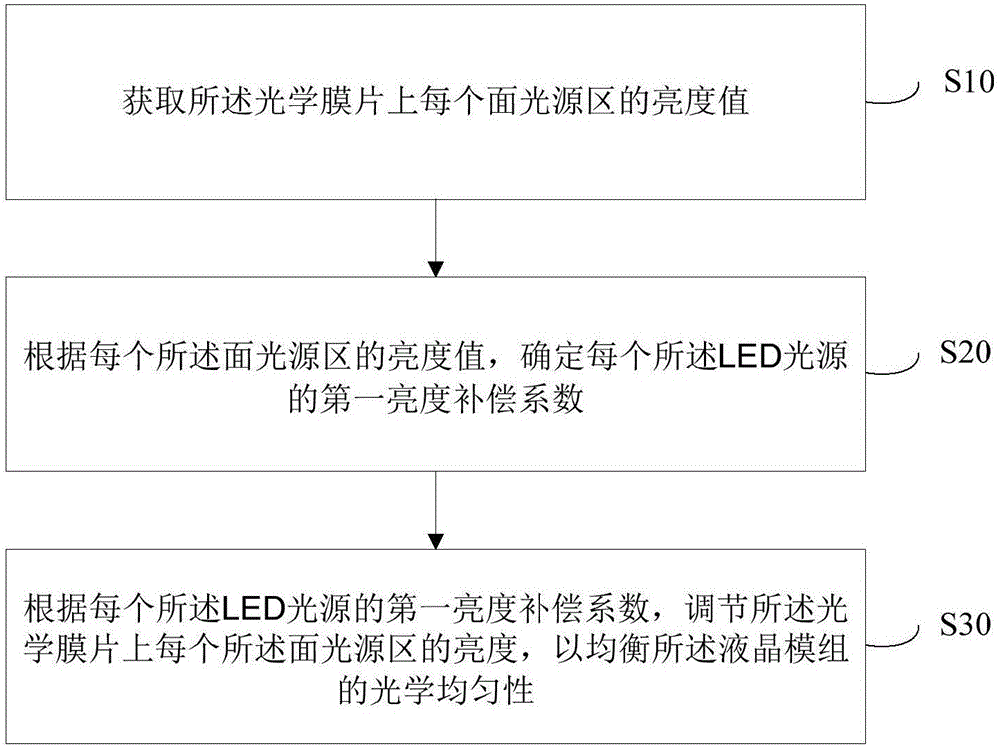

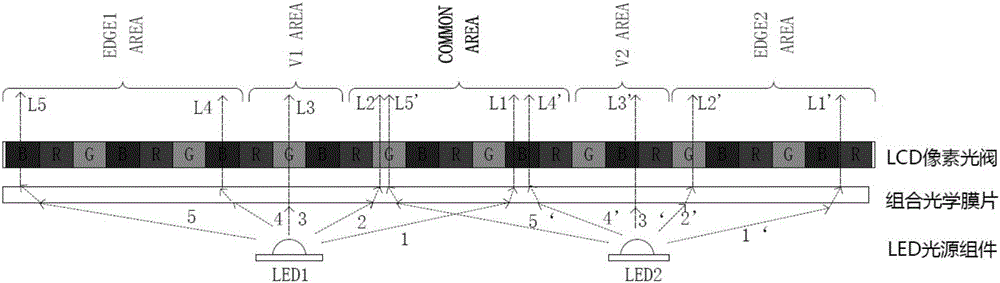

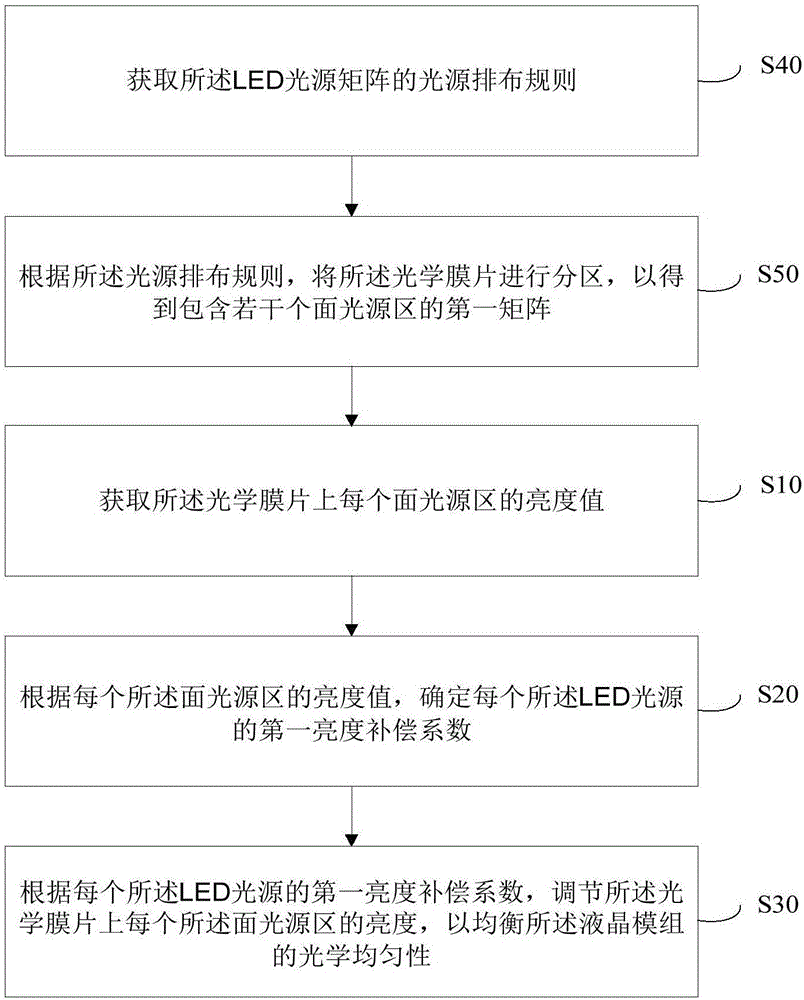

[0061] see figure 1 , in order to achieve the above object, the first embodiment of the present invention provides a method for adjusting the optical uniformity of a liquid crystal module, the liquid crystal module includes an LED light source matrix and an optical film arranged facing each other, and the optical film is arranged on the optical film The liquid crystal display on the side of the sheet away from the LED light source matrix, the side of the optical film away from the LED light source matrix is the light output side, and the method for adjusting the optical uniformity of the liquid crystal module includes the following steps:

[0062] Step S10, acquiring the luminance value of each surface light so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com