Fire simulation experimental system for industrial production line

A simulation experiment and production line technology, which is applied in the field of fire simulation experiment system, can solve the problems of inability to accurately determine the ignition point and inability to accurately simulate the flow of high-temperature flue gas, etc., to achieve the effect of improving sensitivity and accuracy, and improving the degree of realism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

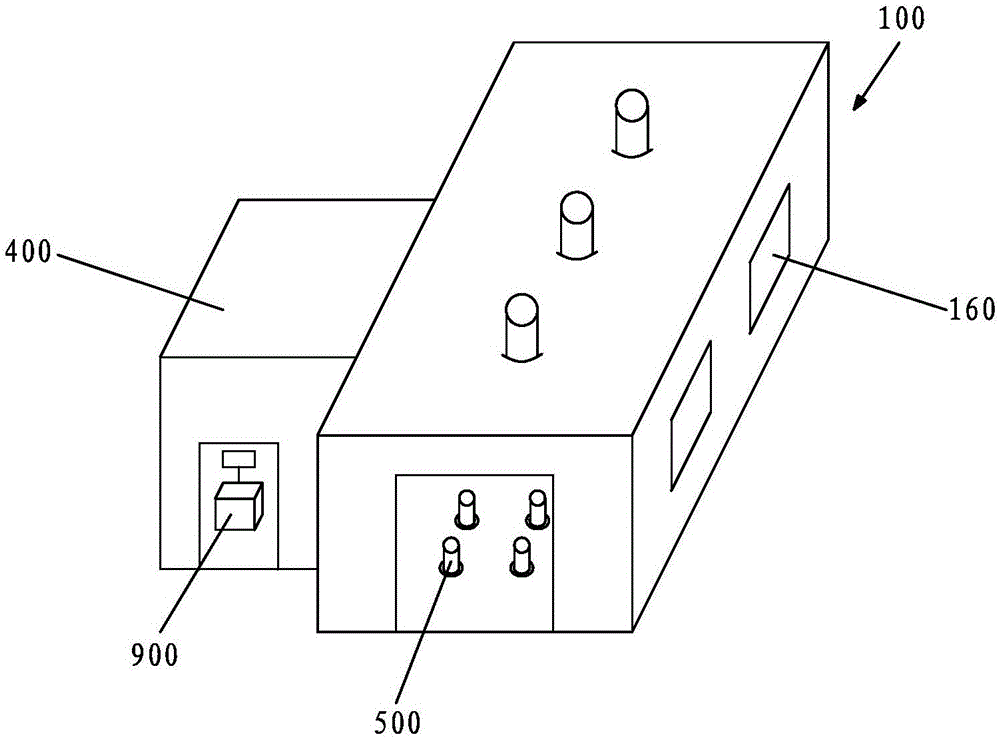

[0032] Please refer to figure 1 , according to a non-limiting embodiment of the present invention, an industrial production line fire simulation experiment system is provided, including: a fire simulation room 100, an industrial production line simulation device (described in detail below) arranged in the fire simulation room 100, a The smoke temperature measurement subsystem (detailed below), the smoke composition measurement subsystem (detailed below) and the smoke velocity measurement subsystem (detailed below) inside the fire simulation chamber 100, adjacent to the side of the fire simulation chamber 100 The installed control room 400 and the control platform 900 installed inside the control room 400 .

