Drilling device

A drilling device and water inlet device technology, applied in the direction of working accessories, manufacturing tools, stone processing equipment, etc., can solve the problems of drilling deviation, drill bit slippage, and the inability to rinse the glass surface immediately, so as to improve the drilling quality and improve the efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

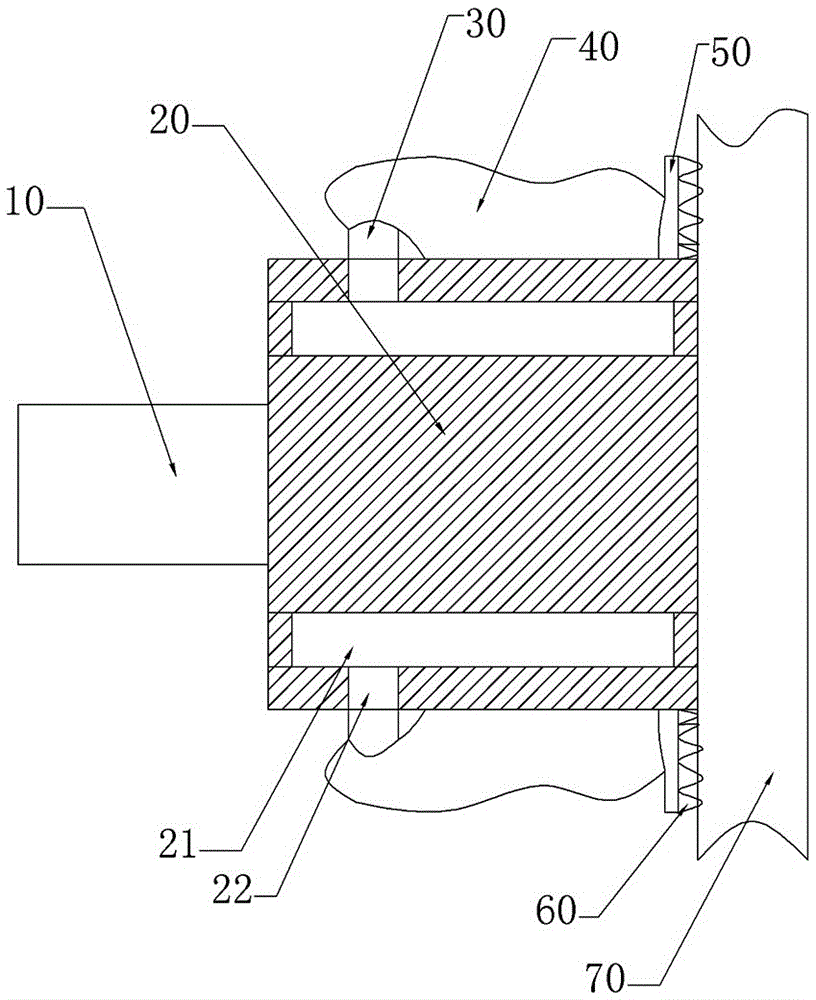

[0020] Basic as attached figure 1 Shown: a kind of drilling device in this scheme, comprises drill bit body, and drill bit body comprises hand-held part 10 and drilling part 20, and hand-held part 10 and drilling part 20 are connected by bearing rotation, and there is hole in drilling part 20 Cavity 21, two water inlets 22 are opened on the outside of the cavity 21, the water inlet 22 is connected with the water inlet pipe 30 by the internal thread, the water inlet pipe 30 is connected with an annular elastic bag 40, the elastic bag 40 is filled with cold water, the right end of the elastic bag 40 Bonding with width is the fixed part 50 of 10cm, and fixed part 50 covers elastic bag 40 completely, and blower is installed in fixed part 50, and the blower mouth of blower is away from drilling part 20, and fixed part 50 right-hand side is bonded with cleaning brush 60.

[0021] First, the drilling part 20 of the drill body is in contact with the glass 70, and then the drill bit is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com