Water cooling system for linear accelerator

A technology of linear accelerator and water cooling system, applied in the direction of linear accelerator, cooling/ventilation/heating transformation, electrical components, etc., can solve the problem of affecting the temperature control accuracy, the hysteresis of the dynamic adjustment of the temperature control object by the refrigerator, etc., to solve the lag Sexual problems, the effect of precise temperature control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with the best examples shown in the accompanying drawings for further details:

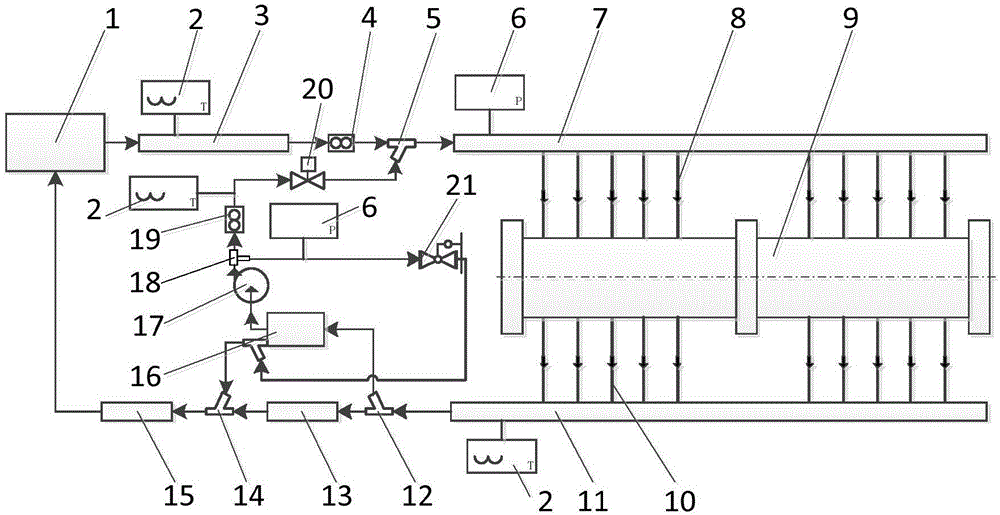

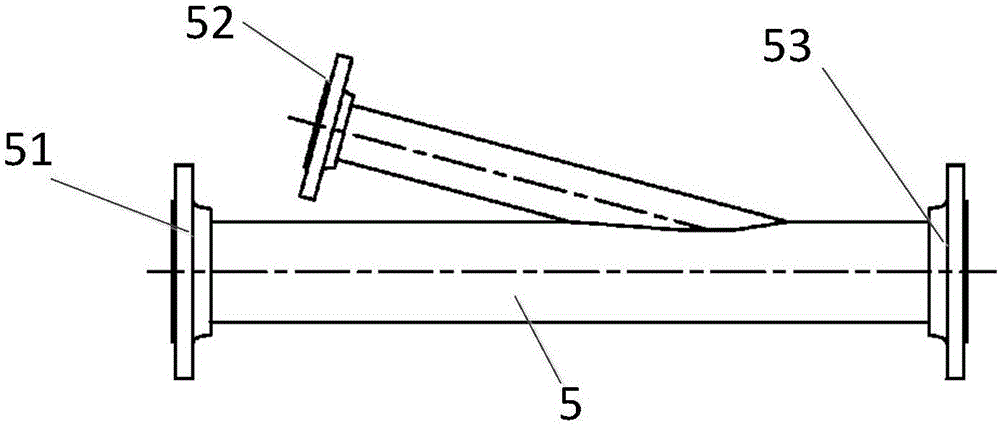

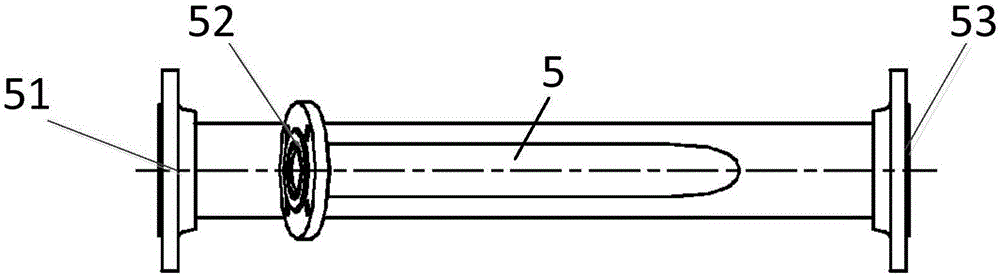

[0019] Such as Figures 1 to 6 As shown, the water cooling system for a linear accelerator is characterized in that it includes a main flow circuit and a water mixing circuit. The main flow circuit includes a refrigerator 1, and the output cooling water of the refrigerator 1 passes through the water inlet main pipe 3 in turn. 1. The first flow meter 4 and the water mixing tee 5 are connected to the water separator 7, the water separator 7 is connected to the linear accelerator 9 through the first water pipe group 8, and the linear accelerator 9 is connected to the water collector 11 through the second water pipe group 10, and the water collector The device 11 is connected to the refrigerator 1 sequentially through the first three-way 12, the first return water main pipe 13, the second three-way 14 and the second water return main pipe 15; the mixed water circuit include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com