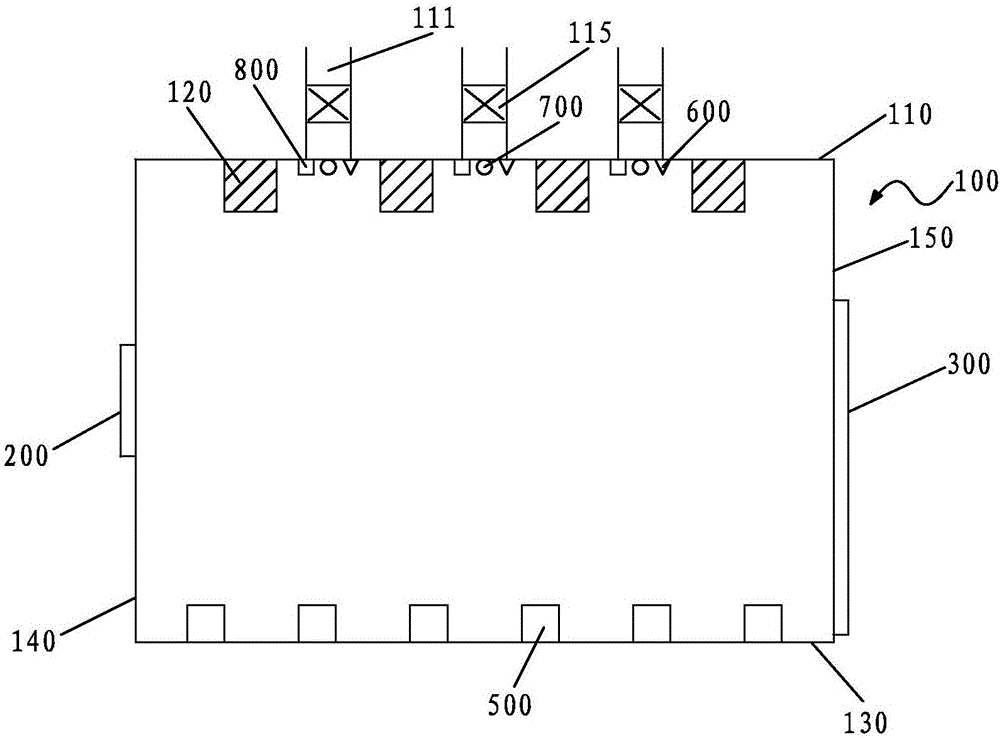

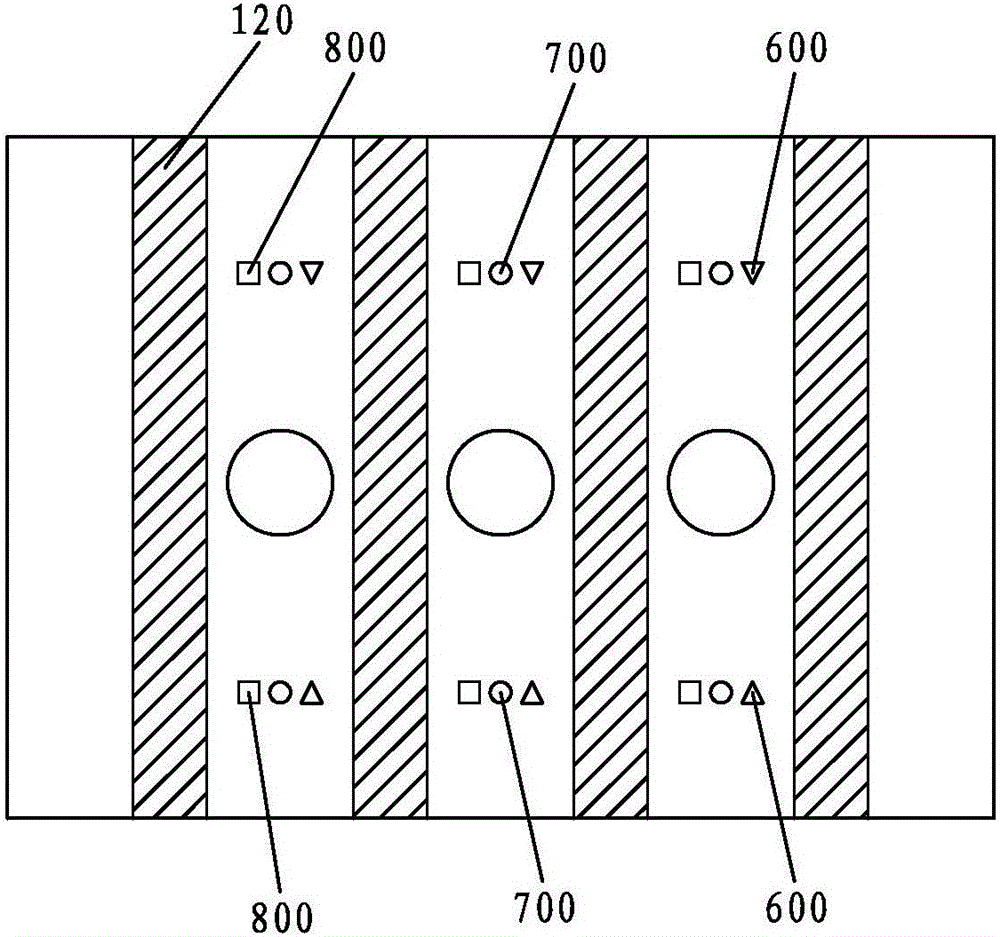

[0033] Please refer to figure 2 , the fire simulation room 100 includes a top wall 110, a bottom wall 130, two end walls 140, 150 and two side walls (not numbered). Four beams 120 are suspended at equal intervals on the top wall 110 of the fire simulation room 100 , and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com