Thimble assembly of in-core instrument for nuclear power station

A core instrument and nuclear power plant technology, applied in the field of core nuclear measurement instrument, can solve the problems of short life, scattered interfaces, etc., and achieve the effect of improving service life, not easy to aging, and reducing electromagnetic interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

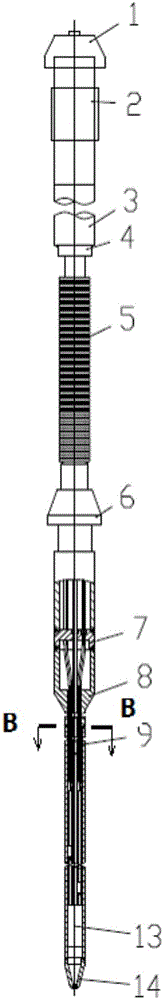

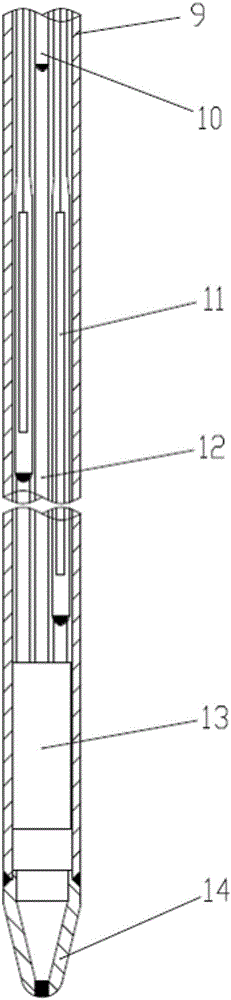

[0041] Such as Figure 1 to Figure 3 As shown, a core instrument bushing assembly for a nuclear power plant includes a dust cover 1, an electrical connector 2, a rear shell 3, a connecting pipe 4, a flexible metal conduit 5, a header connecting pipe 6, a header 7, and a joint 8. Shell 9, armored thermocouple 10, neutron detector 11, extension section 12, extension section joint 13, bullet end plug 14.

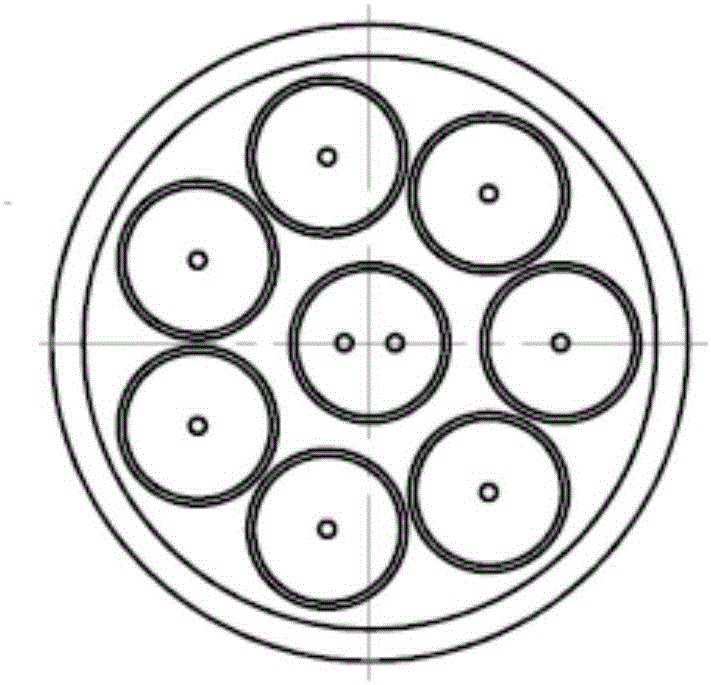

[0042] The armored thermocouple 10 and multiple neutron detectors 11 are fixed to the manifold 7 by brazing, and the armored thermocouple 10 and neutron detectors 11 are welded together with the extension section 12 and the extension section joint 13 . The neutron detector 11 is a self-sufficient neutron detector, consisting of emitters, collectors, insulators and cables, the length of the longest neutron detector 11 among the multiple neutron detectors 11 corresponds to the height of the entire reactor core, The lengths of the remaining neutron detectors 11 decrease at equal ...

Embodiment 2

[0045] Such as Figure 2 to Figure 8 As shown, the difference between Embodiment 2 and Embodiment 1 is that one or more armored thermocouples 10 are provided, and one or more liquid level monitoring thermocouples 15 are additionally provided. Liquid level monitoring thermocouple 15 is fixed together with armored thermocouple 10 brazing 16 ( Figure 6 )

[0046] Multiple armored thermocouples 10 are used to monitor the temperature measurement points of the coolant at the inlet of the fuel assembly, the temperature measurement points of the local area of the fuel element outlet of the fuel assembly, the temperature measurement points of the TBC outlet of the fuel assembly, and the temperature measurement points under the reactor top cover.

[0047] The liquid level monitoring thermocouple 15 is composed of TPIU with electric heater and thermocouple TP without electric heater. Under normal working conditions, both TPIU with electric heater and thermocouple TP without electric he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com